Double-track eccentric structure polishing machine

An eccentric structure and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of motor service life impact, singleness, and laborious use, and reduce professionalism , increase functions, improve the effect of polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

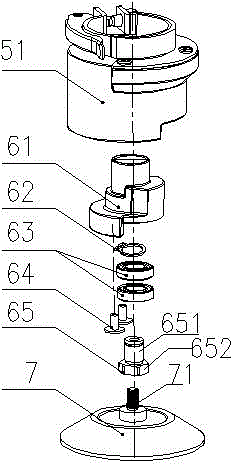

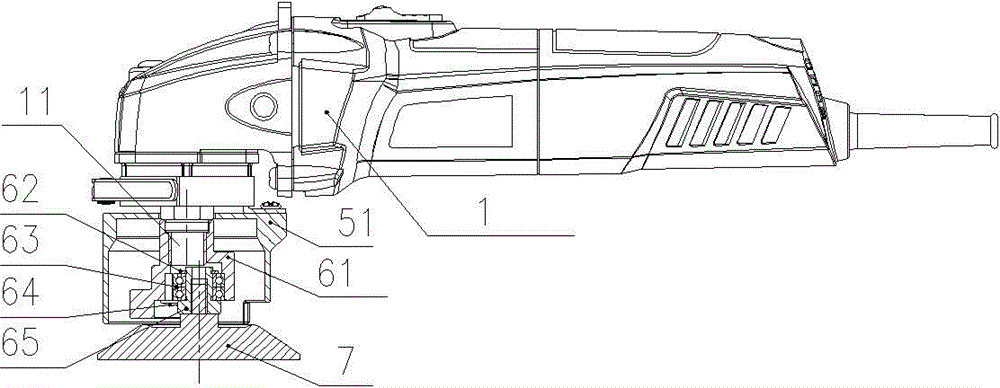

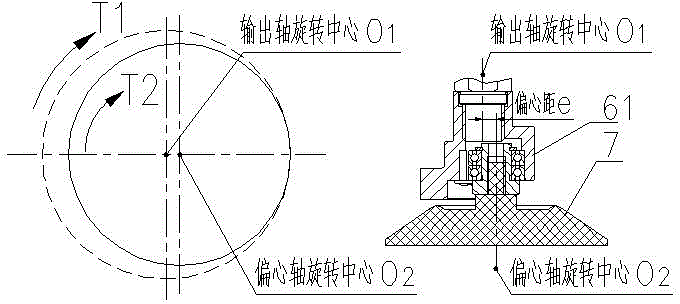

[0022] refer to figure 1 , 2 , a double-track eccentric structure polishing machine, including a body 1, a drive motor is arranged in the body, the drive motor is connected to an output shaft 11, and it also includes a polishing cover 51, an eccentric block 61, a rolling bearing 63, an eccentric shaft 65 and a polishing disc 7. The upper part of the eccentric block 61 is provided with an upper hole matching with the output shaft 11, and the lower part of the eccentric block 61 is provided with a lower hole matching with the eccentric shaft, and the upper hole and the lower hole are not concentric; the eccentric shaft includes a shaft body 651 and Lower end 652, the diameter of lower end 652 is greater than the shaft body 651 diameter, the rolling bearing inner ring is installed on the shaft body, the shaft upper end is equipped with a shaft circlip 62, and the rolling bearing outer ring is fixed on the eccentric block 61 by screws 64.

[0023] The upper end of the polishing d...

Embodiment 2

[0032] refer to Figure 4 , remove the polishing cover 51, eccentric block 61, rolling bearing 63, eccentric shaft 65 and polishing disc 7 of the first embodiment, and install the angle grinding assembly on the body 1 to obtain the angle grinder.

[0033] An angle grinder, comprising a body 1, the body 1 is provided with a drive motor, the drive motor is connected to an output shaft 11, and the angle grinder assembly includes a grinding wheel cover 52, an upper platen 2, a grinding wheel 3, a lower The pressure plate 4, the grinding wheel cover 52 is clamped with the machine body 1, the center of the upper pressure plate 2 and the grinding wheel sheet 3 are respectively provided with a through hole, the diameter of the through hole is not less than the diameter of the output shaft, the lower pressure plate 4 has a threaded inner hole, and the output shaft 11 Have external thread, threaded connection between the lower pressing plate 4 and the output shaft.

[0034] The assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com