Clinker-free high-performance low-cost novel composite cementing material

A composite cementitious material, high-performance technology, applied in the direction of cement production, to achieve the effect of overcoming high energy consumption, good mechanical performance index, and good mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

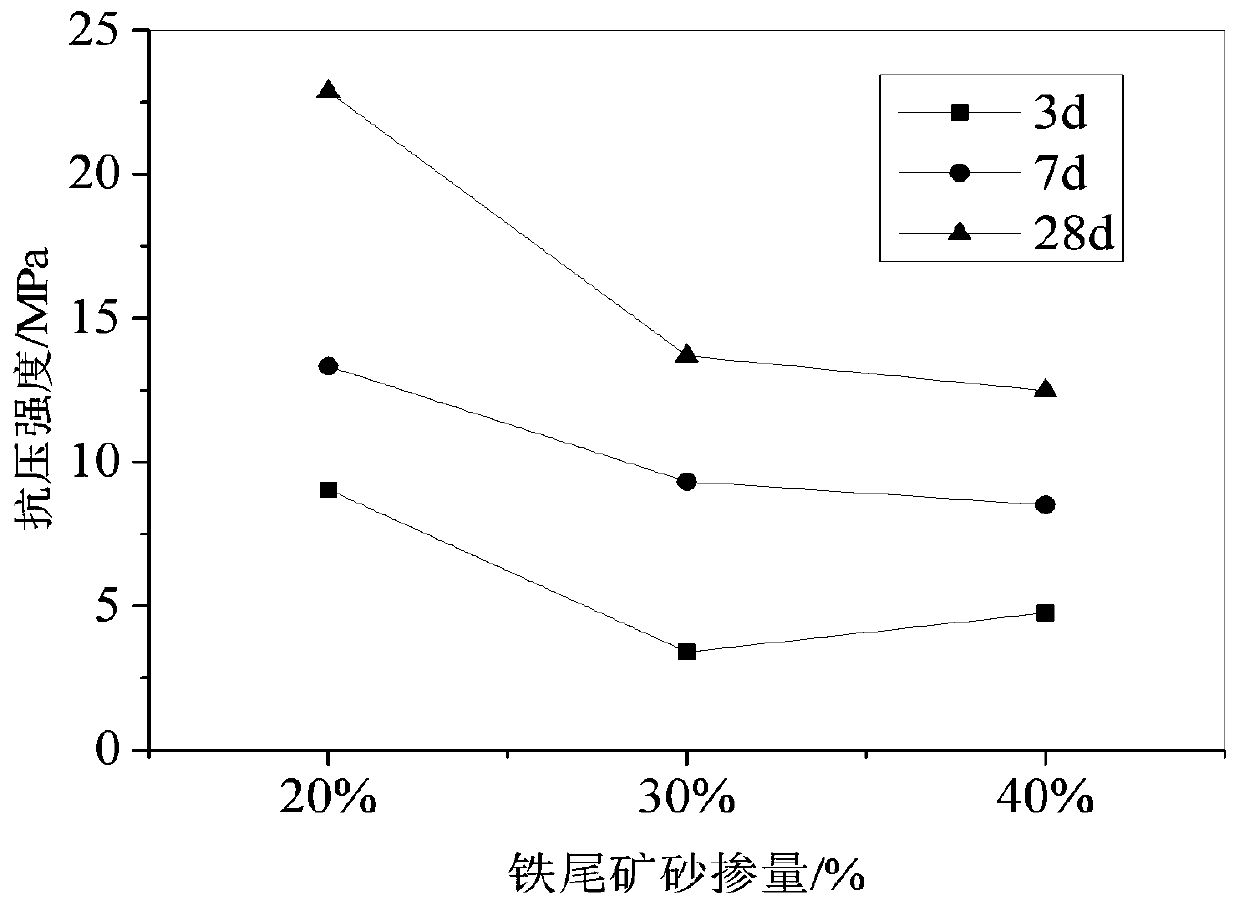

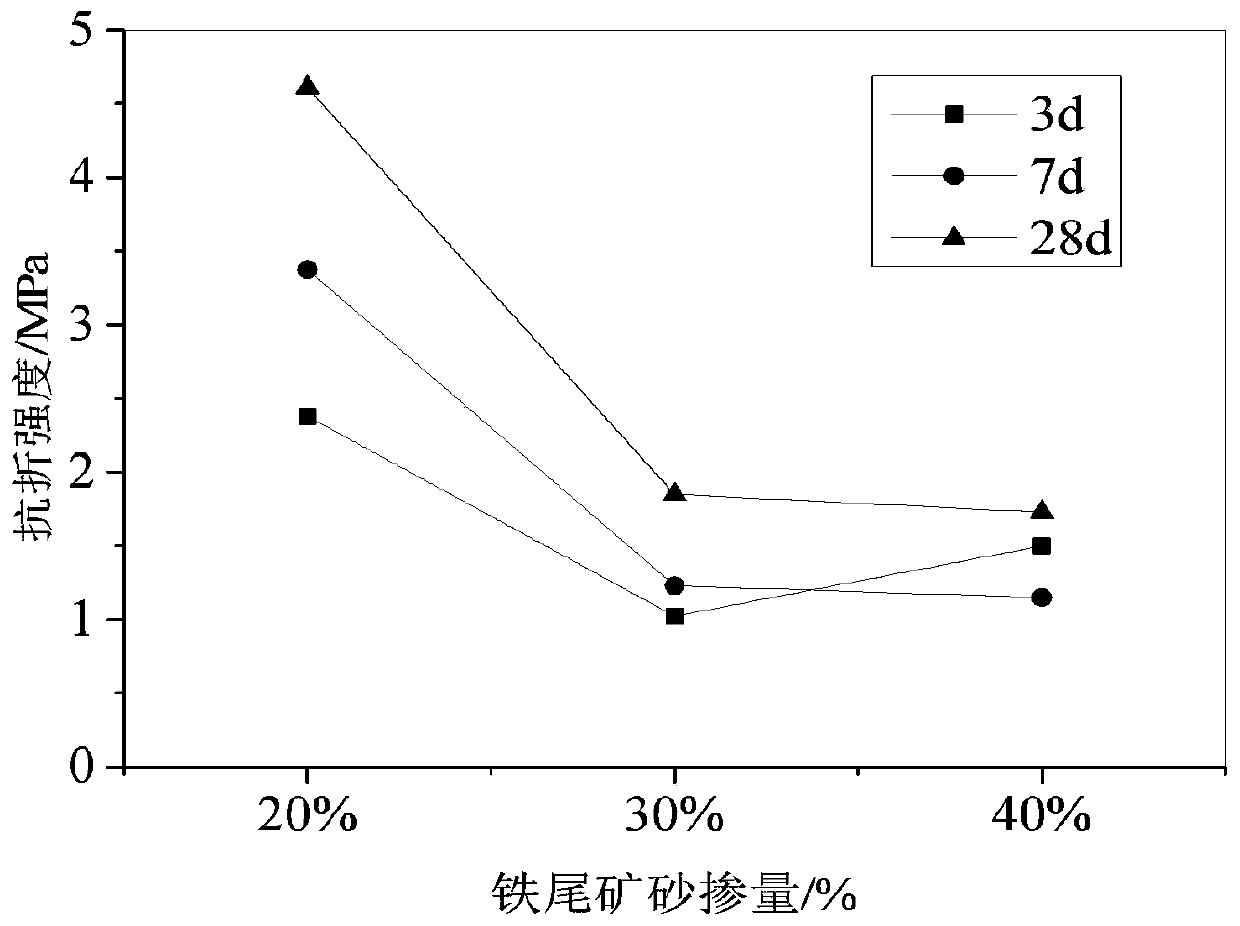

[0030] (1) A new composite cementitious material with no clinker, high performance and low cost raw materials consists of: 30% iron tailings, 45% slag micropowder, 13% quicklime, 10% desulfurized ash, 2% sodium carbonate;

[0031] (2) Weigh the raw materials according to the mass percentage in step (1), mix them evenly, add tap water according to the water-cement ratio of 0.5, stir in the mortar mixer for 90 seconds, and obtain the clinker-free New composite cementitious materials with high performance and low cost;

[0032] (3) According to the national standard GB / T17671-1999 cement mortar strength test method (IOS method), the new composite cementitious material without clinker high performance and low cost made in the step (2) is carried out strength test, test result The compressive strengths of 3d, 7d, and 28d are 3.4MPa, 9.23MPa, and 13.69MPa respectively; the flexural strengths of 3d, 7d, and 28d are 1.02MPa, 1.23MPa, and 1.85MPa.

Embodiment 2

[0034] (1) A new composite cementitious material with no clinker, high performance and low cost raw materials consists of: 40% iron tailings, 35% slag powder, 14% quicklime, 10% desulfurized ash, 1% sodium carbonate;

