Unstable-state superhight-temperature heat insulating property testing device and method

A test device and ultra-high temperature technology, applied in the field of thermal insulation performance testing, can solve the problems of non-steady-state closed ultra-high temperature thermal insulation performance testing device, long test period, low heat flow density, etc. Test cycle, the effect of high degree of simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below with reference to the drawings and specific embodiments, but it is not intended to limit the present invention. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. In addition, specific features, structures, or characteristics in one or more embodiments may be combined in any suitable form. Existing technologies can be used for all the remaining parts in the embodiments.

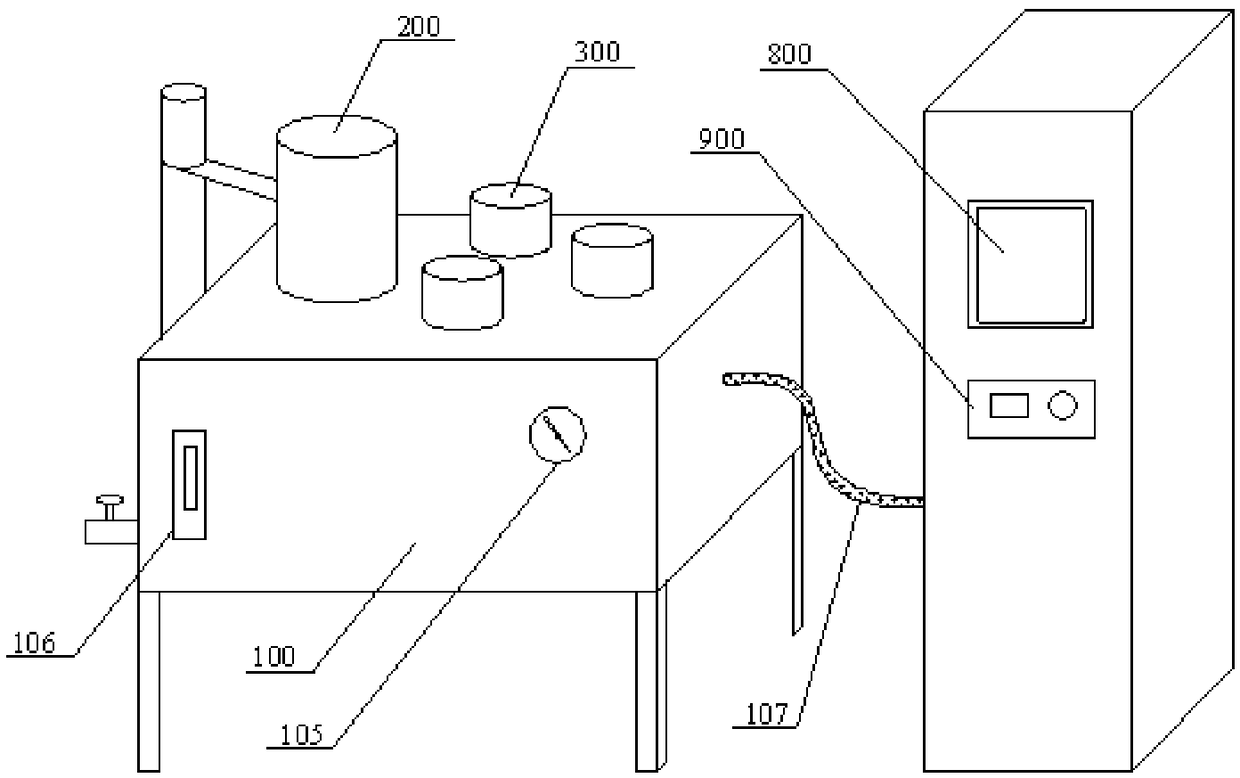

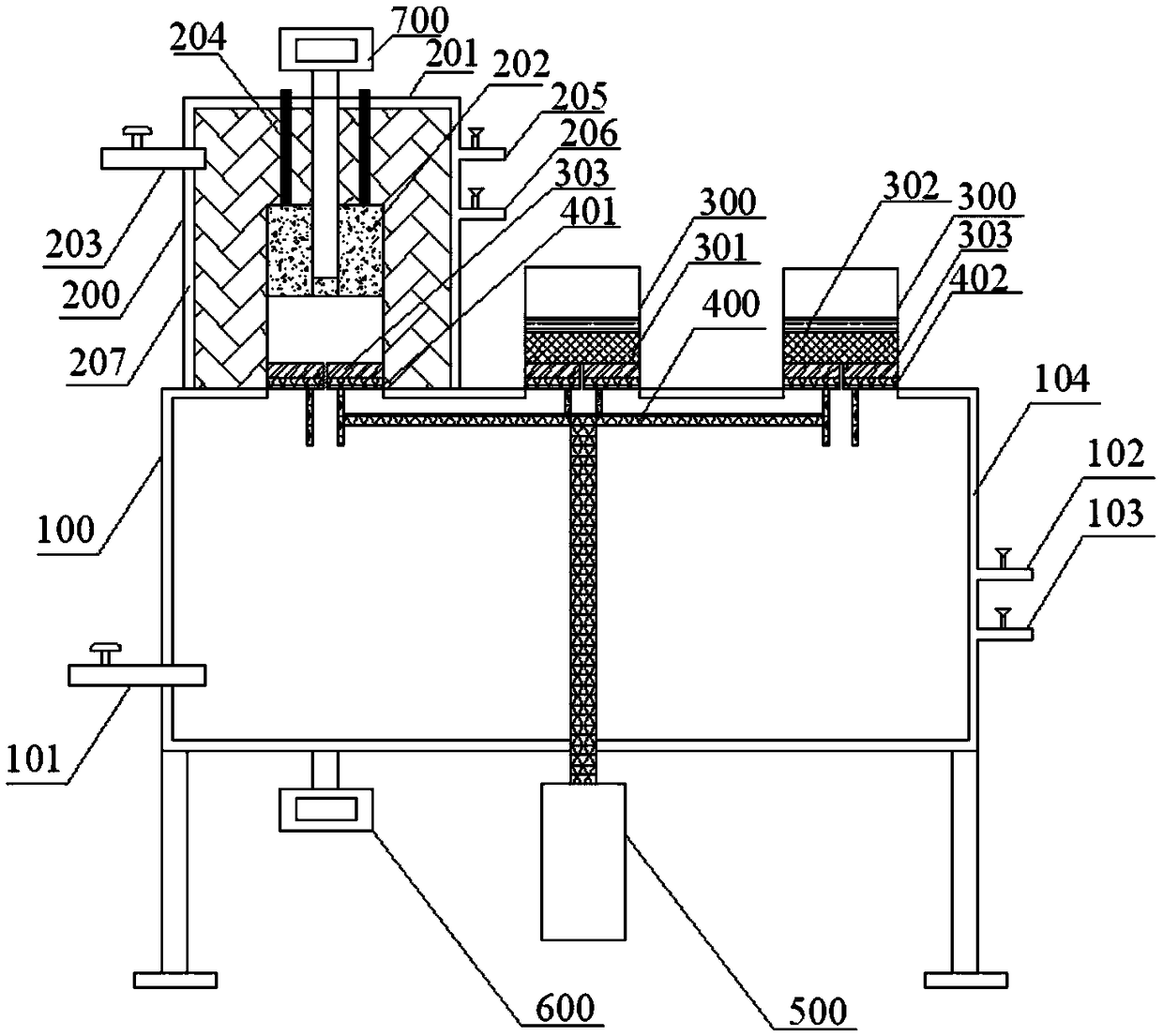

[0045] figure 1 It is one of the structural schematic diagrams of the non-steady state ultra-high temperature thermal insulation performance test device of the embodiment of the present invention; figure 2 It is the second structural diagram of the non-steady ultra-high temperature thermal insulation performance test device of the embodiment of the present invention. Such as figure 1 with figure 2 As shown, an ultra-high temperature thermal insulation performance test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com