Pressure head assembly for assembling of engine valve lock plate

An engine valve and indenter technology, applied in the field of tooling and fixtures, can solve the problems of increasing the workload of workers, long production cycle, large free swing of valve springs, etc., and achieves the effect of convenient automatic assembly, solving industry problems and reliable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

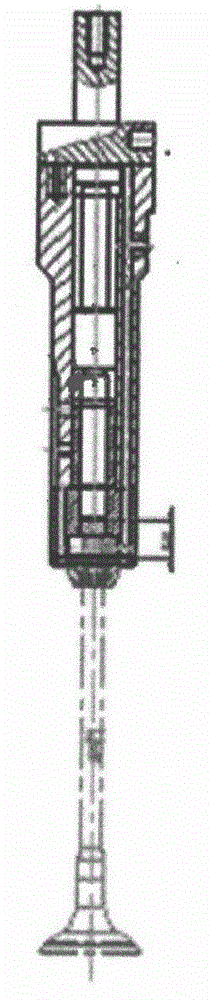

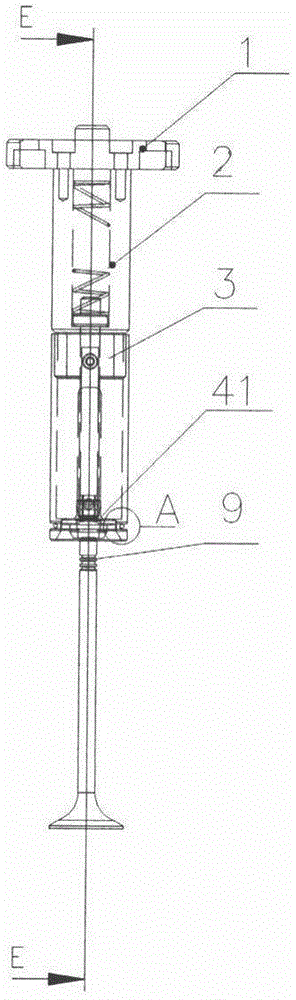

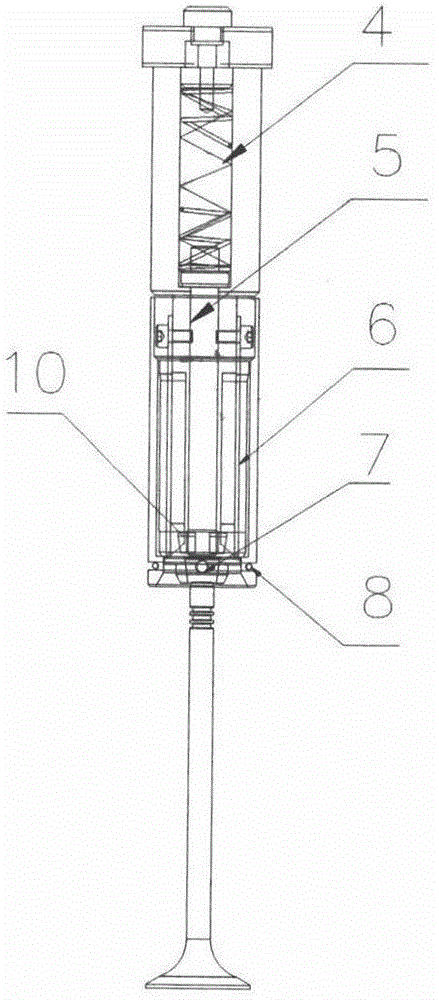

[0012] A pressure head assembly assembled with an engine valve lock plate, the pressure head assembly includes: a cover plate 1, a pressure head 2, a sleeve 3, a spring 4, a guide rod 5, a splint 6, a steel ball 7, a retaining spring 8, a cover The plate 1 is detachably connected to the pressure head 2. The spring 4 and the guide rod 5 are installed in the pressure head 2. One end of the spring 4 is pressed against the upper end of the guide rod 5; the other end is pressed against the cover plate 1, so that the guide rod 5 can move up and down;

[0013] A splint 6 is installed on the outside of the pressure head 2, which is used to clamp the locking plate 10 into the valve groove 9. The sleeve 3 and the pressure head 2 are connected by screws. The lower part of the sleeve 3 is engraved with an annular groove, and there are 2 tapered Hole, 1 steel ball 7 is respectively housed in the tapered hole, and annular groove also is equipped with jump ring 8, and jump ring 8 and steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com