Process module layout method of gluing developer

A technology of process modules and layout methods, applied in the directions of comprehensive factory control, comprehensive factory control, digital control, etc., can solve the problems of complex operation, large floor space, inconvenient maintenance, etc., to achieve convenient operation, small floor space, Maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

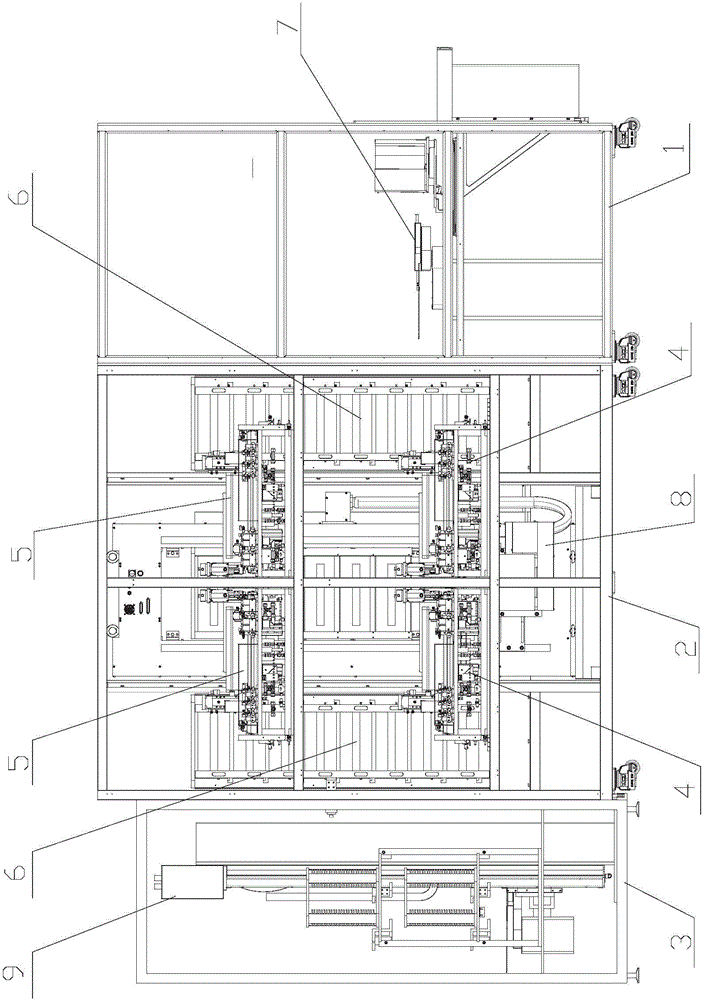

[0017] Such as Figure 1-2 As shown, the gluing and developing machine in the present invention includes a cassette station 1, a process station 2 and an interface station 3 connected in sequence, wherein the process station 2 is provided with a gluing module 4, a developing module 5, a heat treatment module 6 and a process station The robot 9, the gluing module 4 and the developing module 5 are all arranged in front of the process station 2, and the developing module 5 is located above the gluing module 4, the gluing module 4 and the developing module 5 are concentrated to form a process rotation processing center, for Wafers are glued and developed. Heat treatment modules 6 are provided on both sides and the back of the process station 2 , and the process station robot 9 is set at the center of the process station 2 . The wafer transfer between the cassette station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com