Polymer lithium ion battery with fixed diaphragm and manufacturing method thereof

A lithium-ion battery and polymer technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc., can solve problems such as inability to use CID protection, shrinkage of positive and negative electrode diaphragms, and direct contact between positive and negative electrodes. , to avoid thermal runaway, improve cycle life, and not easy to shrink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

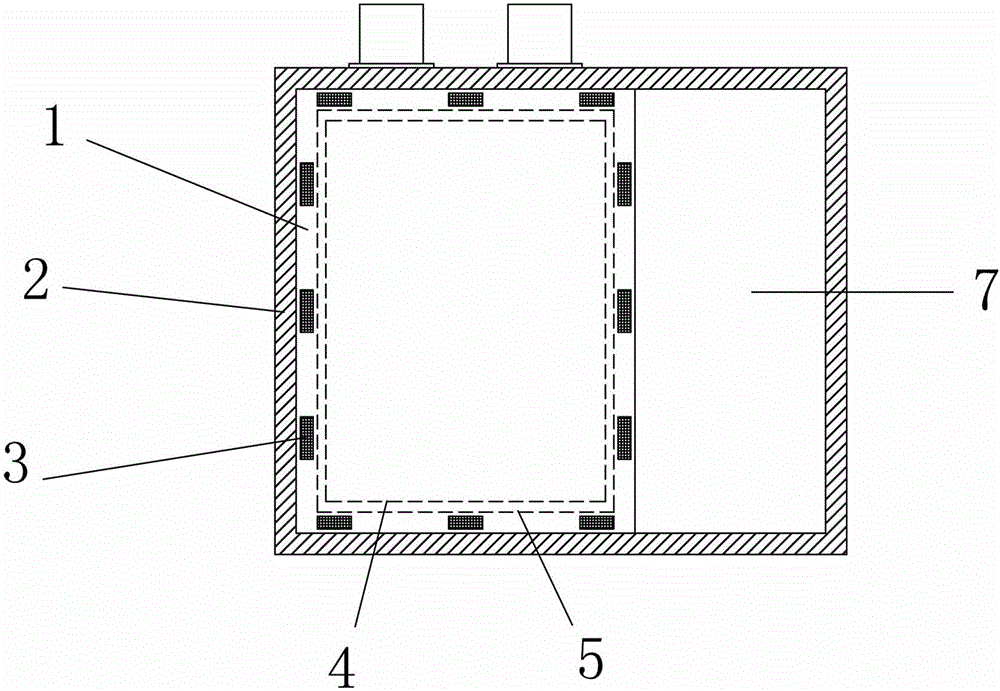

[0038] Only on the bottom side of the polymer battery, use three diaphragm fixing points with an area of 5*20mm to bond the diaphragm and aluminum-plastic film together, and there are no diaphragm fixing points on the other three sides.

Embodiment 2

[0040] On the bottom and top sides of the polymer battery, three diaphragm fixing points with an area of 5*20mm are used to bond the diaphragm and the aluminum-plastic film together, and there are no diaphragm fixing points on the other two sides.

Embodiment 3

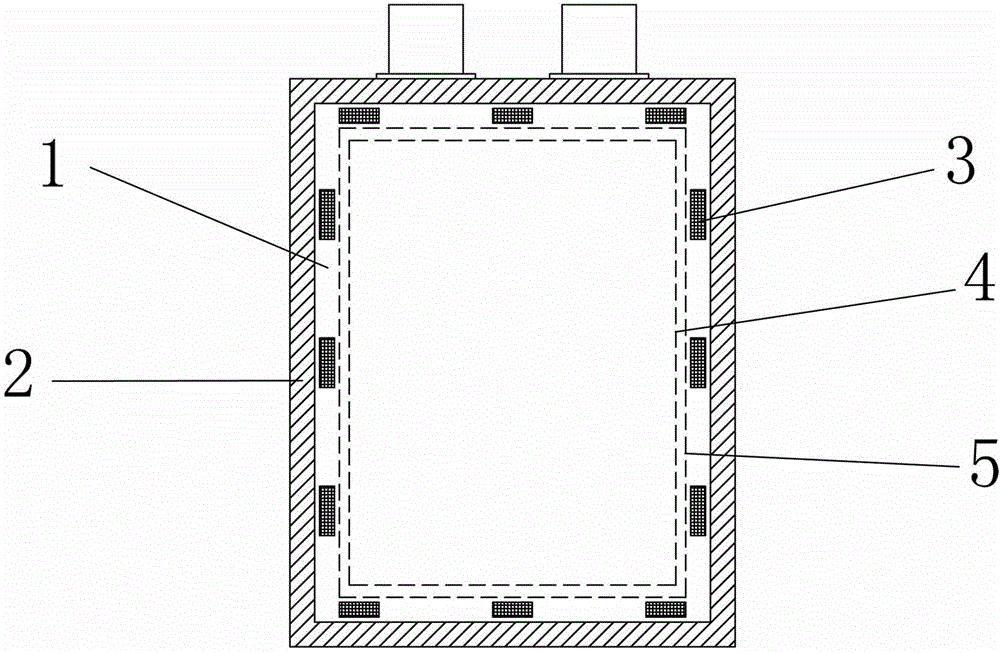

[0042] The bottom edge, top edge and two sides of the polymer battery are respectively bonded to the separator and the aluminum-plastic film with three separator fixing points with an area of 5*20mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap