Diaphragm coating machine

A coating machine and diaphragm technology, which is applied to devices for coating liquid on surfaces, coatings, pretreatment surfaces, etc., can solve the problems of high diaphragm, poor heat resistance and mechanical strength, and poor mechanical strength of diaphragm coils. , to achieve the effect of highlighting social benefits and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

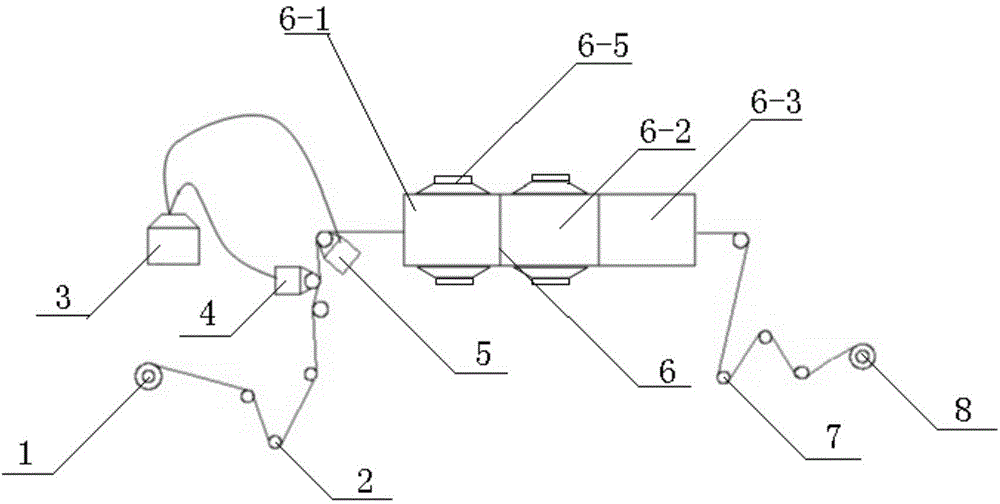

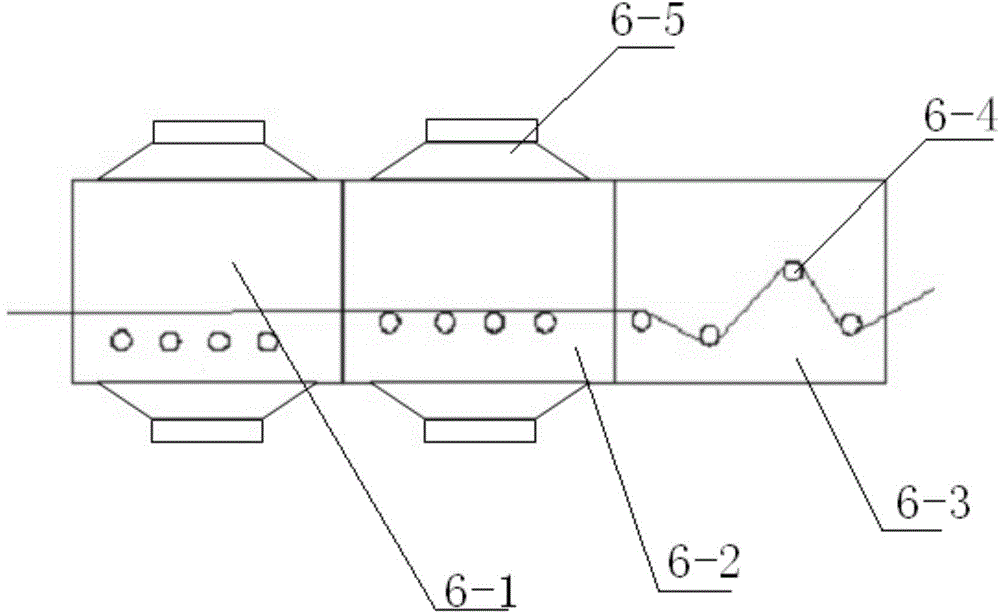

[0020] A diaphragm coating machine, comprising an unwinding roller 1, a traction roller 2, a feeding device 3, an upper station coating roller 4, a lower station coating roller 5, a horizontal oven group 6, a guide roller 7 and a winding Roller 8, the horizontal oven group 6 is formed by horizontally connecting three sections of separate ovens, and each section of separate ovens is provided with a transfer roller 6-4, wherein the first section of separate ovens 6-1 The conveying rollers 6-4 are arranged along the same horizontal plane, and the conveying rollers 6-4 in the second section of the separated oven 6-2 are arranged along the same horizontal plane, and their horizontal height is higher than that of the first section of the separated oven 6-2. - Each conveying roller 6-4 in 1, the height distance between each conveying roller 6-4 in the third section separated oven 6-3 and the bottom surface of the oven is different, so that the diaphragm to be coated is wound in an ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com