Production method of diffuser used in aerodynamic experiments

A technology of aerodynamics and manufacturing methods, applied in the design and manufacture of high temperature, manufacturing, and hypersonic aerodynamic test equipment, can solve the problems of irregular plug welding surface, unguaranteed appearance quality, deformation of inner shell, etc., to improve product quality , Improve the assembly speed, improve the effect of welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

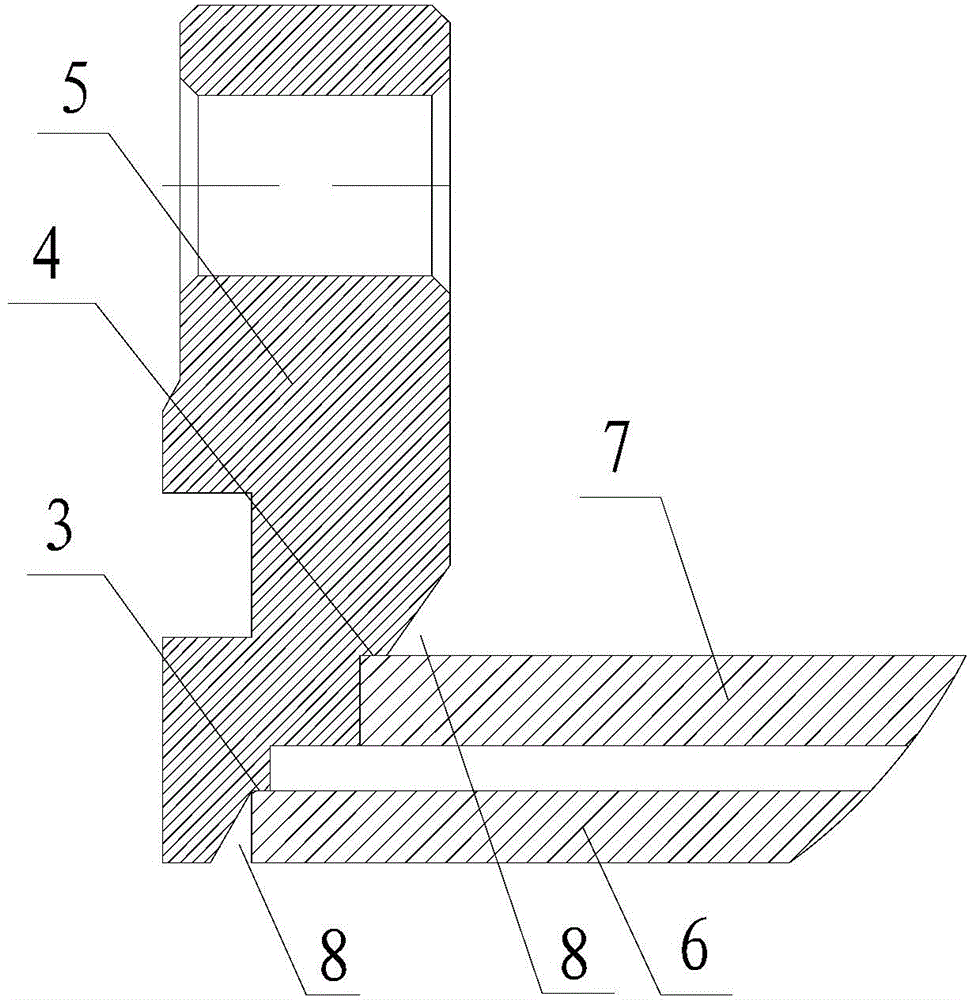

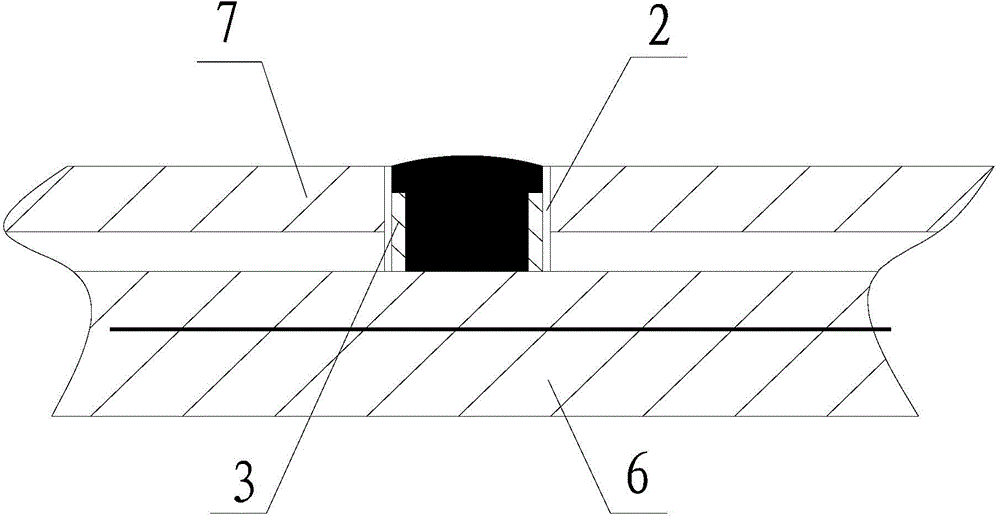

[0019] Such as figure 1 , figure 2 Shown is a method for manufacturing a diffuser for aerodynamic testing that can improve product quality and fast assembly speed provided by the present invention. The manufacturing method includes the following steps,

[0020] a. Prepare materials and make parts. First, prepare flange blanks, inner cylinder blanks, outer cylinder blanks and positioning short pipes 1 according to the drawings of the parts of the diffuser, and place them on the outer cylinder blanks. Scribe and drill the positioning hole 2; then the flange blank is processed into a flange part 5 with an inner cylinder positioning step 3 and an outer cylinder positioning step 4 for use, and the inner cylinder blank and the outer cylinder blank are respectively rolled into The inner cylinder part 6 and the outer cylinder part 7 are for use,

[0021] b. Parts production, using the inner cylinder positioning step 3 and the outer cylinder positioning step 4 on the flange part 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com