A washing machine with closed and isolated structure of inner and outer tubs

A technology of isolation structure and inner and outer barrels, applied in the field of washing machines, can solve problems such as unsanitary and inconvenient living, and achieve the effects of saving water, reasonable structure and preventing the spread of infectious diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

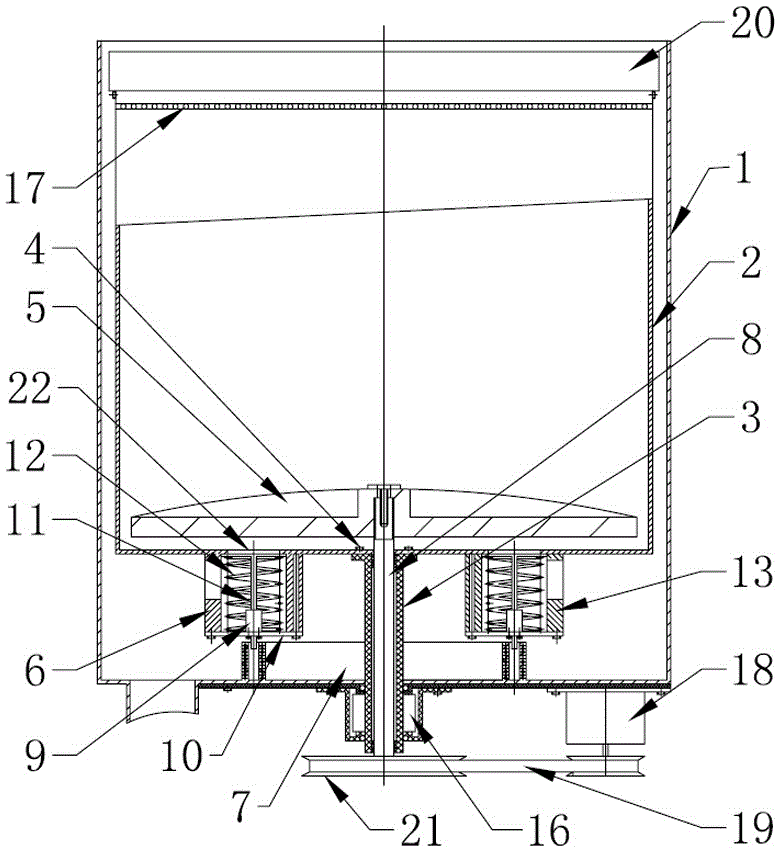

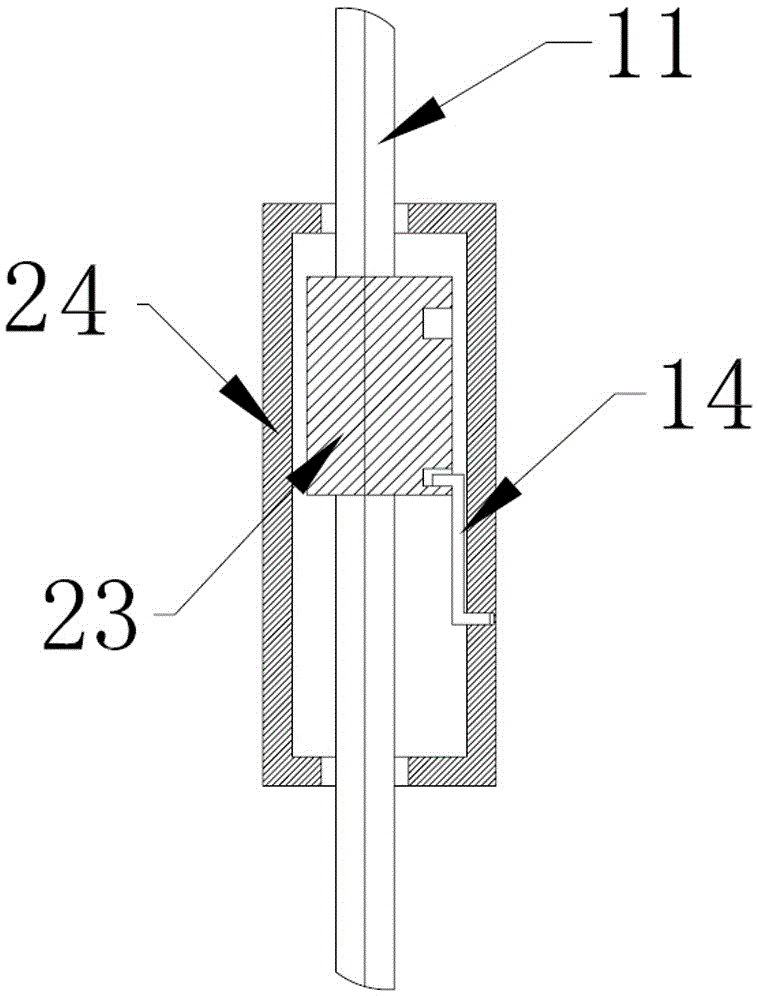

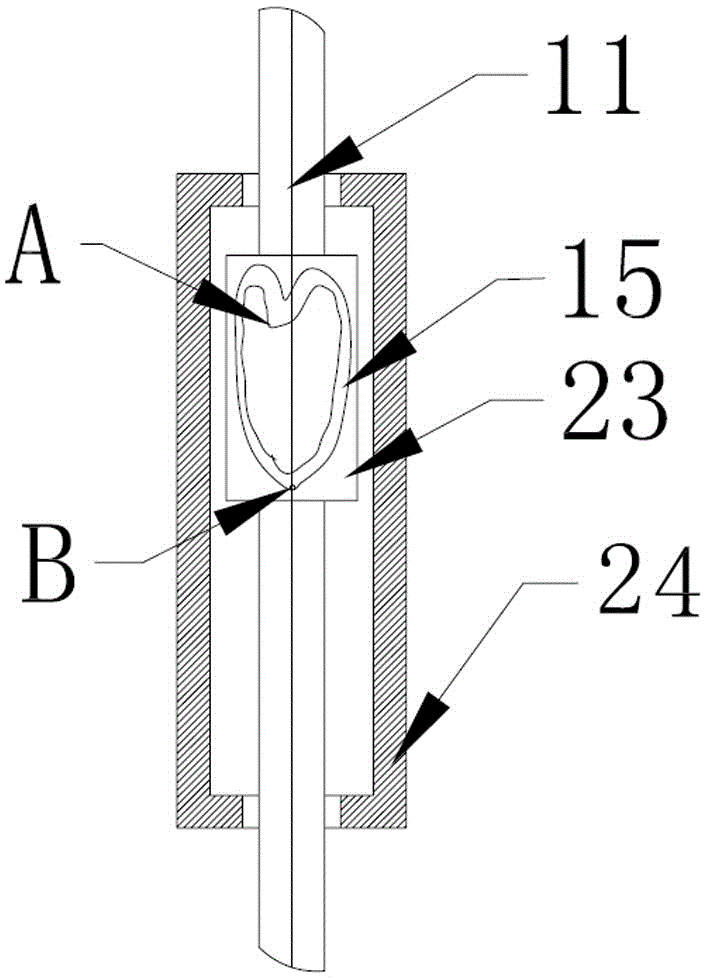

[0018] according to figure 1 , figure 2 , image 3 As shown, the present invention has an outer barrel 1, an inner barrel 2, a pulsator 5, a drainage control valve 13, a clutch coil 7, a mechanical self-locking mechanism 9, a motor 18, a belt 19, a pulley 21, a balance ring 20, a pulsator shaft 8, and a dehydration shaft 3. On the basis of the clutch 16, its characteristic is that the bottom of the inner barrel 2 is connected with the top of the dehydration shaft 3 and tightened by the inner barrel screw 4; a clutch coil 7 is arranged in the middle of the bottom of the outer barrel 1, and the clutch coil 7 is ring-shaped A magnetic suction groove is provided; a row of dehydration anti-overflow holes 17 is arranged below the balance ring 20 on the barrel body of the inner barrel 2; a drain is provided at the bottom of the inner barrel 2, and a drain control valve 13 is installed on the drain. The spool 11 of 13 extends vertically downwards into the magnetic attraction groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com