High-strength aluminum alloy sheet resistance spot welding molten core inner crack healing method

A technology of resistance spot welding and aluminum alloy, which is applied in the direction of non-electric welding equipment, welding equipment, metal processing, etc., can solve the problems of low efficiency, achieve the effects of promoting healing, improving healing efficiency, and shortening the friction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

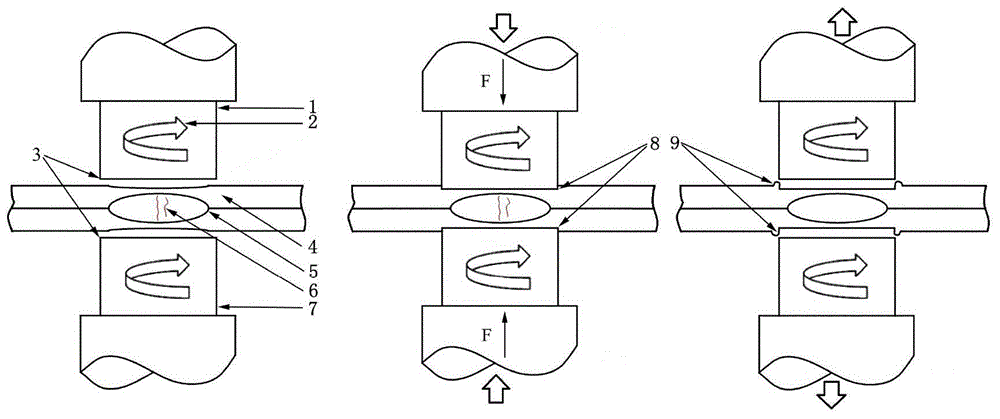

[0021] refer to Figure 1-2 . The specific steps of the healing method of cracks in the high-strength aluminum alloy sheet resistance spot welding nugget of the present invention are as follows:

[0022] 1. Make healing tools.

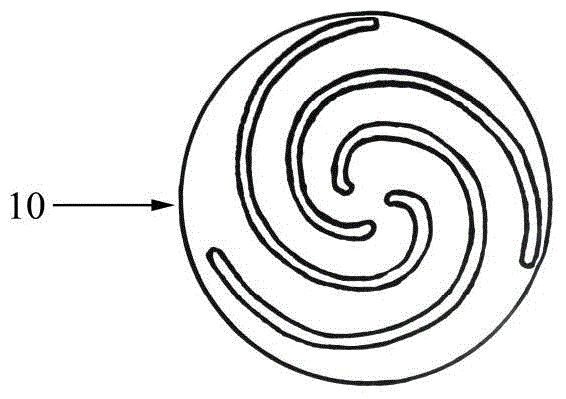

[0023] Both the upper healing tool 1 and the lower healing tool 7 are made of 4Cr5MoSiV1 hot work die steel, and the diameter of the shoulder 3 is 1.5-2.0 times of the indentation diameter of the spot welding joint 4 . In order to promote the metal flow in the area of the spot welding nugget 5 and realize the flow transfer and dynamic recrystallization of the thermoplastic metal around the inner crack 6, three involute grooves with a depth of 0.3mm are processed on the friction surface 10 of the shoulder 3.

[0024] 2. Determine the healing parameters.

[0025] The pressing amount 8 of the upper and lower healing tools 1 and 7 is the same, and its value is slightly greater than the indentation depth of the spot welding joint 4 . Parameters such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com