Method for improving packaging performance of electrowetting device and electrowetting device

A device packaging and electrowetting technology, applied in the field of electrowetting, can solve problems such as ink leakage, reduced device life and output, poor device packaging performance, etc., and achieve the effect of simple process, reliable quality and excellent packaging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

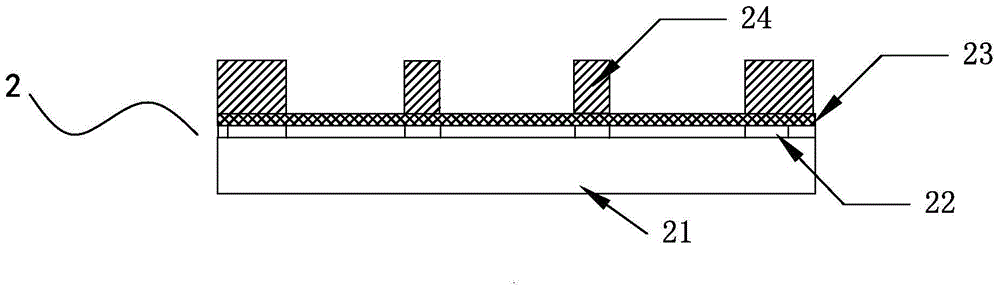

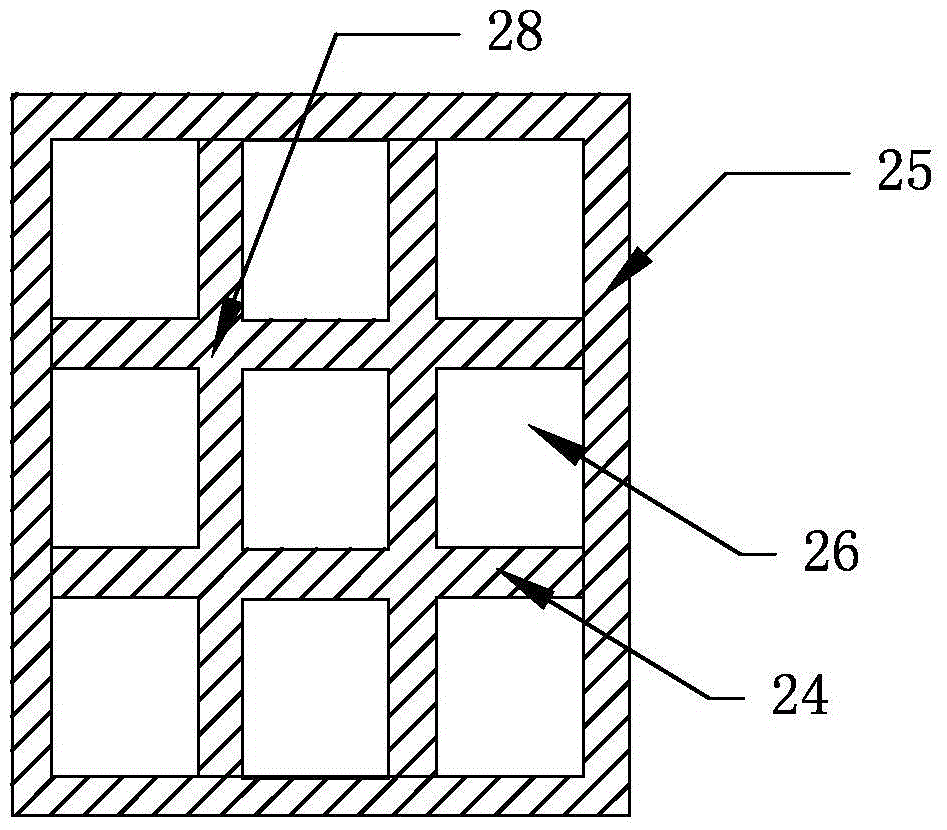

[0045] The pixel wall 24 can be prepared by methods well known to those skilled in the art. For example, the photoresist material can be coated in one or more steps. The coating method can be, but not limited to, spin-coating, roller coating. -coating, slit-coating, dip-coating, spray-coating, blade-coating, etc. Then the film is further pre-baked, UV light exposure and post-exposure baking (PEB), and then developed to obtain the pixel wall 24. In order to avoid the phenomenon of driving ink jumping, it is necessary to ensure that the water droplets on the surface of the pixel wall 24 are in contact Angle ≤ 50 degrees.

[0046] Preferably, the method in the invention patent of 201410665529.5 submitted by the present inventor is used to prepare the pixel wall 24, that is, the pixel wall 24 is formed of a hydrophilic SOG material or the pixel wall has a layer of hydrophilic SOG material on the surface Therefore, the surface of the pixel wall 24 thus obtained has high hydrophilicit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com