Concave groove spark plug

A spark plug and concave groove technology, applied in the field of spark plugs, can solve the problems of unfavorable engine cold or low temperature start, unfavorable contact between electric spark and combustible mixture, unfavorable electric field strength formation and utilization, etc., to reduce concealment and elimination. flame effect, improved reliability and stability, reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

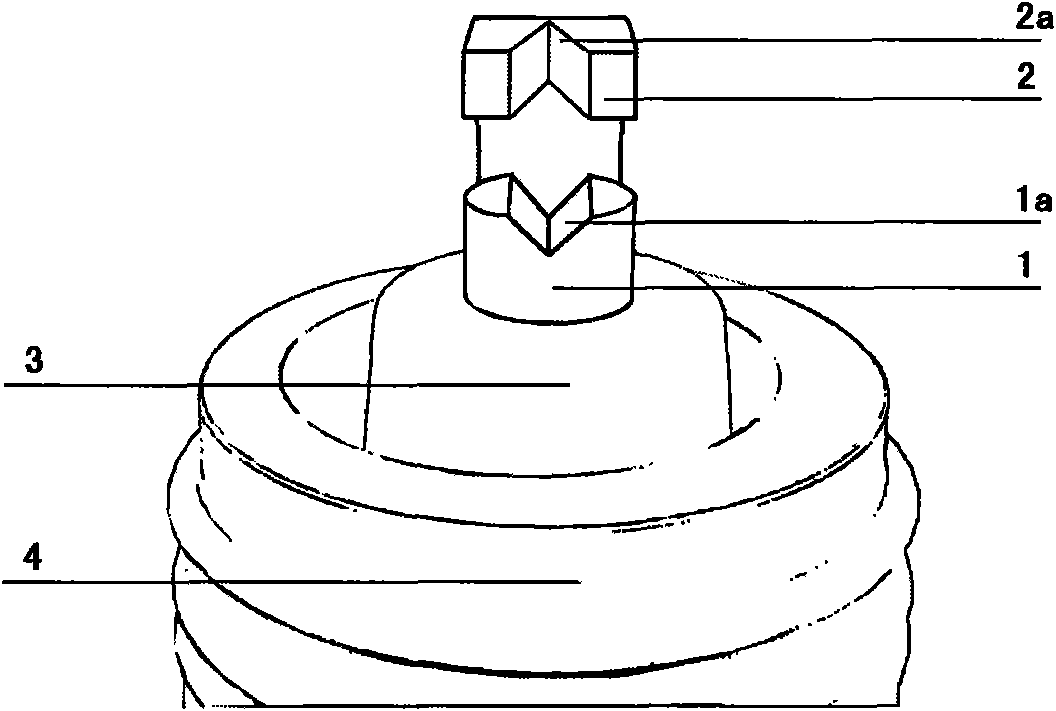

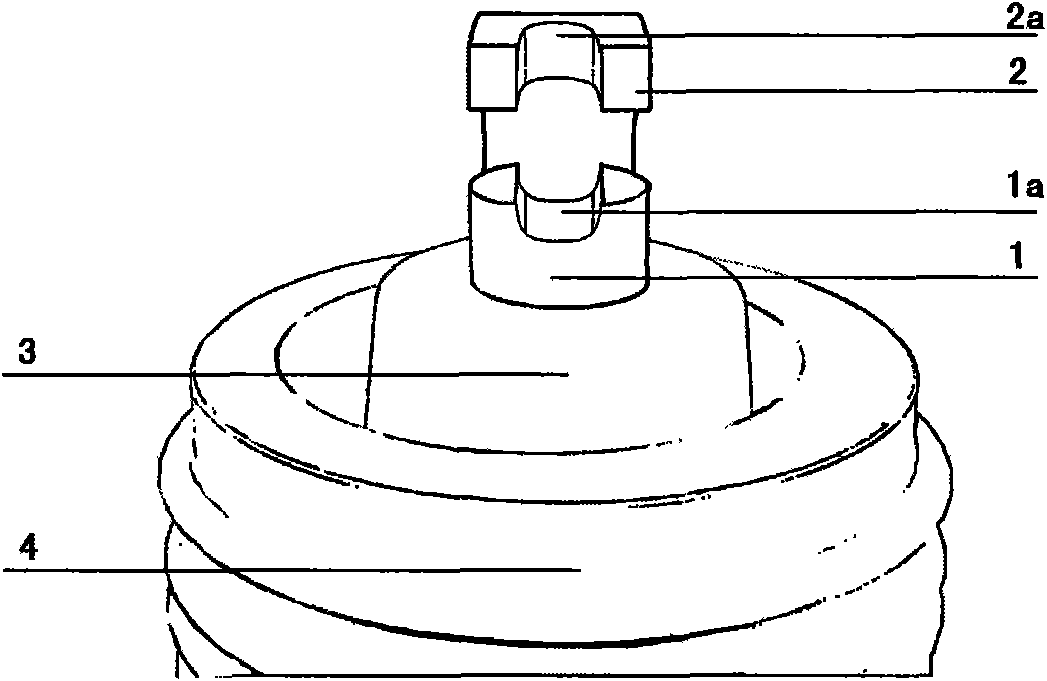

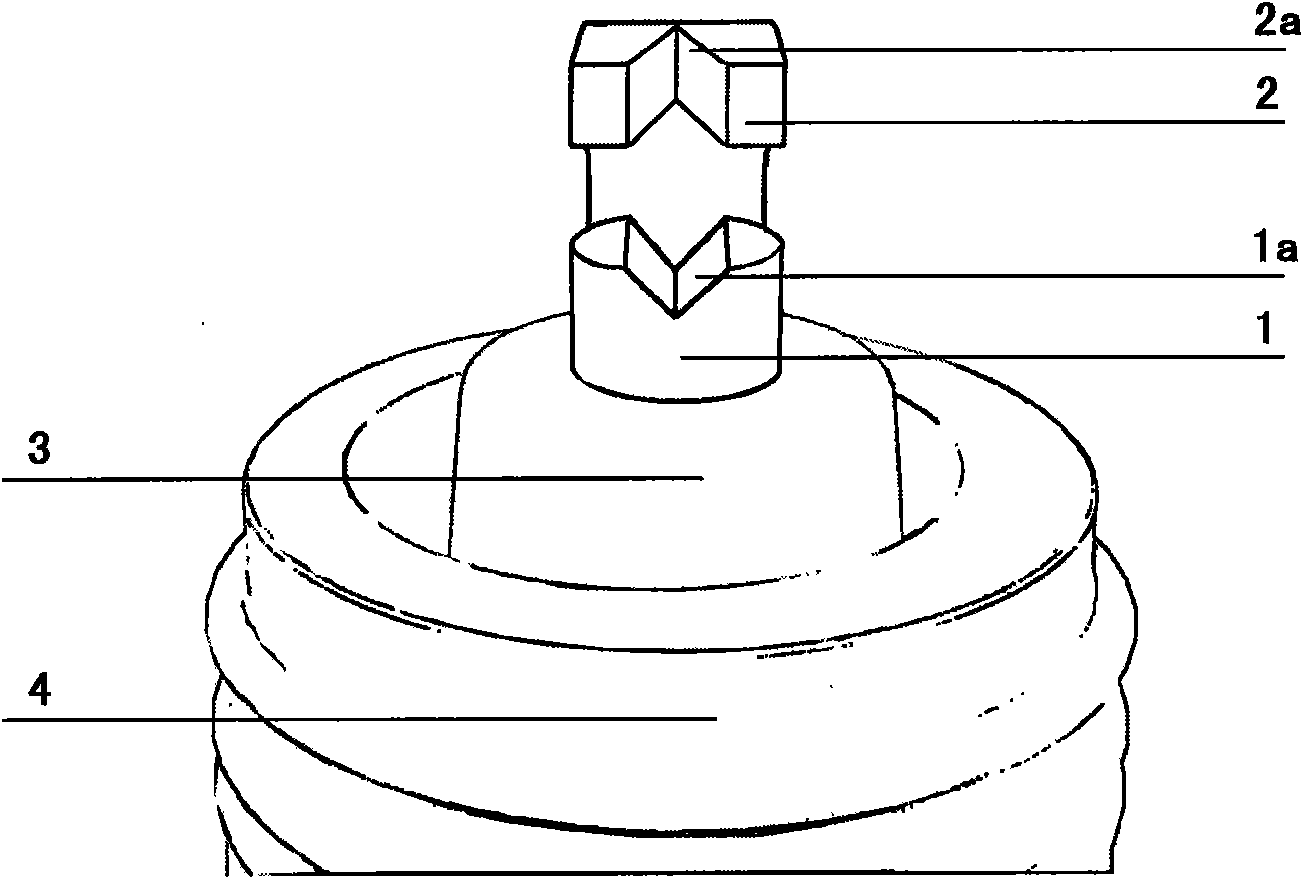

[0009] refer to figure 1 , Weld curved or hook-shaped side electrodes 2 on the shell 3, and open a hollow "V"-shaped groove 2a longitudinally on the cross-section of the discharge end of the side electrode 2. The opening width, depth and apex angle of 2a should be appropriate The central electrode 1 is built in the central hole of the ceramic core 4, and the upper end is exposed on the porcelain surface, and a "V"-shaped concave groove 1a is opened downward in the cross-section of the discharge end of the central electrode 1, and the opening width, depth and apex angle of 1a are The angle should be appropriate. Specific details such as the size and location of each groove need to be determined by system tests.

[0010] Although the concave groove spark plug has been described above with respect to specific embodiments of the present invention, this is only exemplary rather than limiting, and the appended claims should be as broad as the prior art allows understand.

[0011]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com