Green dried and salted product smoking and roasting device by use of afterheat recovery

A technology for tail heat recovery and wax products, which is applied in the field of green smoked and baked equipment for tail heat recovery wax products, can solve the problems of unsatisfactory, high energy consumption, difficult to remove harmful substances, etc., achieve removal of toxic and harmful substances, broad application prospects, The effect of low energy consumption fumigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

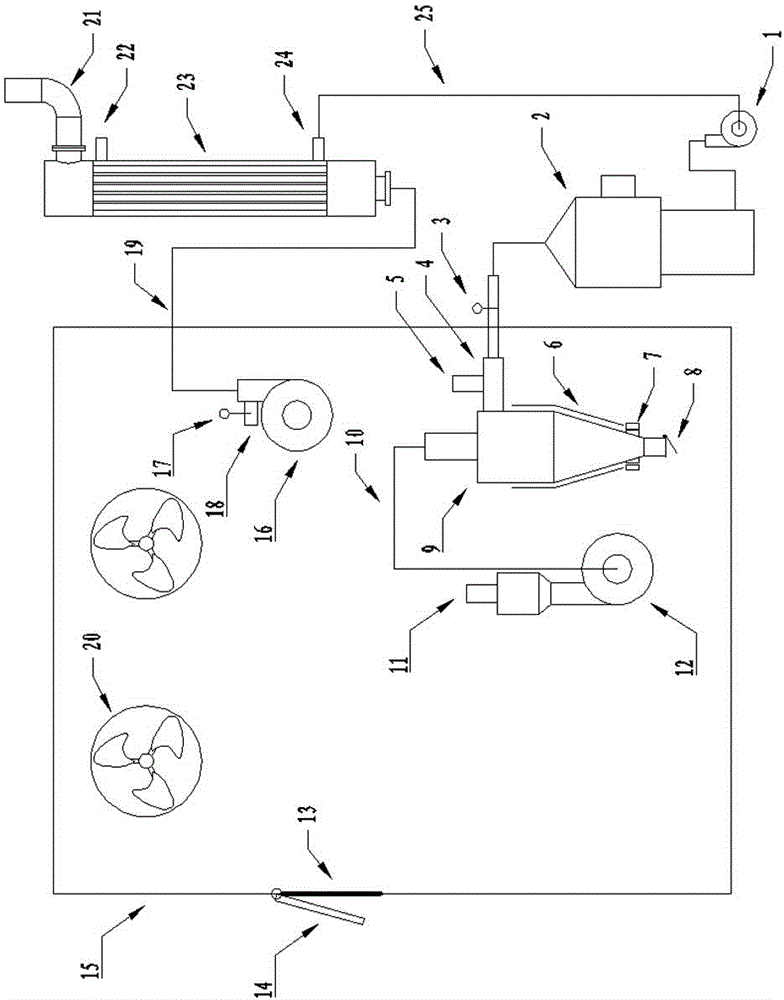

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0023] Such as figure 1 The green smoking device for tail heat recovery wax products shown includes a smoker wall 15 on which a curtain 13 and a transom 14 are arranged. The inlet pipe 4 of the device 9, the cyclone separator 9 is connected to the exhaust fan 12 through the pipeline 10, and the air outlet 11 of the exhaust fan 12 is in the wall 15; 9 The bottom is provided with a lightweight valve 8, and the surface of the cyclone separator is provided with a heat radiator 6 and a vibrator 7; a smoke exhaust fan 16 is provided in the wall 15 of the smoking room, and the return air port 18 of the smoke exhaust fan 16 is provided with a shutter 17 Adjust the air volume, the exhaust pipe 19 of the exhaust fan 16 is connected to the tube side of the tube heat exchanger 23 outside the wall 15 to realize heat recovery and then evacuated through the exhaust port 21, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com