Method for modifying tobacco activated carbon by virtue of ozone and application of modified activated carbon

A technology for activated carbon and cigarettes, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unstable effect and unclear mechanism, and achieve the effect of simple and easy method, low cost, and feasible practical application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1 Ozone Modification of Activated Carbon for Tobacco

[0062] S1. Activated carbon pretreatment:

[0063] Take XFP01 activated carbon, wash it with a certain amount of distilled water several times to remove surface ash components and impurities, filter it with suction, and dry it at 100°C for 24 hours.

[0064] S2. Activated carbon modification:

[0065] Take 1 g of the treated activated carbon and put it into a glass reactor. Add 20mL of 2mol / L sulfuric acid, the sample is marked as XF / H 2 SO 4 . Then pass O 3 (10g / h), the reaction time is 10min, 20min, 1h, 2h respectively. Finally, filter with suction, and dry the filter cake at 100°C for 24 hours.

[0066] The test results are as follows:

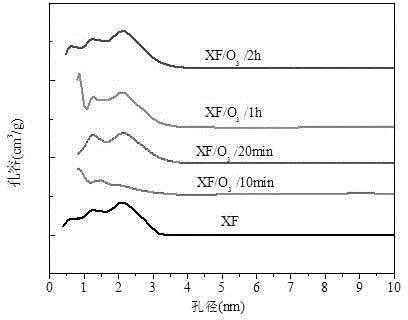

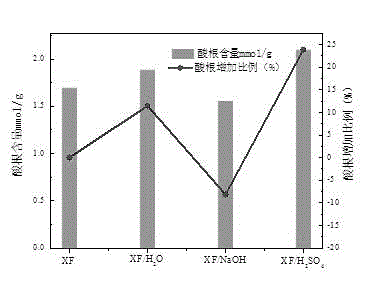

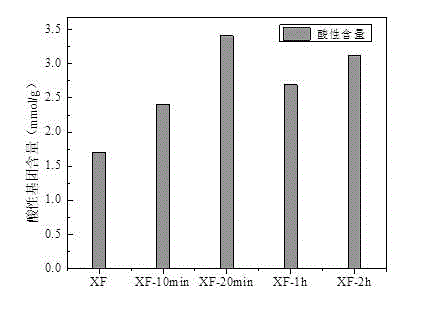

[0067] Specific Surface and Pore Structure Test of Modified Activated Carbon

[0068] Table 1 shows the results of specific surface area and pore structure of activated carbon after different ozone modification times. It can be seen from Table 1 that when the mod...

Embodiment 2

[0109] Example 2 Applied evaluation test

[0110] S1. Activated carbon pretreatment:

[0111] Take XFP01 activated carbon, wash it with a certain amount of distilled water several times to remove surface ash components and impurities, filter it with suction, and dry it at 100°C for 24 hours.

[0112] S2. Activated carbon modification:

[0113] Take 1 g of the treated activated carbon and put it into a glass reactor. Add 20mL of 2mol / L sulfuric acid, the sample is marked as XF / H 2 SO 4 . Then pass O 3 (10g / h), the reaction time is 10min, 20min, 1h, 2h respectively. Finally, filter with suction, and dry the filter cake at 100°C for 24 hours. Get XF / 10min (modification time 10min), XF / 20min (modification time 20min), XF / 1h (modification time 60min) and XF / 2h (modification time 120min).

[0114] The above-mentioned smoke activated carbon sample and comparative activated carbon XF were respectively adsorbed 2-cyclopentenone according to the aforementioned method.

[0115] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com