Three-dimensional model-based spacecraft assembly information modification system and modification method

A technology for spacecraft final assembly and three-dimensional model, applied in the field of spacecraft final assembly information change system based on three-dimensional model, can solve the problem of reducing work efficiency, inability to perform operation simulation, design data, process data and on-site production data unable to establish correlation, etc. problems, to achieve the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be clearly and completely described below with reference to the accompanying drawings and specific embodiments.

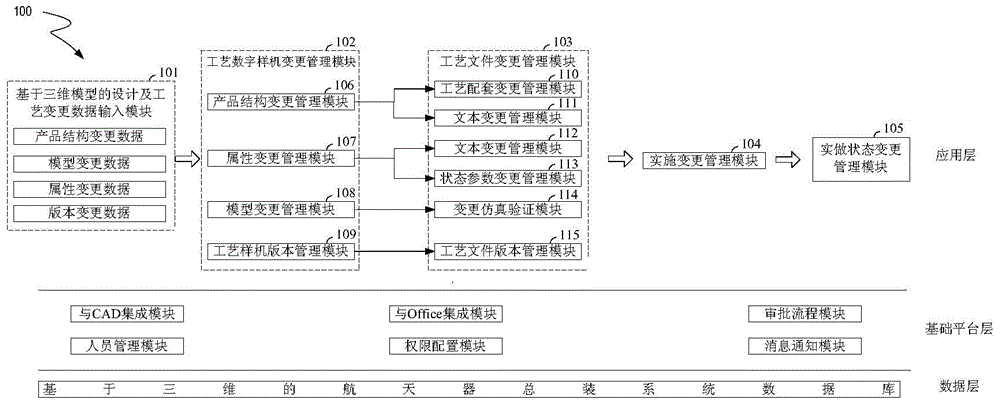

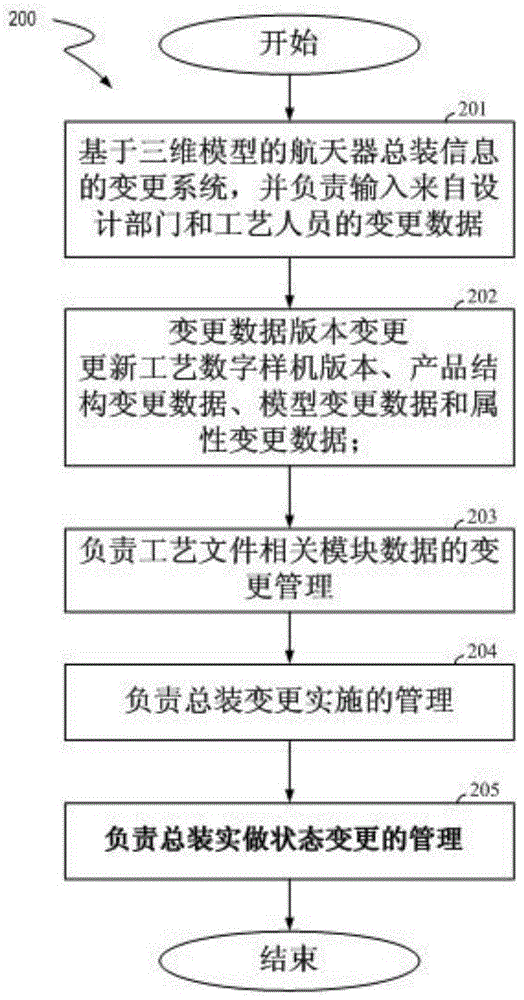

[0013] The invention provides a three-dimensional model-based spacecraft assembly information change system and a change method. It is proposed to establish an association relationship between a change data input module, a process digital prototype management module, a process management module and an implementation state management module. The interface realizes the associative control of the change of the final assembly state, forms a data package of the change of the final assembly state of the spacecraft, and improves the efficiency and quality of the spacecraft development.

[0014] figure 1 Shown is the structure diagram of the three-dimensional model-based spacecraft assembly information changing system 100 of the present invention. The spacecraft assembly information change system 100 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com