A kind of high pressure crack initiation method in liquid at the root of surface annular groove of pipe blanking

An annular groove and internal high pressure technology, which is applied in the field of high pressure crack initiation in liquid at the root of the annular groove on the surface, can solve the problems that the blanking efficiency cannot meet the requirements of mass production and the dynamic crack propagation life is long, so as to shorten the crack propagation time and improve the The effect of blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] A liquid internal high-pressure cracking method at the root of a surface annular groove for pipe blanking, comprising the following steps:

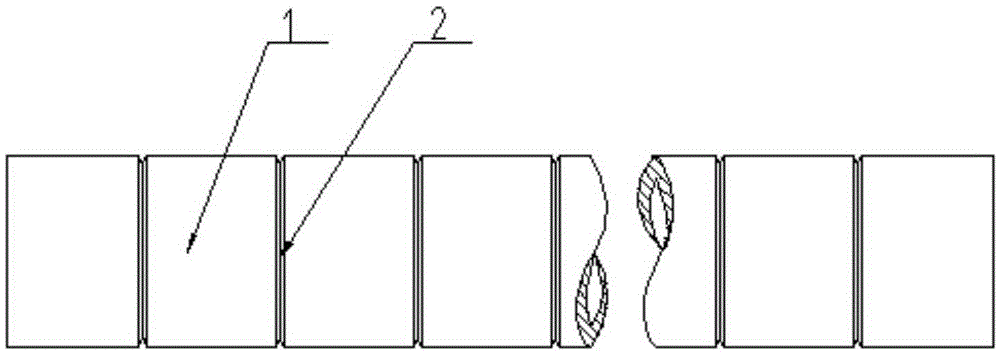

[0019] Step 1, before cracking, use a slotting machine to open an annular groove 2 on the outer surface of the metal pipe 1 according to the required blanking length;

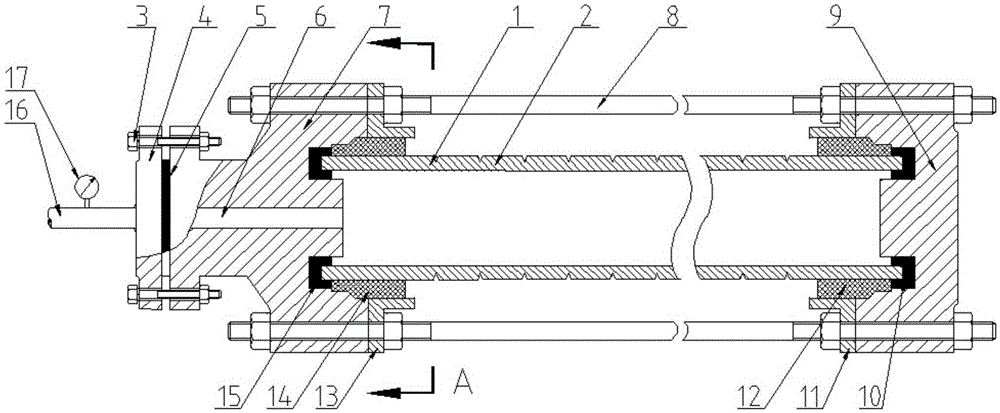

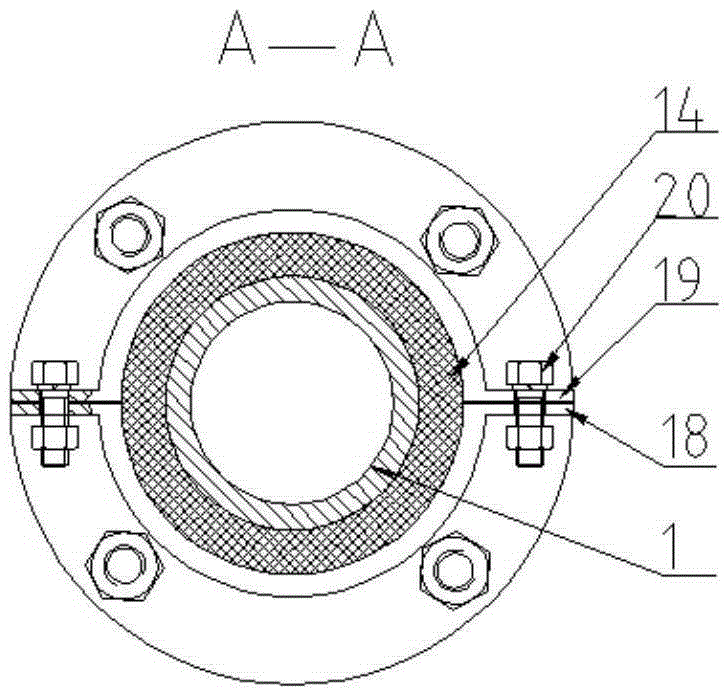

[0020] Step 2, when assembling, assemble the flange connector 7, the first clamp flange 13, the flat welding flange 4 and the liquid filling pipe 16 at one end of the metal pipe 1, and assemble the sealing head 9 and the second clamp flange at the other end 11. The two ends are respectively sealed by the first C-shaped sealing ring 15, the first stepped sealing sleeve 14, the second C-shaped sealing ring 10, and the second stepped sealing sleeve 12, and the two ends of the metal pipe 1 are connected by the first bolt 8 The flange joint 7 and the sealing h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com