High-temperature melt releasing device

A technology for releasing devices and melts, which can be used in emergency protection devices, greenhouse gas reduction, reactors, etc., and can solve problems such as ineffectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

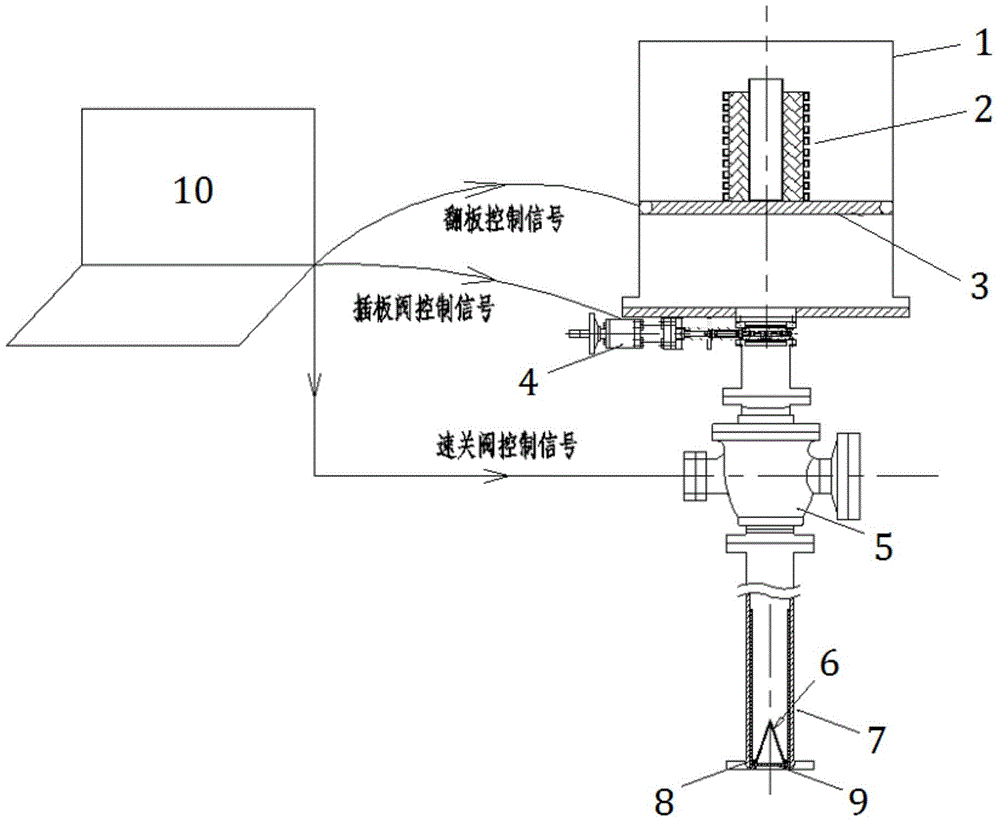

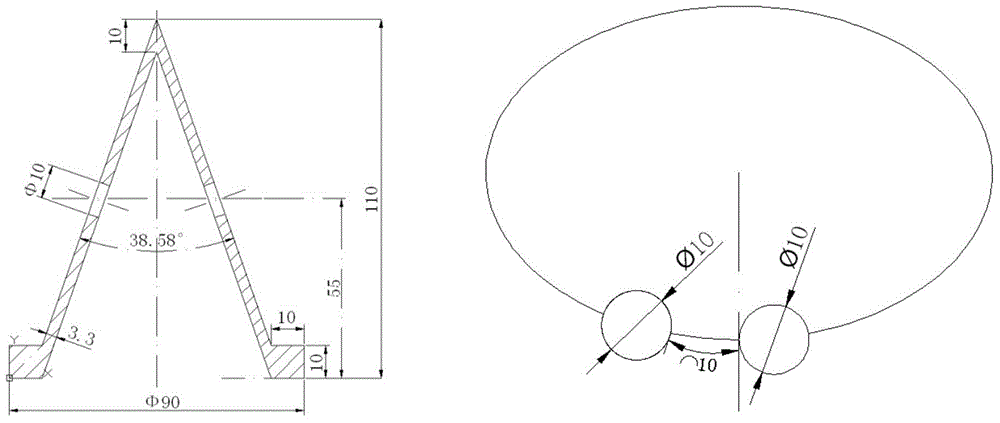

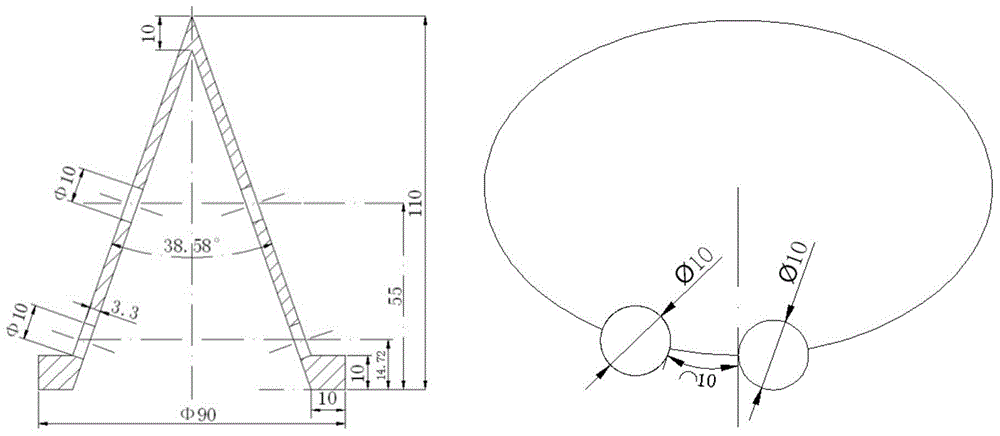

[0025] Such as figure 1 As shown, this embodiment includes: a pneumatic support mechanism and an impact mechanism arranged in sequence under the heating system 2 in the vacuum chamber 1, wherein the impact mechanism includes: a pipeline 7 connected to the pneumatic support mechanism and a pipeline 7 fixedly arranged inside the pipeline 7 The graphite cone 6, when the molten material passes through the graphite cone 6, the pneumatic support mechanism is completely closed in the time gap.

[0026] The pneumatic support mechanism includes: a pneumatic support flap 3 located under the melt heating device, and a flapper valve 4 and a quick-closing valve 5 which are airtightly connected to it in turn, wherein: the pneumatic support flap 3 and the flapper valve 4 and the quick-closing valve 5 are respectively connected with the console 10 and receive corresponding control signals.

[0027] The pneumatic support flap 3 is located at the bottom of the graphite crucible. Since the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com