Sand removing device applicable to high-pressure and high-yield gas well

A high-yield, gas well technology, applied in the direction of combined devices, wellbore/well components, production fluids, etc., can solve the problems of poor site adaptability, difficult management of desanding devices, high investment costs, etc., and achieve the effect of preventing erosion and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

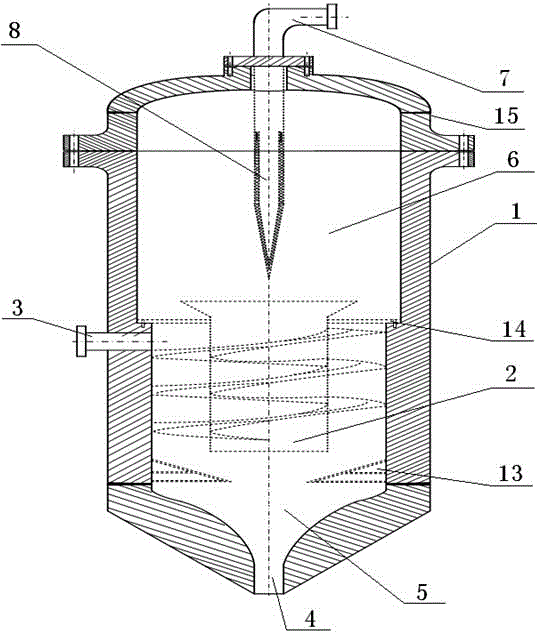

[0028] Such as figure 1 As shown in the structural diagram of the desanding device for the high-pressure and high-yield gas well, it at least includes a pressure vessel 1 in a vertical structure, a cyclone separator 2 is arranged under the pressure vessel 1, and an air inlet 3 is located on the side of the cyclone separator 2 At the side wall of the square pressure vessel 1, the bottom of the pressure vessel 1 is the sand discharge port 4, the sand storage area 5 is between the bottom of the cyclone separator 2 and the sand discharge port 4, and the inner space of the pressure vessel 1 above the cyclone separator 2 It is a gravity settling area 6 , the top of the pressure vessel 1 has an air outlet 7 , and a filter cartridge 8 is connected below the air outlet 7 , and the filter cartridge 8 extends into the gravity settling area 6 .

[0029] The gas inlet 3 is arranged at the side wall of the pressure vessel 1 along the tangential direction.

[0030] The pressure vessel 1 of ...

Embodiment 2

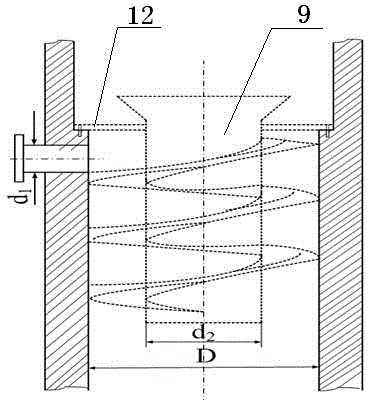

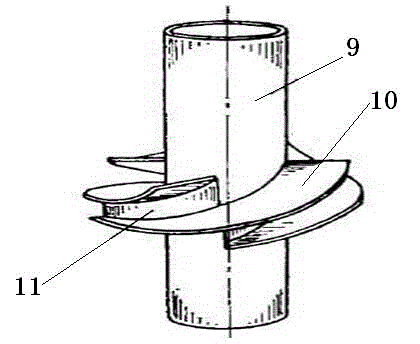

[0034] Such as figure 2 As shown in the structural schematic diagram of the cyclone separator, the cyclone separator in the pressure vessel 1 is composed of an air riser 9, a horizontal vane 10 and a vertical vane 11.

[0035] The upper part of the gas riser 9 is connected to the inner wall of the pressure vessel 1 above the air inlet 3 through a fixed partition 12, and the horizontal blades 10 are fixed in a spiral shape on the outer wall of the gas riser 9 below the fixed partition 12, and the spirally distributed horizontal blades 10 The inner diameter is fixedly connected with the riser pipe 9, and the outer diameter of two adjacent horizontal blades 10 is connected with a vertical blade 11, and the vertical blade 11 seals the space between the adjacent two horizontal blades 10 as an airtight space, see image 3 A helical channel is formed outside the air riser 9, the upper port of the helical channel is located at the air inlet 3 of the pressure vessel 1, and the lower p...

Embodiment 3

[0045] On the basis of Embodiment 2, there is a boss 14 on the inner wall above the air inlet 3 of the pressure vessel 1 in this embodiment, and the outer edge of the fixed partition 12 is detachably connected to the boss 14 by bolts, and the fixed partition 12 The inner edge is fixedly connected with the upper outer wall of the gas riser 9, and the upper port of the gas riser 9 above the fixed partition 12 is a bell mouth.

[0046] The top of the pressure vessel 1 is connected with a container upper cover 15 through a flange. The inner diameter of the container upper cover 15 is consistent with the inner diameter of the upper gravity settlement area 6 of the pressure vessel 1. The gas outlet 7 is located at the center of the container upper cover 15 .

[0047] The fixed partition 12 not only divides the pressure vessel 1 into upper and lower parts, the two parts are the cyclone separation area and the gravity sedimentation area 6, the two areas do not interfere with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com