Silicon wafer pickling and thinning machine

A technology of silicon wafer acid and mixed acid, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult to control the surface state of silicon wafers, difficult to precisely control thickness, poor uniformity, etc., to ensure corrosion efficiency and uniformity. The effect of corrosion resistance, slow corrosion rate and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

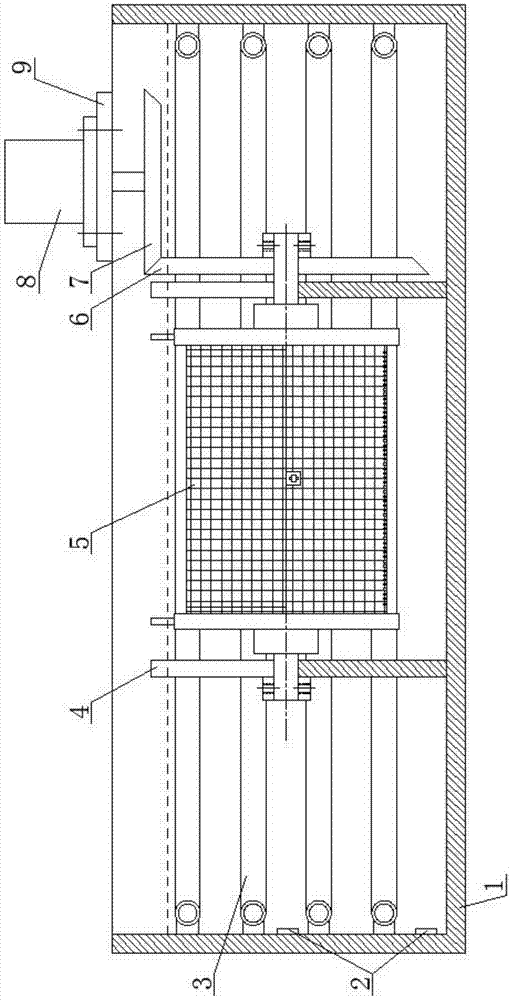

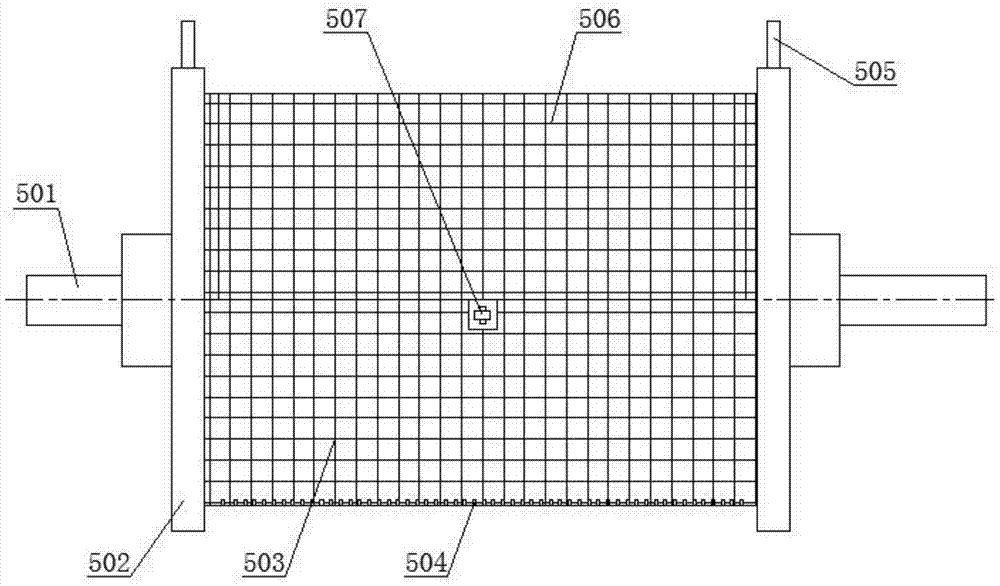

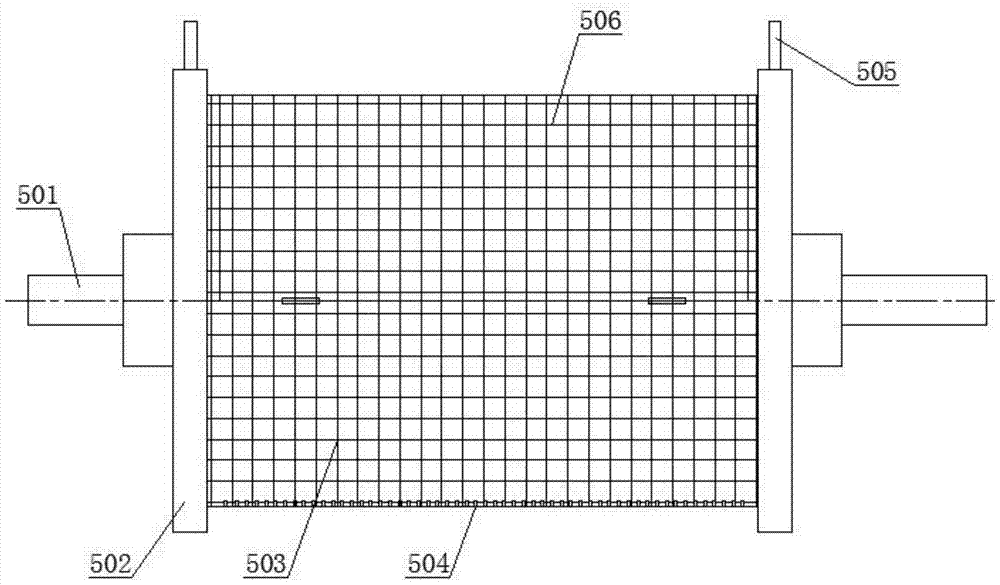

[0031] As shown in the figure, the silicon wafer pickling and thinning machine includes a box body 1 for containing mixed acid liquid, and a bracket is provided in the box body 1 and a rotating basket 5 for clamping silicon wafers 10 is supported by the bracket. The rotating basket 5 is composed of two circular fixing plates 502, a cylindrical cage horizontally connected between the two circular fixing plates 502, a rotating shaft 501 arranged on the outer surface of the two circular fixing plates 502, and symmetrically arranged on the The handle 505 on the outer peripheral surface of two circular fixed plates 502 is formed, and the axial center line of described circular fixed plate 502, cylindrical enclosure and rotating shaft 501 coincides, and described cylindrical enclosure consists of enclosure body 503, and The cage body 503 is composed of a semicircular cage cover 506 hinged. The side edge of the opening of the semicircular cage cover 506 is connected to the cage body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com