Test Structure for Breaking Strength of Thin Film Materials

A technology for testing structures and thin-film materials, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that it is difficult to realize direct loading of test signals and electrical detection, etc., to achieve stable test process and test parameter values, and calculation methods Simple, low-equipment-required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

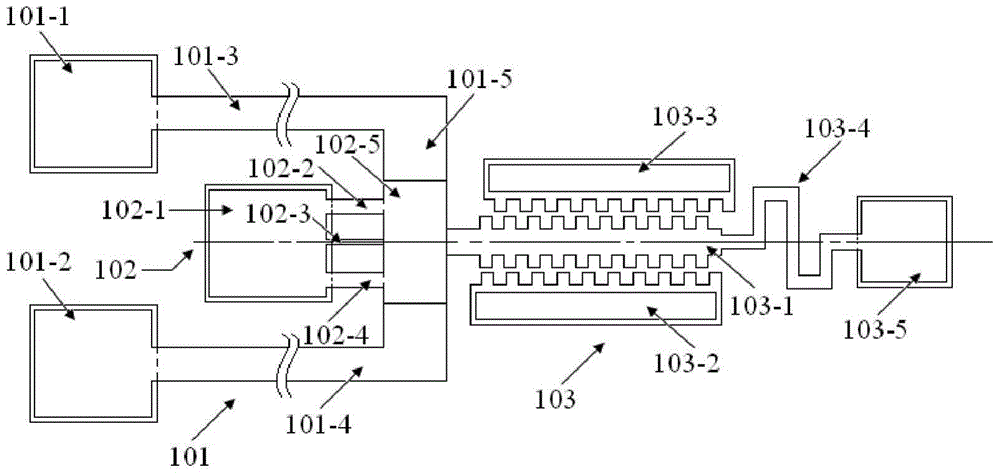

[0019] Attached below figure 1 The present invention will be further described.

[0020] The invention provides a test structure for measuring the breaking strength of thin film materials. The test structure consists of three parts: a thermal expansion drive unit 101; a micrometer vernier 103 with a damping structure; and a tensile beam unit 102 made of the film material to be tested. Wherein, the main body material of the thermal expansion driving unit 101 and the micrometer vernier 103 with a damping structure is polysilicon.

[0021] The thermal expansion driving unit 101 is a gate-shaped structure, including two anchor areas, namely the first anchor area 101-1, the second anchor area 101-2, two horizontal long beams, namely the first horizontal long beam 101-3, the second horizontal long beam Two horizontal long beams 101-4, one vertical wide beam 101-5. The right ends of the two horizontal long beams are respectively vertically connected to the upper and lower ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com