Immersed liquid cooling server and immersed liquid cooling method for server

A server and immersion technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems of insufficient cooling capacity of cooling elements, energy loss, pressure rise of refrigerant tank, etc., and achieve enhanced condensation heat transfer Effect, enhanced condensation heat transfer, enhanced heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

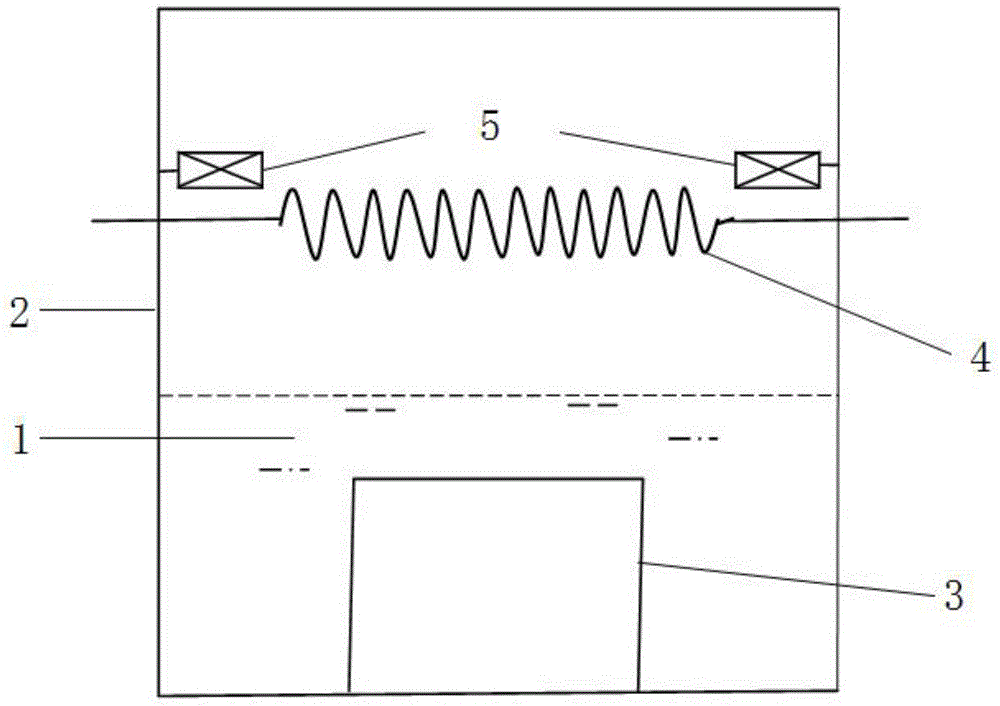

[0021] see figure 1 , an embodiment of the submerged liquid-cooled server of the present invention includes a refrigerant tank 2 , a heating element 3 disposed in the refrigerant tank 2 , and a cooling element 4 disposed in the refrigerant tank 2 . Wherein, the refrigerant tank 2 is used to accommodate the refrigerant 1 , the heating element 3 is submerged in the refrigerant 1 , and the cooling element 4 is located above the liquid surface of the refrigerant 1 . Specifically, in this embodiment, the heating element 3 is completely submerged in the refrigerant 1, that is, the amount of the refrigerant 1 accommodated in the refrigerant tank 2 allows the heating element 3 to be completely submerged in the cooling medium throughout the refrigerant cycle. In agent 1, the heat dissipation effect is further improved.

[0022] In the submerged liquid-cooled ser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com