Direct methanol fuel cell membrane electrode structure and preparation method thereof

A methanol fuel cell, membrane electrode structure technology, applied in battery electrodes, structural parts, circuits, etc., to achieve the effect of ensuring stability and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

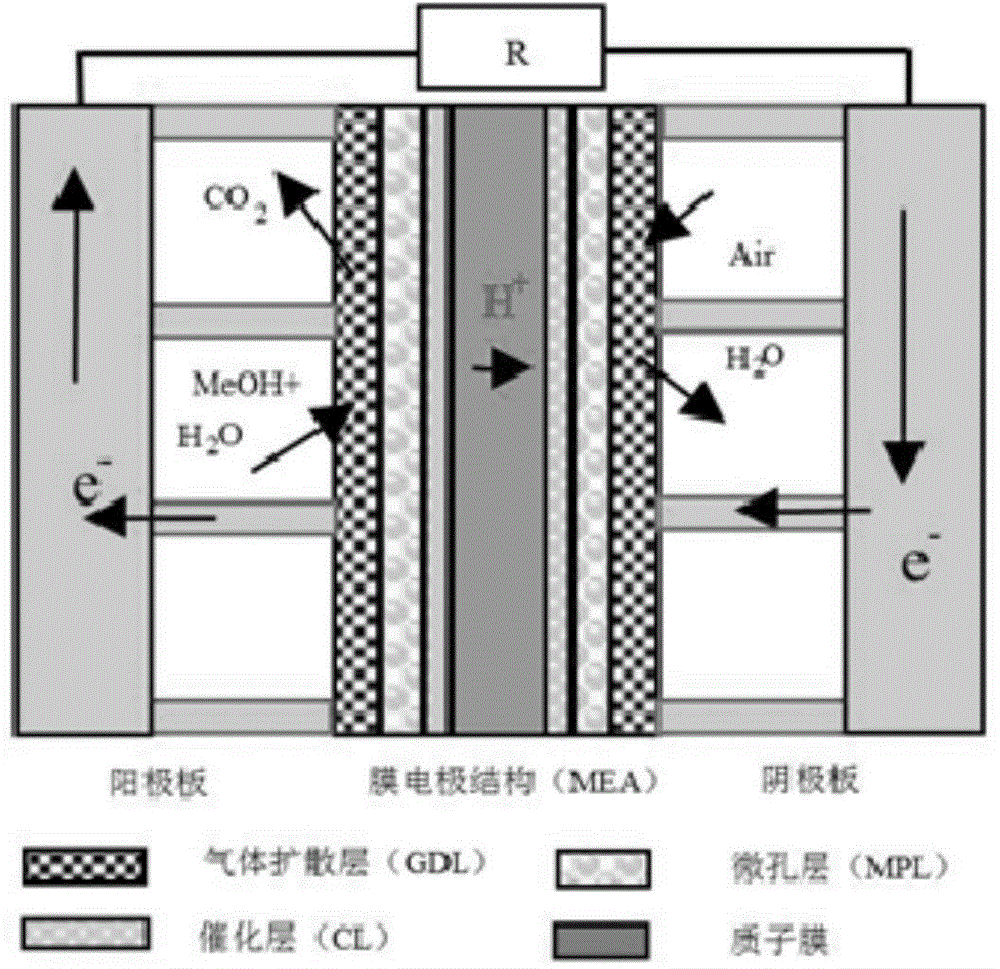

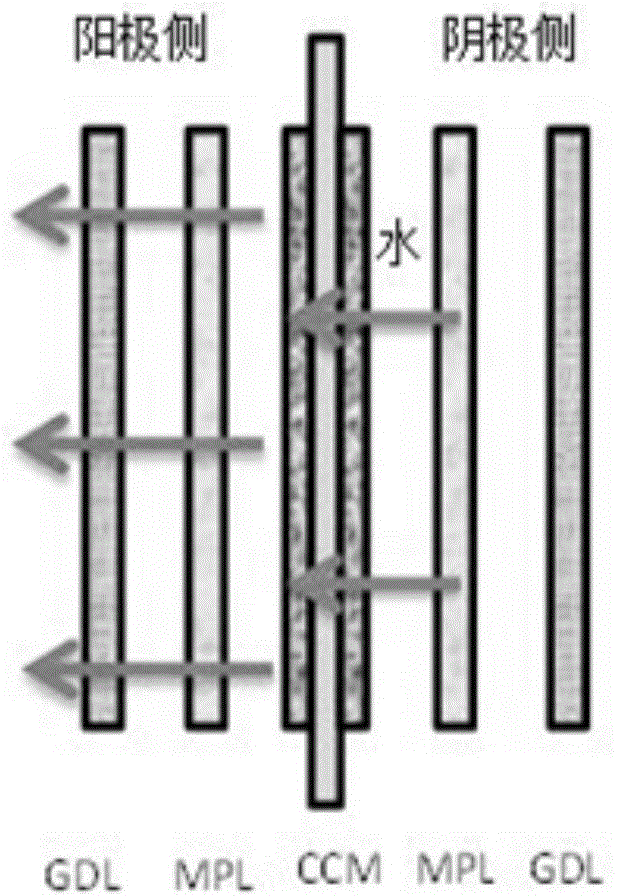

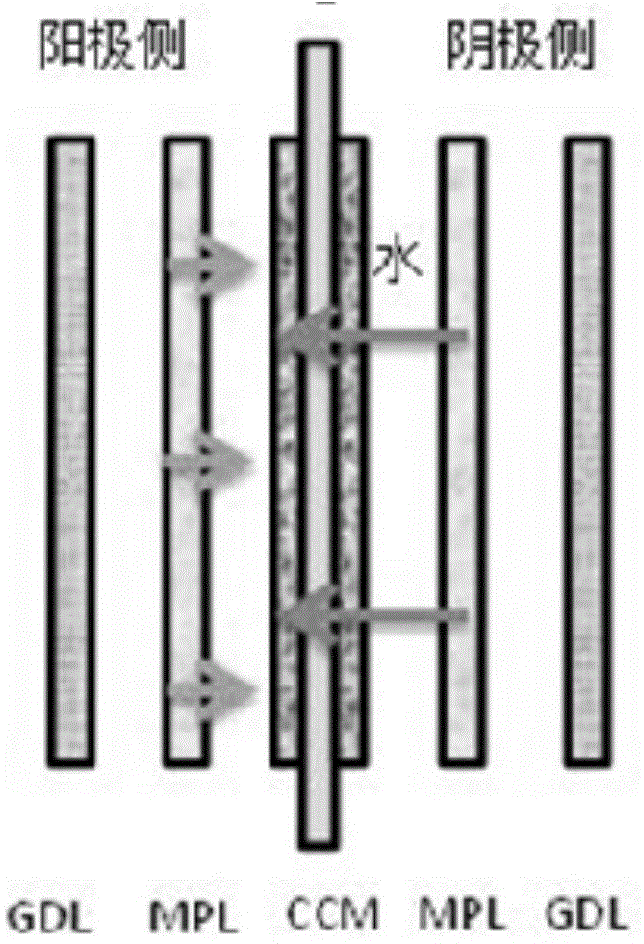

[0029] Reference attached Figure 2b :

[0030] The DMFC membrane electrode structure of the present invention includes an anode gas diffusion layer, a microporous layer, a catalytic layer, a proton membrane, a cathode catalytic layer, a microporous layer, and a gas diffusion layer. The proton membrane is in the center and is characterized in that: the anode The gas diffusion layer and the cathode gas diffusion layer are made of hydrophobically treated carbon paper, carbon cloth, or other porous conductive plates, with a PTFE content of 1-50wt%; the anode gas diffusion layer is coated with an anode microporous layer and a cathode gas diffusion layer The cathode microporous layer is coated on the surface, and the anode microporous layer and the cathode microporous layer have the same PTFE content and the same micropore diameter.

[0031] Further, the thickness of the proton membrane is 1-2 mil; the PTFE content of the anode microporous layer and the cathode microporous layer are bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com