Variable Displacement Swash Plate Compressor

A swash plate type, variable displacement technology, applied in the field of air-conditioning compressors, can solve problems such as affecting the operation of the compressor, severe friction, noise, parts damage, etc., and achieve the effects of simple assembly, collision prevention, and enhanced reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

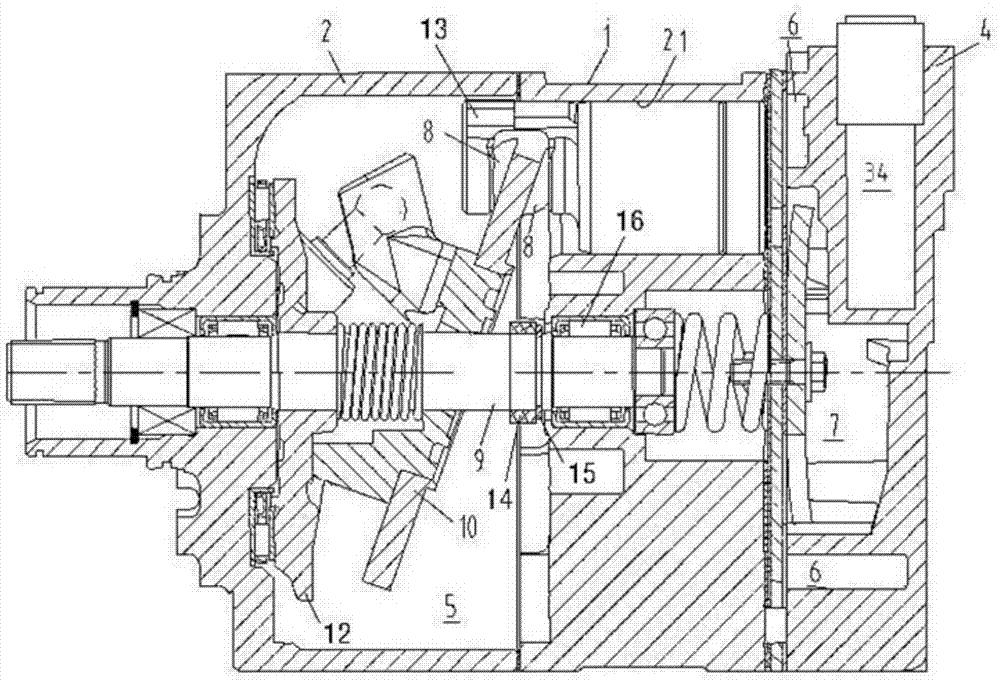

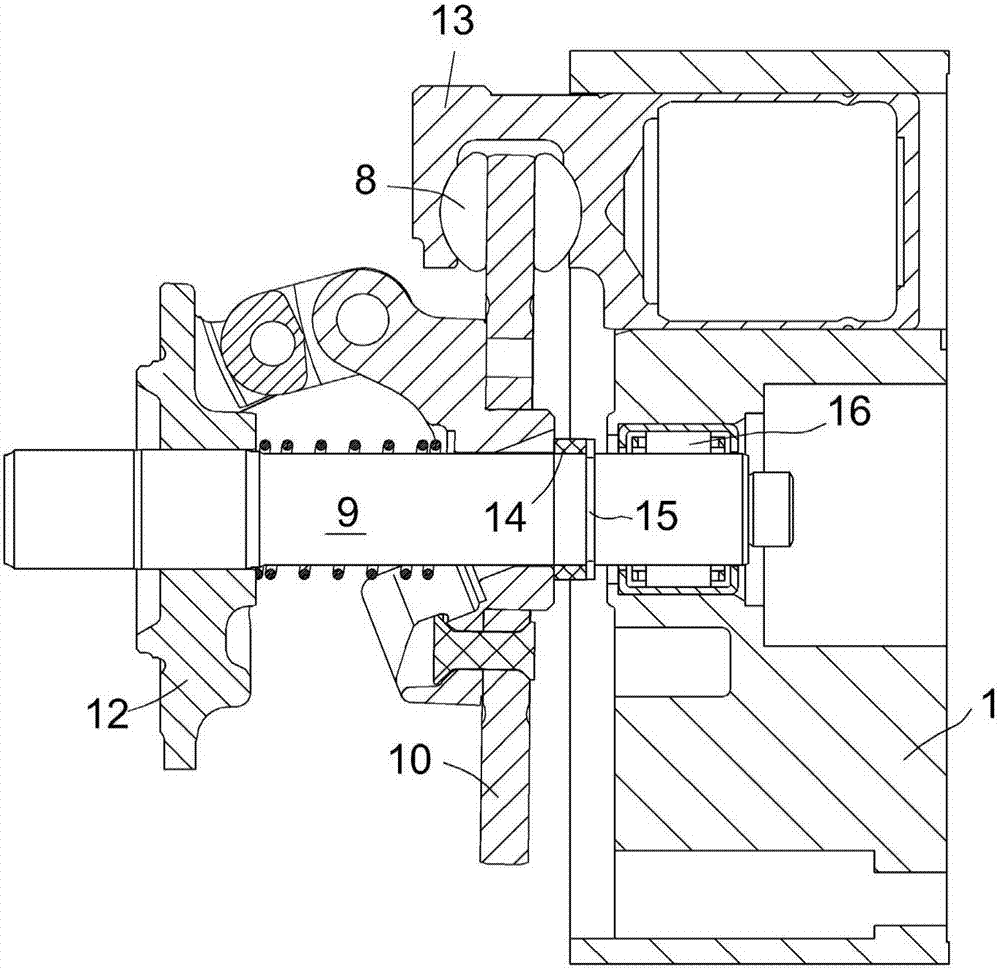

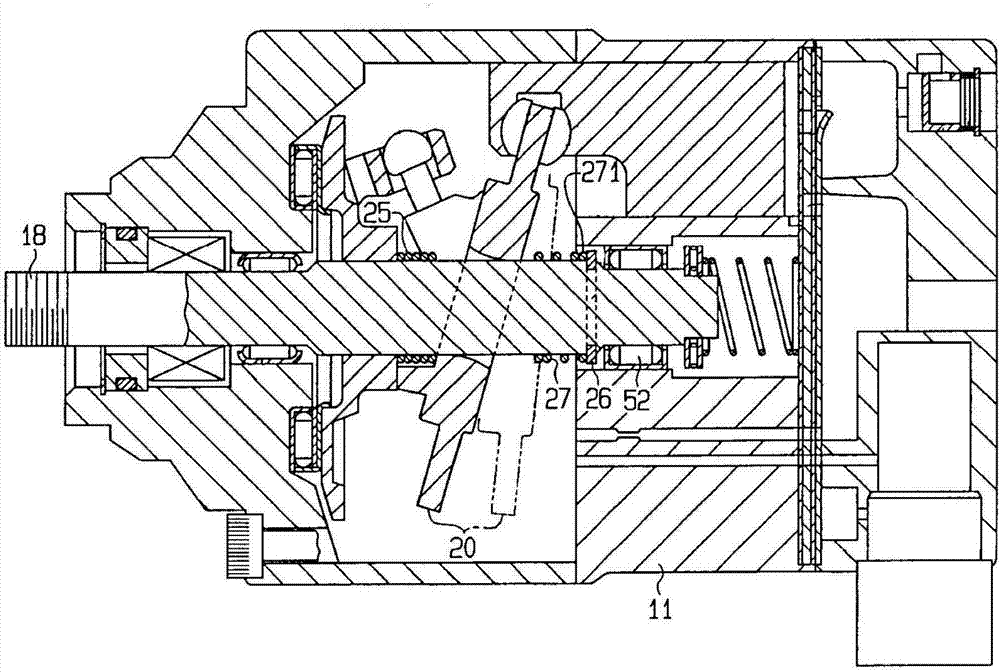

[0016] The compressor used in the refrigeration cycle of the car air conditioner is driven by the engine, and the speed of the engine changes according to the motion state of the car. The variable capacity compressor with variable refrigerant displacement can obtain sufficient cooling capacity when the engine is idling. Such as figure 1 As shown, in the variable capacity compressor, the shell of the swash plate compressor is assembled from the front cylinder head 2, the cylinder block 1 and the rear cover 4, forming the crankshaft chamber 5, the suction chamber 6, and the exhaust chamber 7 and a plurality of cylinder bores 21. When the compressor is working, the rear end of the main shaft 9 is supported by the bearing 16 in the middle hole of the cylinder body. Driven by the engine, the main shaft 9 drives the drive plate 12 mounted on it and the swash plate 10 hinged with the drive plate 12 to rotate simultaneously. The swash plate 10 forms an inclination angle with the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com