Device and equipment for continuous production ofalkaline ferrate, especially of sodium ferrate

A technology for producing sodium ferrate and ferrate, which is applied in the direction of cells, electrolysis process, diaphragm, etc., can solve the problem of low ion migration and achieve the effect of low consumption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

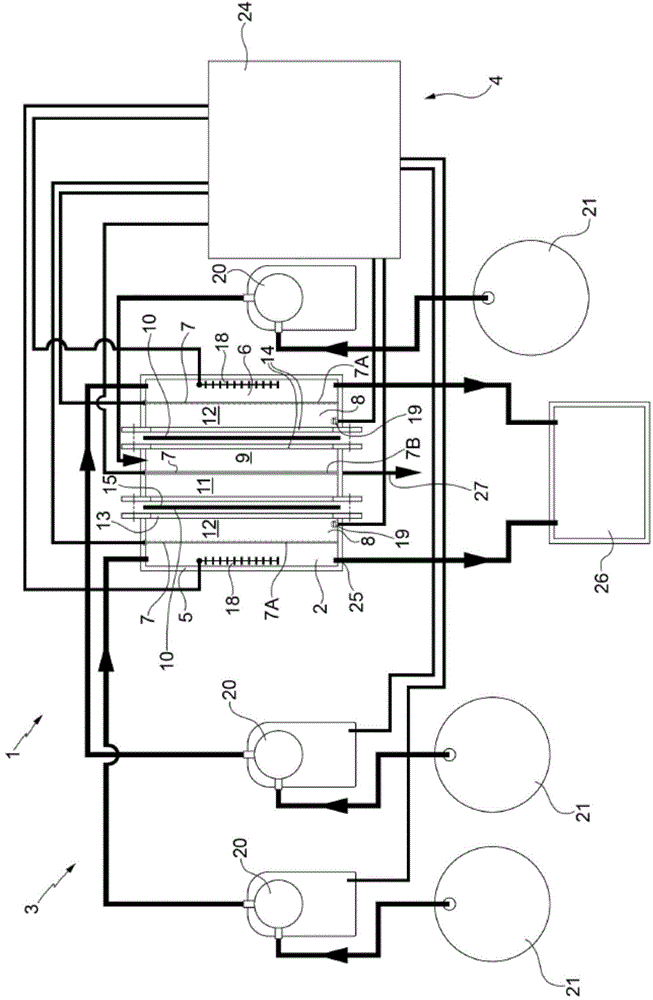

[0027] The accompanying drawing is a schematic diagram of a plant 1 for the production of alkaline ferrate, specifically sodium ferrate.

[0028] The plant 1 comprises an electrolytic cell 2 , a circulation system 3 and a power supply and control system 4 .

[0029] The cell 2 comprises an outer shell structure 5 made of an alkali-resistant polymeric material, such as polypropylene, and defines an internal reaction tank 6 provided with electrodes 7 .

[0030] The reaction cell 6 is divided into at least one anode compartment 8 provided with at least one anode 7A and containing an anolyte (liquid solution), and at least one cathode compartment 9 provided with at least one cathode 7B and containing a catholyte (liquid solution); The cathode compartment 9 is separated from the anode compartment 8 by at least one conductive membrane 10 .

[0031] In the advantageous embodiment described, the reaction tank 6 is divided into three chambers which are open at the top and arranged lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com