Method for in-situ deep dehydration treatment in urban sludge plants

A deep dewatering and sludge plant technology, applied in water/sludge/sewage treatment, sludge treatment, sludge detoxification, etc., can solve the problems of wasting manpower, material resources and capital, complicated process and unsatisfactory effect, etc. Achieve the effect of saving investment, fast settling speed, and improving dehydration and concentration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

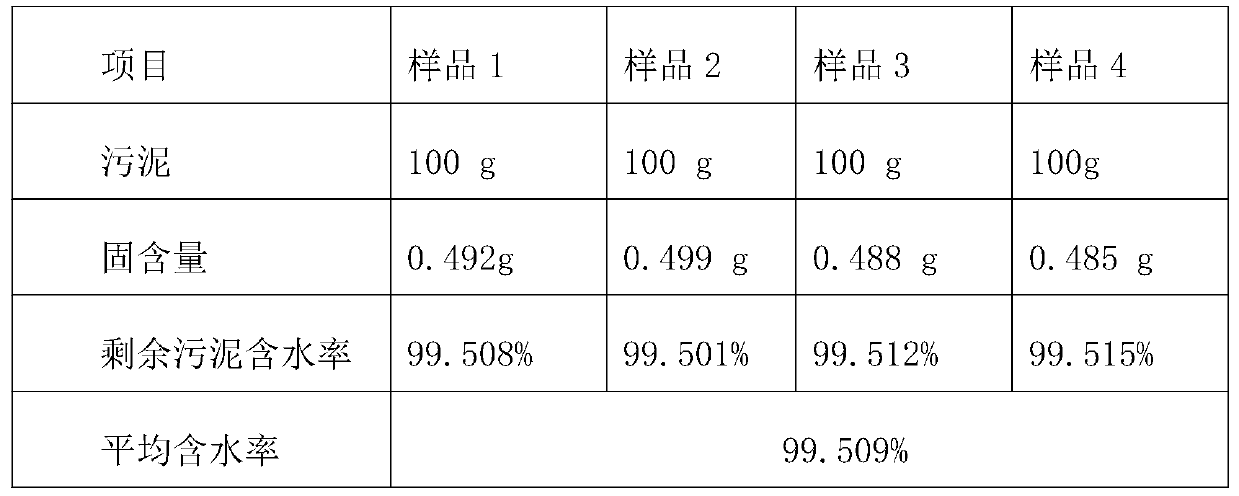

Embodiment 1

[0036] Take 1.5kg of the sludge to be tested and put it in a beaker, add a mixture of polyaluminum chloride and weak cationic polyacrylamide with a mass ratio of 1:1; the amount of the mixture of polyaluminum chloride and weak cationic polyacrylamide is 30g , the concentration of polyaluminum chloride is 0.08g / L, and the ionicity of weak cationic polyacrylamide is 20%.

[0037] The mixed solution is introduced into a gravity concentration device, and naturally settled, and after 15 minutes, supernatant and concentrated sludge are obtained. Continue to add 0.3g of potassium persulfate to the gravity concentration device and mix with the concentrated sludge. After reacting for 30-60 minutes, add 0.015g of quicklime in the gravity concentration tank and stir thoroughly; then filter through a vacuum filter to achieve solid-liquid purpose of separation.

Embodiment 2

[0039] Take 1.5kg of the sludge to be tested and place it in a beaker, add a mixture of polyaluminum chloride and weak cationic polyacrylamide with a mass ratio of 1:2; the amount of the mixture of polyaluminum chloride and weak cationic polyacrylamide is 30g , the concentration of polyaluminum chloride is 0.06g / L, and the ionicity of weak cationic polyacrylamide is 10%.

[0040] The mixed solution is introduced into a gravity concentration device, and naturally settled, and after 20 minutes, supernatant and concentrated sludge are obtained. Continue to add 0.15g of potassium persulfate to the gravity concentration device and mix with the concentrated sludge. After reacting for 30-60 minutes, add 0.012g of quicklime in the gravity concentration tank and stir thoroughly; then filter through a vacuum filter to achieve solid-liquid purpose of separation.

Embodiment 3

[0042] Take 1.5kg of the sludge to be tested and place it in a beaker, add a mixture of polyaluminum chloride and weak cationic polyacrylamide with a mass ratio of 1:3; the amount of the mixture of polyaluminum chloride and weak cationic polyacrylamide is 75g , the concentration of polyaluminum chloride is 0.06g / L, and the ionicity of weak cationic polyacrylamide is 10%.

[0043] The mixed solution is introduced into a gravity concentration device, and naturally settled, and after 25 minutes, supernatant and concentrated sludge are obtained. Continue to add 0.375g of potassium persulfate to the gravity concentration device and mix with the concentrated sludge. After reacting for 30-60 minutes, add 0.012g of quicklime in the gravity concentration tank and stir thoroughly; then filter through a vacuum filter to achieve solid-liquid purpose of separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com