A kind of preparation method of methanol dehydration production dimethyl ether catalyst

A methanol dehydration and catalyst technology, which is applied in the direction of ether preparation, dehydration of hydroxyl-containing compounds to prepare ether, chemical instruments and methods, etc., can solve the problems of selectivity and activity decline, many by-products, low initial temperature, etc., and achieve high activity And anti-coke performance, improve the overall performance, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

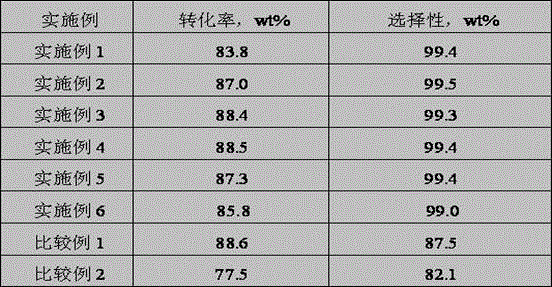

Examples

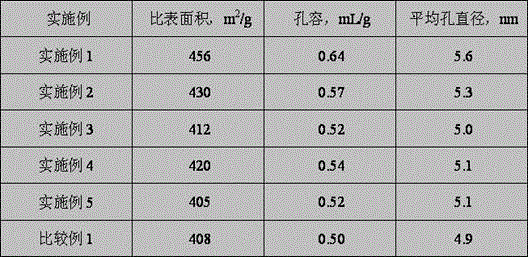

Embodiment 1

[0033] (1) Catalyst preparation:

[0034] Weigh 145.8g of cetyltrimethylammonium bromide and 205g of citric acid to form a mixed solution, add 302mL tetraethyl orthosilicate to the mixed solution, stir for 2 h, and then stir at 70°C until coagulation Gel, the gel was aged at room temperature for 12 h, dried at 100 °C for 8 h, and then heat-treated at 200 °C for 2 h, the resulting solid was added to an aqueous solution containing 25.6 g of citric acid, stirred at 70 °C until the solution was evaporated to dryness, The obtained material was immersed in ammonium carbonate solution for 10 minutes, filtered and dried at 60°C, then added to a mixed aqueous solution containing 13.3g of lanthanum nitrate and 15.6g of phosphotungstic acid, stirred at 70°C until the solution was evaporated to dryness, and then The obtained solid was dried at 110°C for 8.0 h, and then calcined at 500°C for 3.0 h to obtain (NH 4 ) 0.5 h 2.5 PW 12 o 40 -La 2 o 3 / SiO 2 Catalyst, where La 2 o 3 Th...

Embodiment 2

[0040] Weigh 200g of cetyltrimethylammonium bromide and 105.7g of citric acid to make a mixed solution, add 250mL tetraethyl orthosilicate into the mixed solution, stir for 2 h, and then stir at 70°C until coagulation Gel, the gel was aged at room temperature for 12 h, dried at 100 °C for 8 h, and then heat-treated at 200 °C for 2 h, the resulting solid was added to an aqueous solution containing 42.3 g of citric acid, stirred at 70 °C until the solution was evaporated to dryness, The obtained material was immersed in ammonium carbonate solution for 10 minutes, filtered and dried at 60°C, then added to a mixed aqueous solution containing 37.2g of lanthanum nitrate and 20.8g of phosphotungstic acid, stirred at 70°C until the solution was evaporated to dryness, and then The obtained solid was dried at 110 °C for 8.0 h, and then calcined at 450 °C for 3.0 h to obtain (NH 4 ) 0.7 h 2.3 PW 12 o 40 -La 2 o 3 / SiO 2 Catalyst, where La 2 o 3 The content is 14wt%, (NH 4 ) 0....

Embodiment 3

[0043] Weigh 316g of cetyltrimethylammonium bromide and 62.4g of citric acid to form a mixed solution, add 246mL tetraethyl orthosilicate into the mixed solution, stir for 2 h, and then stir at 70°C until coagulation Gel, the gel was aged at room temperature for 12 h, dried at 100 °C for 8 h, and then heat-treated at 200 °C for 2 h, the resulting solid was added to an aqueous solution containing 62.4 g of citric acid, stirred at 70 °C until the solution was evaporated to dryness, The obtained material was immersed in ammonium carbonate solution for 10 minutes, filtered and dried at 60°C, then added to a mixed aqueous solution containing 26.6g of lanthanum nitrate and 25.9g of phosphotungstic acid, stirred at 70°C until the solution was evaporated to dryness, and then The obtained solid was dried at 110°C for 8.0 h, and then calcined at 520°C for 3.0 h to obtain (NH 4 ) 0.2 h 2.8 PW 12 o 40 -La 2 o 3 / SiO 2 Catalyst, where La 2 o 3 The content is 10wt%, (NH 4 ) 0.2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com