Harmless and resourceful treatment system and process for activated sludge

A treatment system and activated sludge technology, applied in sludge treatment, electrochemical sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of sensible heat loss in heat treatment methods, increasingly stringent dehydration rate requirements, Process energy consumption dispersion and other issues to achieve the effect of improving the utilization rate of electric energy-heat energy, ensuring the utilization rate of carbon source resources, and reducing heat exchange recovery equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

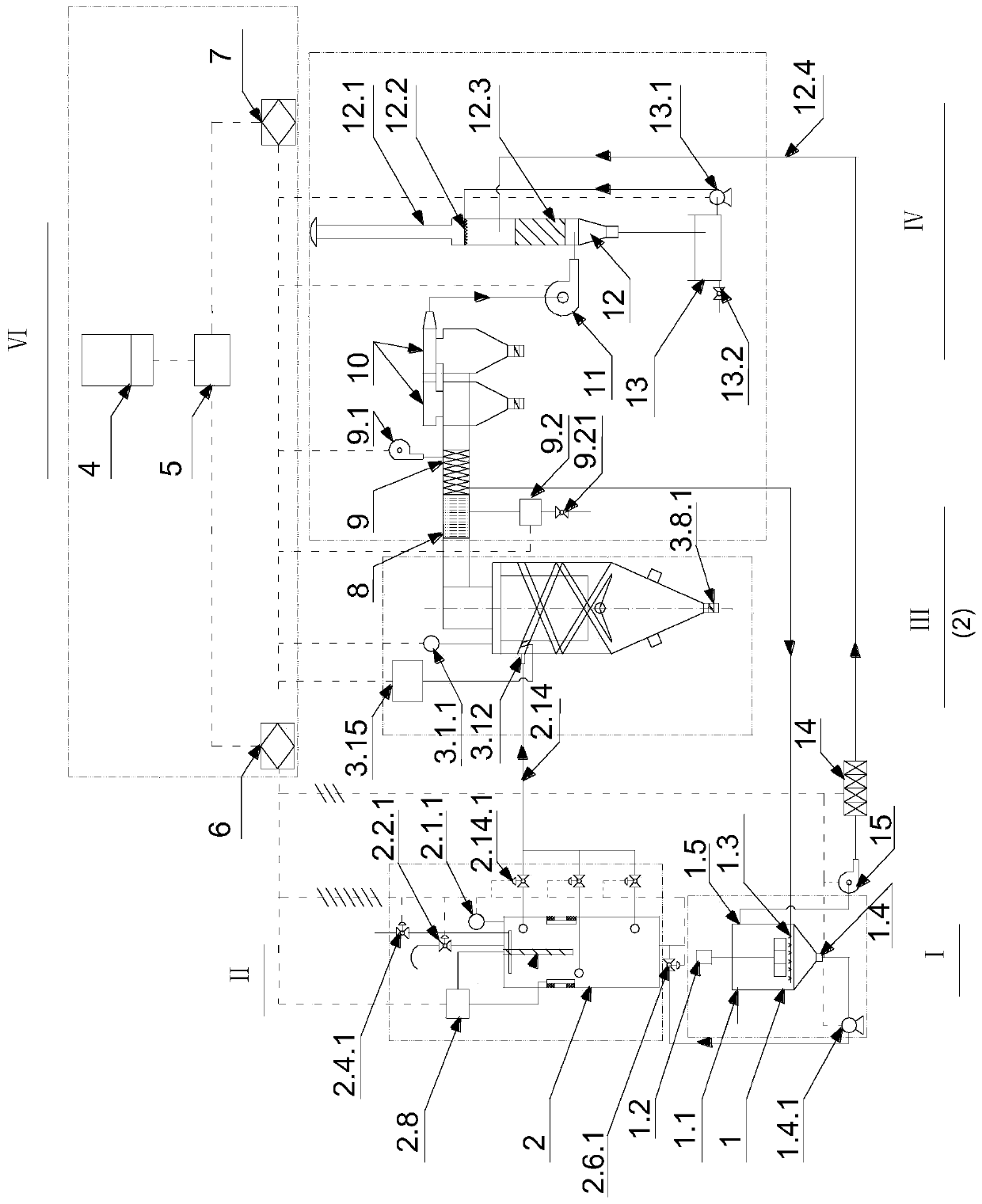

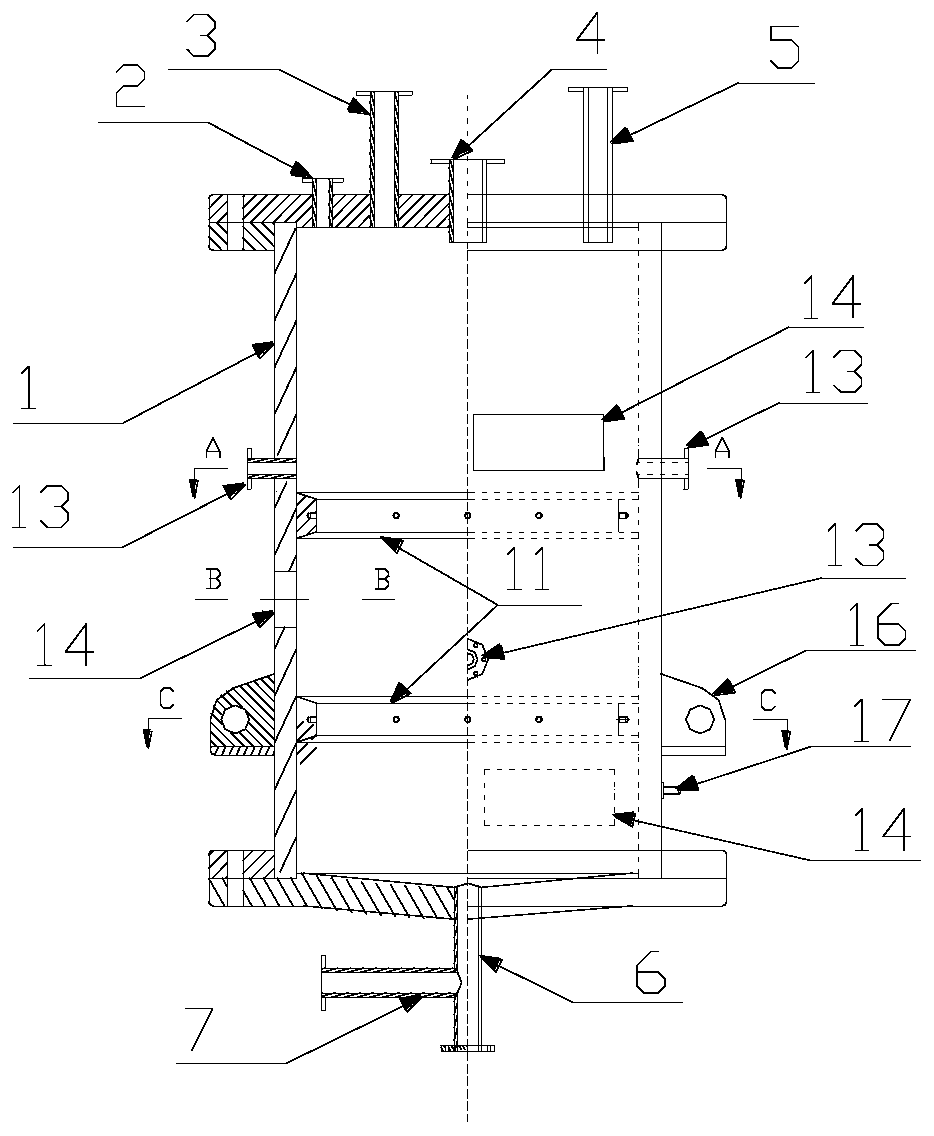

[0066] like Figure 1-24 A harmless and resourceful treatment system for activated sludge is shown, which includes four treatment stages, namely raw material pretreatment section I, electrolytic pretreatment section II, cracking and centrifugal separation section III, waste heat recovery and tail gas treatment Section IV and exhaust automatic control section V;

[0067] The raw material pretreatment section I includes a raw material ripening device 1, which is provided with a deceleration agitator 1.2, and an air distributor 1.3 is arranged under the stirring blade of the deceleration agitator 1.2; The feed pipe 1.1, the raw material aging outlet 1.4 and the gas outlet 1.5 are provided on the bottom and the side wall of the raw material aging device 1 respectively;

