Improved skein dyeing machine

A hank dyeing machine, an improved technology, is applied in the directions of spray/jet textile material processing, textile material processing equipment configuration, etc., which can solve the problems of deformation of the liquid spray pipe, high manufacturing cost, and very high sealing requirements, and meet the sealing requirements. Reduction, low manufacturing cost, effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

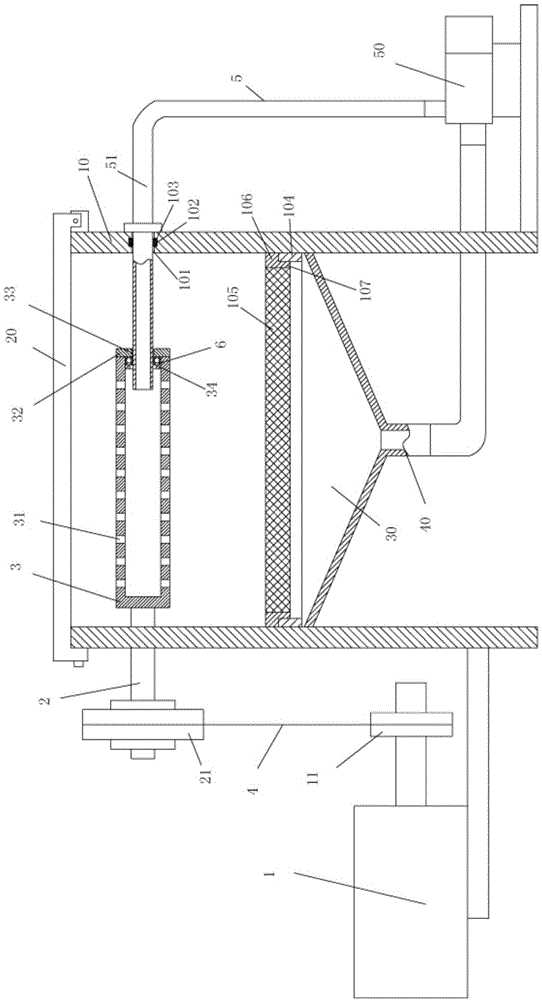

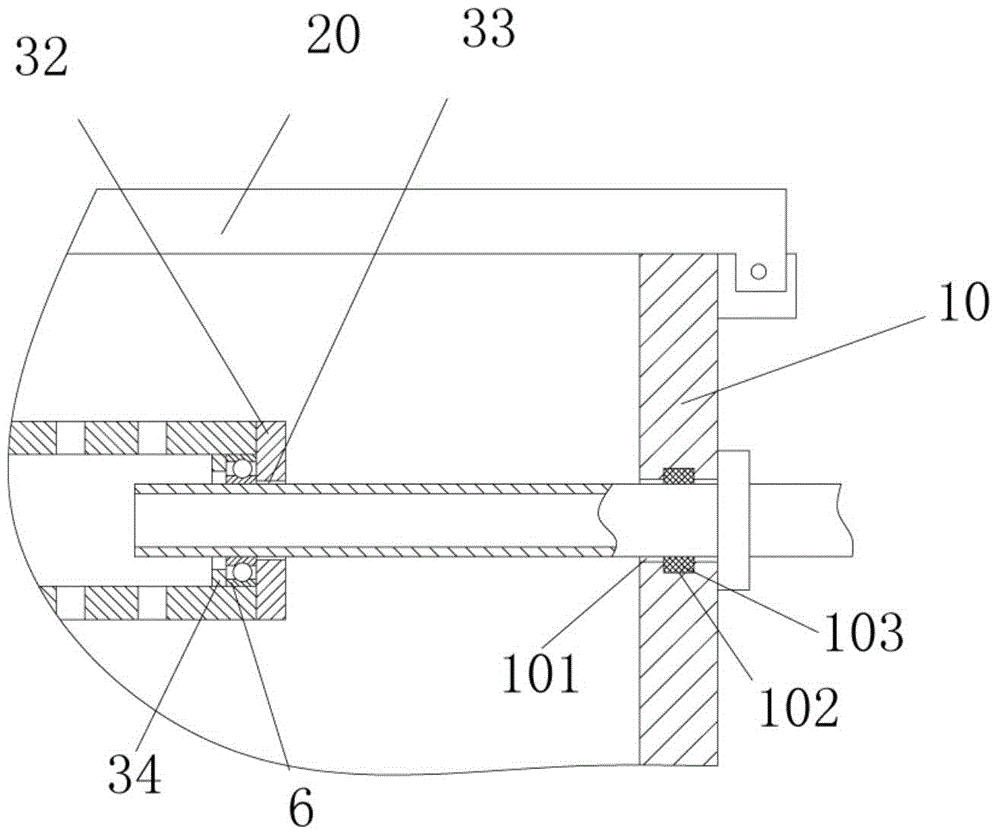

[0017] Examples, see e.g. Figure 1 to Figure 2 Shown, a kind of improved skein dyeing machine comprises frame 10 and machine cover 20, and one end of machine cover 20 is hinged on the top of frame 10, and machine cover 20 covers on frame 10, and described frame 10 Rotating motor 1 is fixed on the left side of the rotating motor 1, output sprocket 11 is fixed on the output shaft of rotating motor 1, and rotating shaft 2 is hinged on the top of the left side plate of frame 10, and the front end of rotating shaft 2 stretches in the frame 10 and The liquid spray pipe 3 is fixed, the part of the rotating shaft 2 outside the frame 10 is fixed with a transmission sprocket 21, and the chain 4 is tensioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com