Preparation method of expansion rate-controllable steel pipe and steel-slag concrete column

A technology of steel slag concrete and expansion rate, which is applied in the field of civil engineering, can solve the problems of increasing construction cost and difficulty, difficulty in achieving the best effect, complicated concrete hardening and hydration process, etc., so as to reduce project cost and construction difficulty, and improve The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific examples of steel pipe steel slag concrete columns.

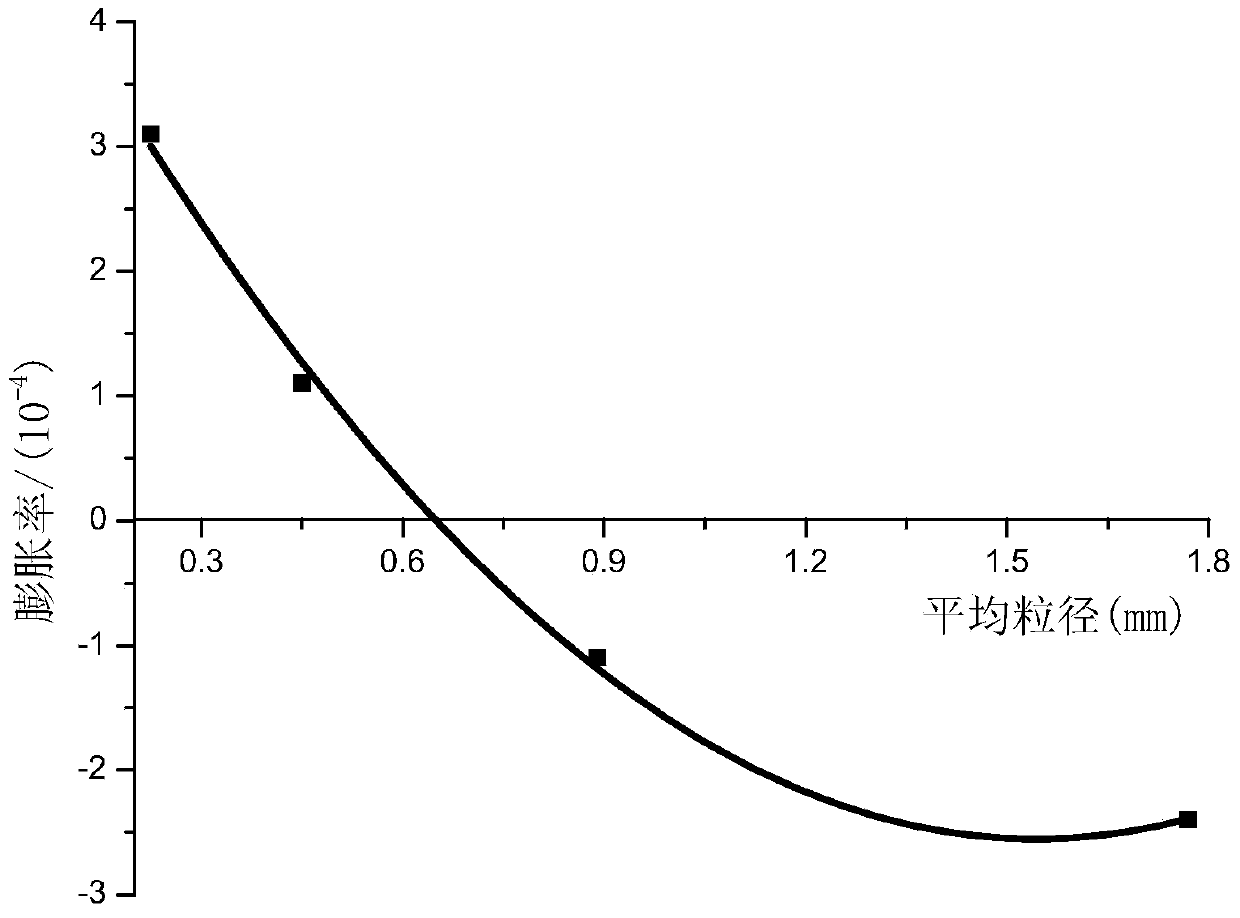

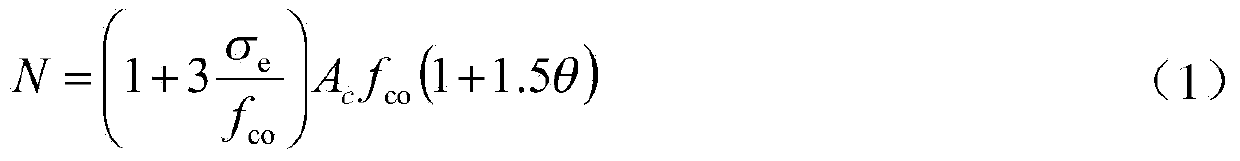

[0032] Steel slag is a kind of industrial waste, and the present invention selects steel slag to be steel slag of Masteel, adopts X-ray fluorescence spectrum analysis (XRF) to record the chemical composition of steel slag as shown in table 1, as can be seen from table 1, the chemical composition of steel slag and Similar to cement, it has a certain hydraulic activity, and the main mineral phase includes C 3 S, C 2 S, RO, C 2 F, is the main factor for the expansion of steel slag concrete in the steel pipe. In the present invention, steel slag sand is used to replace all fine aggregates, and the potential activity of steel slag sand is used to fully expand the free CaO contained in steel slag during the later hydration reaction process, so that the core concrete can enter the three-dimensional compression state in advance. The parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com