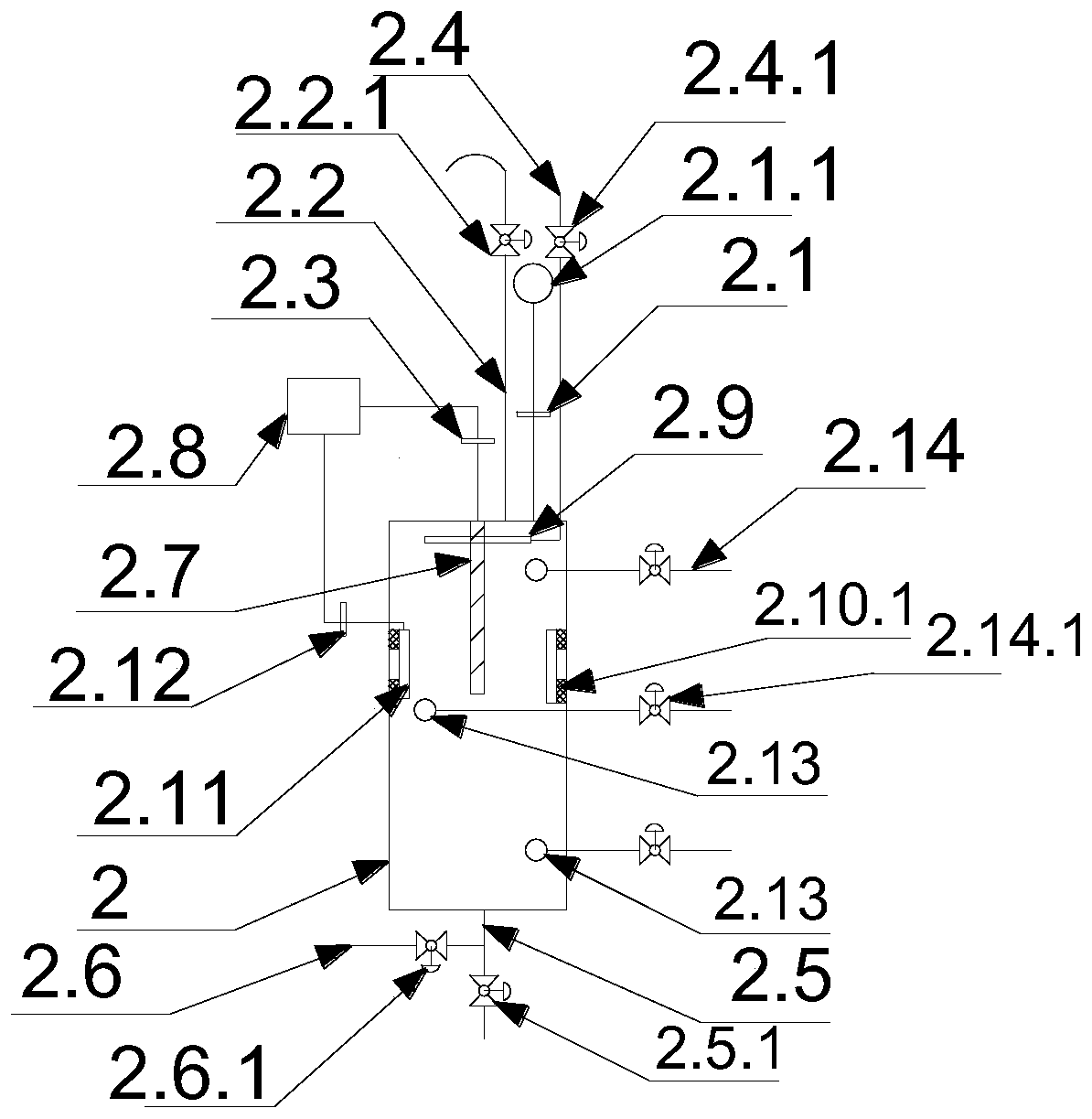

[0068] The electrolytic pretreatment section II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com