BP neutral network heavy machine tool thermal error modeling method optimized through genetic algorithm

A technology of BP neural network and genetic algorithm, which is applied in the field of BP neural network thermal error modeling of heavy-duty machine tools, achieves the effect of simple structure, good reliability and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

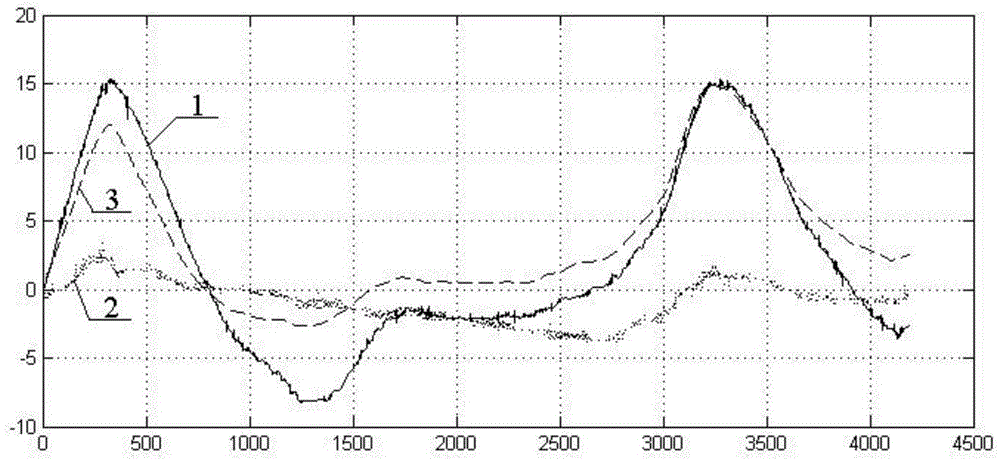

[0046] The BP neural network thermal error modeling method for heavy-duty machine tools based on genetic algorithm optimization involved in the present invention is mainly used for compensating the thermal errors generated in the machining process of heavy-duty numerical control machine tools and improving machining accuracy.

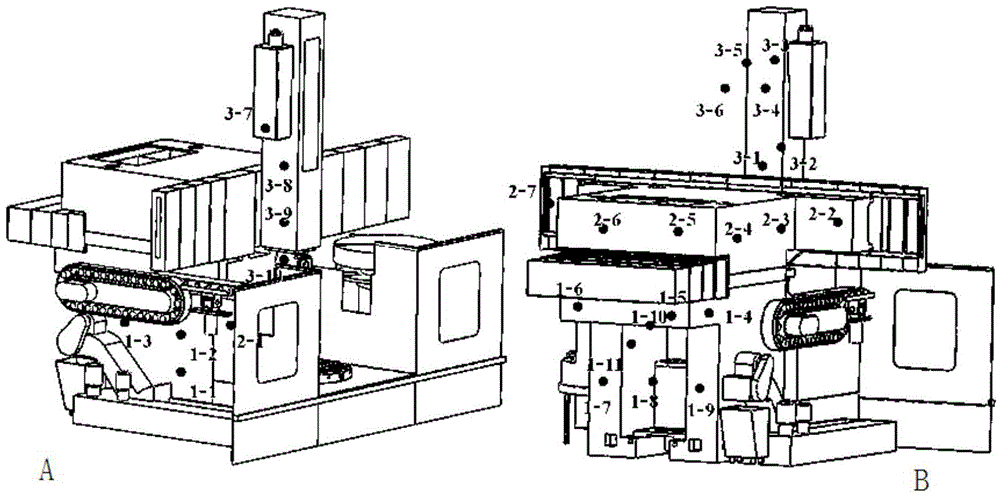

[0047] The present invention takes the CR5116 flexible vertical processing unit as the research object. The processing unit not only has the functions of the general CNC vertical processing unit, but also can complete drilling, milling, boring, tapping, grinding and other functions in one clamping, and can process Various complex surfaces.

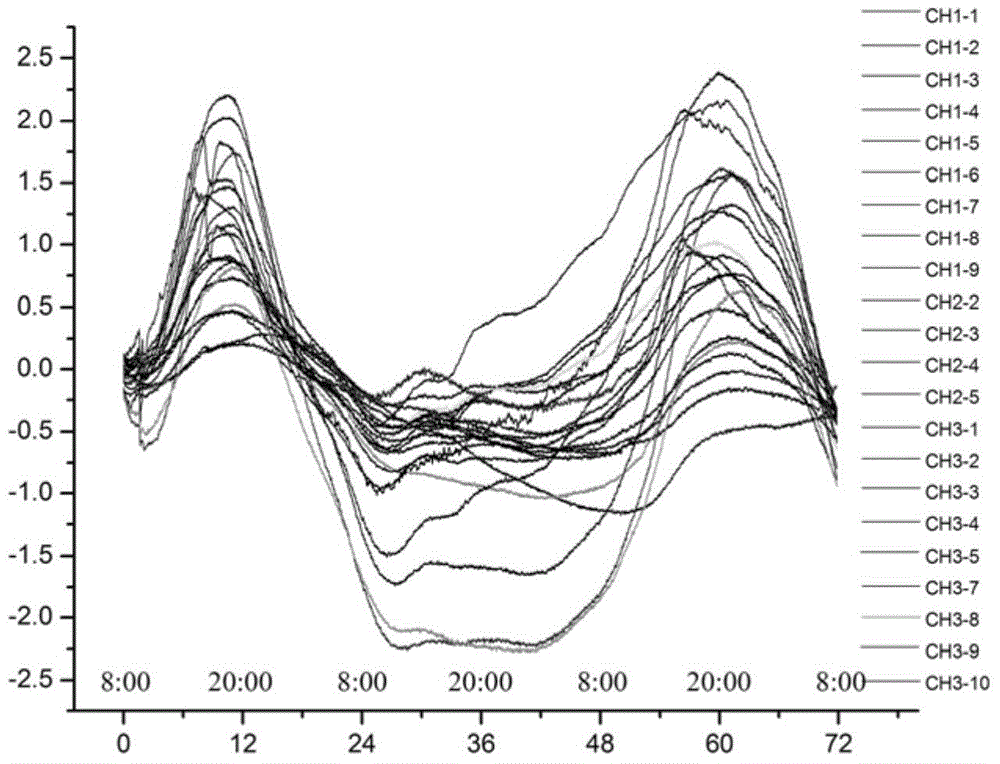

[0048] The temperature field of the heavy-duty CNC machine tool is directly affected by the distribution of heat sources. In order to reasonably arrange the temperature sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com