Micro-channel heat exchanger for drop-shaped pin fins

A micro-channel heat exchanger, drop-shaped technology, applied in the direction of electrical components, electrical solid devices, semiconductor devices, etc., can solve the problems of high heat flux heat dissipation, etc., to increase the heat transfer area, enhance the heat transfer effect, heat dissipation powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The working process and effect of the inventive droplet-shaped turbulent element microchannel heat exchanger will be further described and verified below in conjunction with the structural drawings.

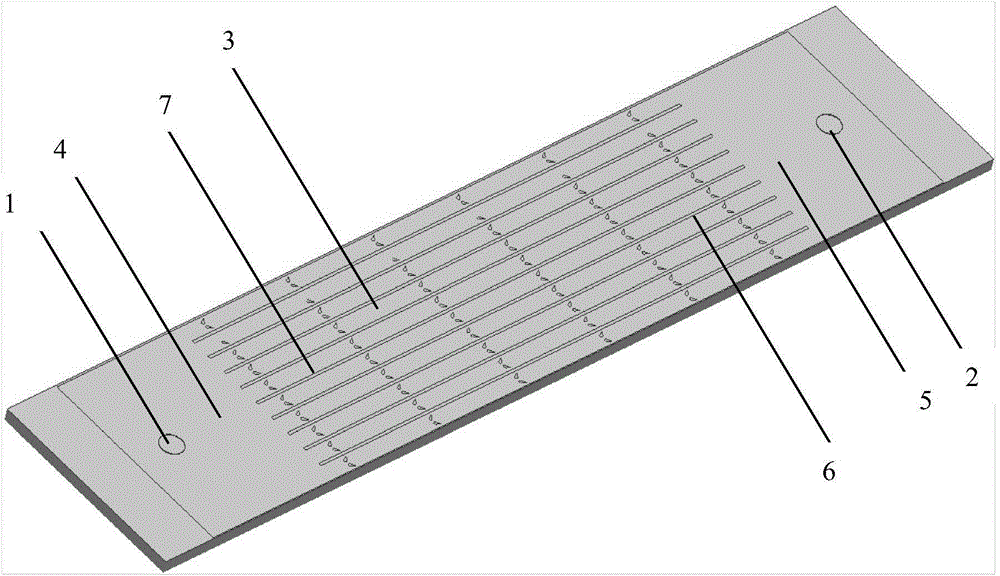

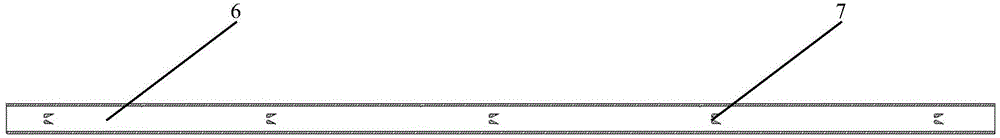

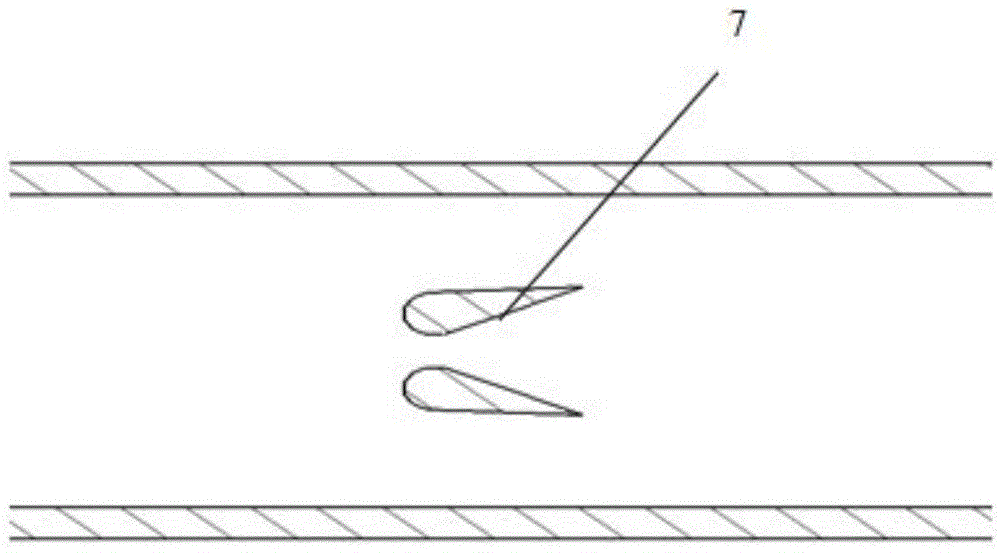

[0015] figure 1 It is a schematic diagram of the three-dimensional general outline of the drop-shaped turbulent element microchannel heat exchanger. The drop-shaped turbulence element micro-channel heat exchanger mainly includes channel cooling medium inlet 1, cooling medium outlet 2, glass cover plate 3, channel inlet end 4, channel outlet end 5, cooling silicon-based channel 6, water drop-shaped turbulence Stream element 7 constitutes. In order to verify that the invention has a better heat transfer effect than conventional channels, Table 1 lists the thermal resistance R, Nusselt number Nu, and heat transfer coefficient h of the heat exchanger for a given Reynolds number Re to characterize heat transfer. The parameters of the effect, and compared with the regular smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com