A mine wet dust collector

A wet dust collector and mining technology, applied in the fields of dust prevention, mining equipment, use of liquid separators, etc., can solve the problems of poor water flow of fans, easy blockage of filters, poor dust removal efficiency, etc., and achieve stable and reliable working conditions. Compact, low maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

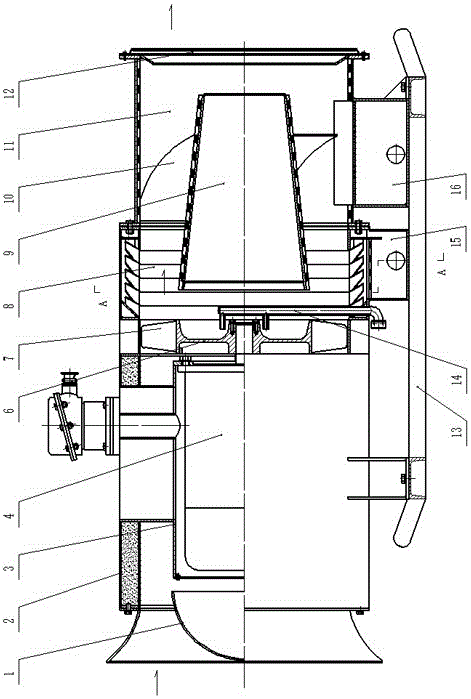

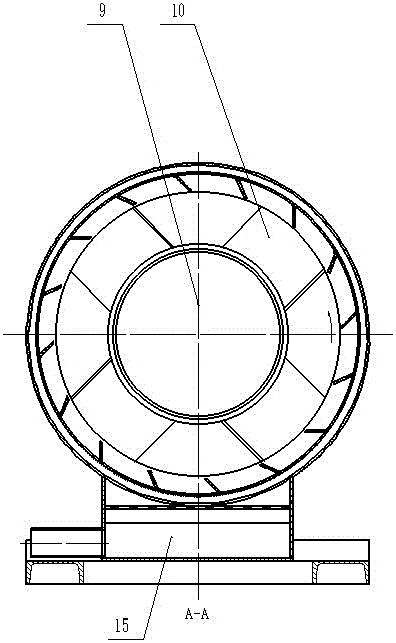

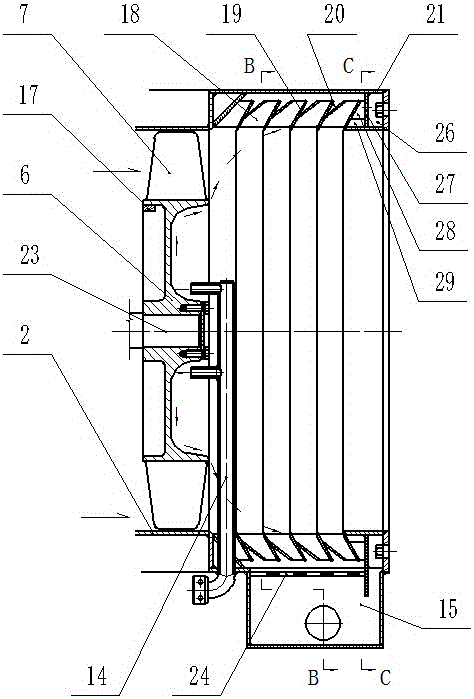

[0022] Below in conjunction with accompanying drawing, further illustrate the present invention.

[0023] exist Figure 1-2 Among them, the mining wet dust collector of the present invention is mainly composed of an axial flow fan 2, a water supply pipe 14, a water collection cylinder 8, a dehydration cylinder 11 and a frame 13. The axial fan 2 is located at the front of the mine wet dust collector, and is fastened on the frame 13 with bolts. The water receiving cylinder 8 is welded on the outer casing of the axial flow fan 2 , and the water supply pipe 14 is welded on the outer casing of the water collecting cylinder 8 and passes into the water collecting cylinder 8 inside. The dehydration cylinder 11 is fastened on the flange of the water receiving cylinder 8 with bolts, and is connected with the frame 13 with bolts.

[0024] In the axial flow fan 2, the air collector 1 is fastened to the front end of the casing of the axial flow fan 2 with bolts, the fan motor 4 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com