Ultra-high temperature heat-insulating property testing device and method

A test device and ultra-high temperature technology, applied in the field of ultra-high temperature thermal insulation performance test devices, can solve the problems of high construction and use costs, sample airflow erosion, long test cycle and other problems, and achieve convenient operation, rapid temperature rise and fall, and shortened test effect of cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner. Existing technologies can be adopted for the parts not mentioned in the embodiments.

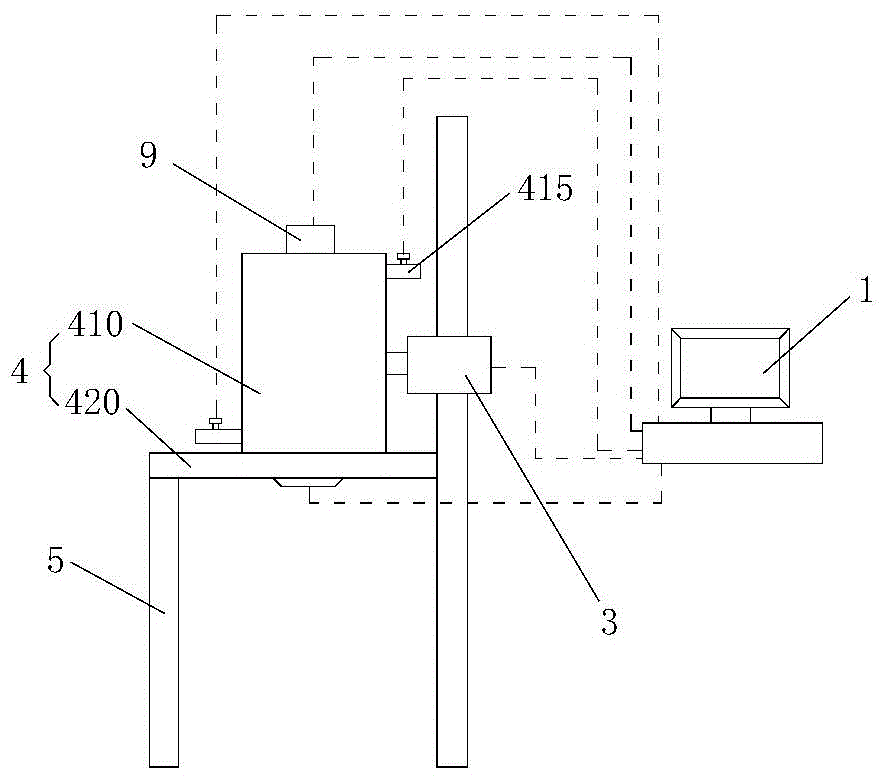

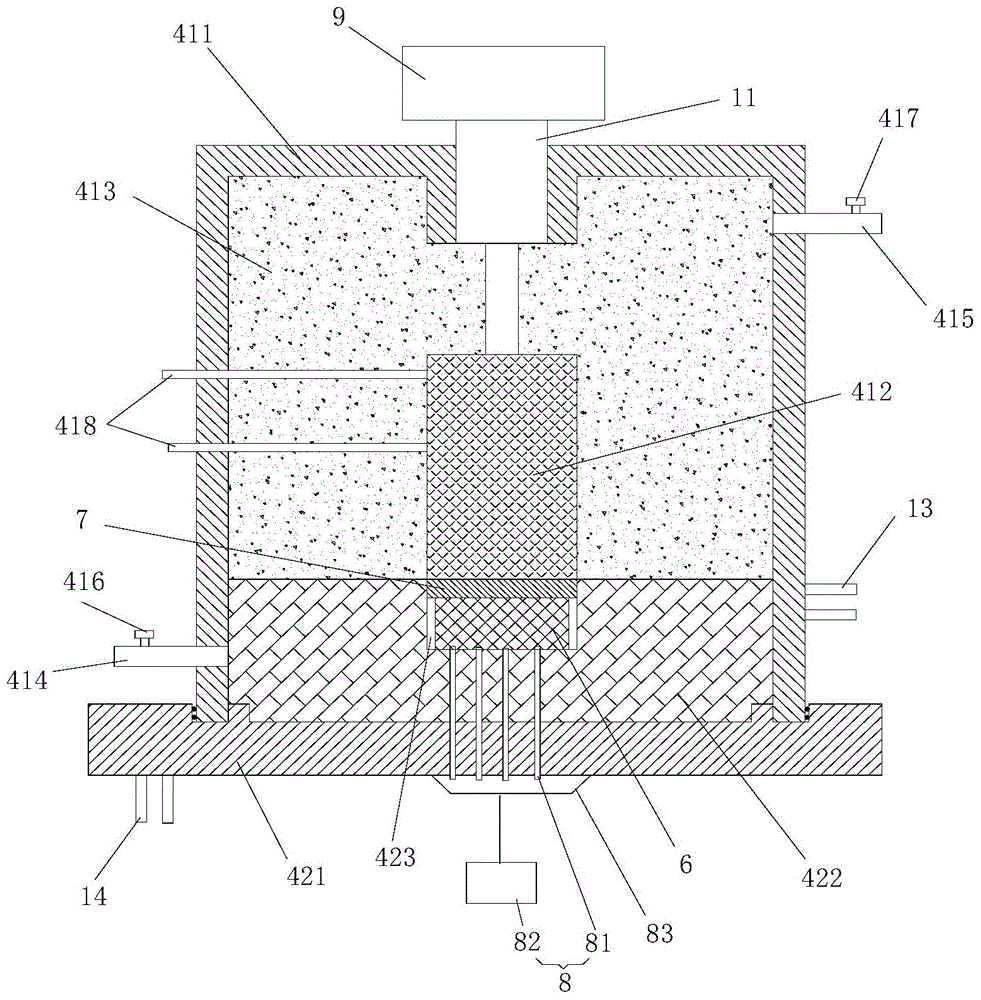

[0035] figure 1 It is a schematic structural diagram of the ultra-high temperature heat insulation performance test device of the embodiment of the present invention; figure 2 It is a structural schematic diagram of a heating furnace according to an embodiment of the present invention. figure 1 The dotted line indicates the electrical connection such as figure 1 and figure 2 As shown, the ultra-high temperature heat insulation performance tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com