[0035] (2) Weigh the raw materials according to the mass percentage in step (1), mix them evenly, add tap water according to the water-cement ratio of 0.5, stir in the mortar mixer for 90 seconds, and obtain the clinker-free New composite cementitious materials with high performance and low cost;

[0036] (3) According to the national standard GB / T17671-1999 cement mortar strength test method (IOS method), the new composite cementitious material without clinker high performance and low cost made in the step (2) is carried out strength test, test result The compressive strengths of 3d, 7d, and 28d are 4.76MPa, 8.51MPa, and 12.48MPa respectively; the flexural strengths of 3d, 7d, and 28d are 1.50MPa, 1.15MPa, and 1.73MPa.

Embodiment 3

[0038] (1) The raw material of a novel composite cementitious material with no clinker, high performance and low cost consists of: 20% iron tailings, 55% slag powder, 14% quicklime, 10% desulfurized ash, 1% sodium silicate;

[0039] (2) Weigh the raw materials according to the mass percentage in step (1), mix them evenly, add tap water according to the water-cement ratio of 0.5, stir in the mortar mixer for 90 seconds, and obtain the clinker-free New composite cementitious materials with high performance and low cost;

[0040] (3) According to the national standard GB / T17671-1999 cement mortar strength test method (IOS method), the new composite cementitious material without clinker high performance and low cost made in the step (2) is carried out strength test, test result The compressive strengths of 3d, 7d, and 28d are 9.04MPa, 13.33MPa, and 22.86MPa respectively; the flexural strengths of 3d, 7d, and 28d are 2.38MPa, 3.37MPa, and 4.61MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com