Mechanical type descaling device

A descaling, mechanical technology, applied in chemical instruments and methods, dust removal, grinding machines, etc., can solve the problems of large investment, serious environmental pollution, high cost, and achieve the effect of good cooling effect, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

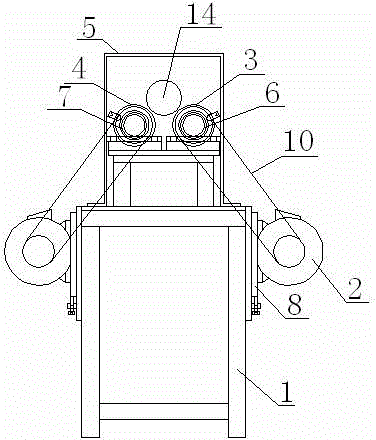

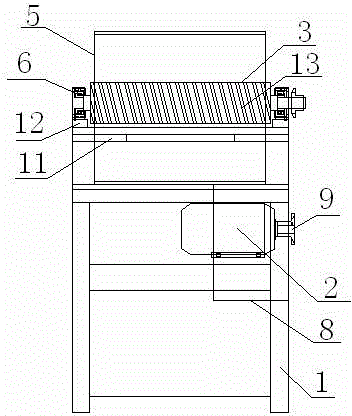

[0015] refer to figure 1 and figure 2 The shown mechanical descaling device includes an underframe 1, two driving devices 2 symmetrically arranged on both sides of the underframe 1, and a first roller 3 and a first roller symmetrically arranged on both sides of the upper part of the underframe 1. The second roller 4, and the dustproof cover 5 that is arranged on the top of the underframe 1, the underframe 1 is provided with a first bearing 6 for supporting and rotating the first roller 3, and the underframe 1 is also provided with A second bearing 7 for supporting and rotating the second roller 4 is provided, and a motor mounting plate 8 for fixing and installing two driving devices 2 is provided on the underframe 1. The output end of device 2 is all provided with motor sprocket 9, and the motor sprocket 9 that is arranged on the output end of two driving devices 2 all adopts chain 10 to link to each other with the input end of first roller 3 and second roller 4, The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com