Reaction joining waterproof roll paving waterproof construction method

A technology of waterproof roll material and construction method, which is applied in water conservancy projects, sea area projects, earthwork drilling and mining, etc., to meet the waterproof requirements and ensure the quality of paving and pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

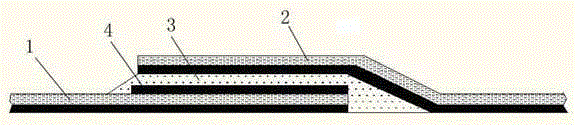

[0030] Set the reference line on the base surface in advance, the width of the first reference line closest to the wall and the wall is consistent with the width of the single-sided reactive adhesive waterproof roll, and the width between the remaining reference lines is the single-sided reactive adhesive waterproof roll The width of the material after deducting the width of the lap edge.

[0031]Lay the single-sided reactive adhesive waterproof membrane on the ground with the reactive adhesive layer facing the base surface, and then fold it in half. Tear off the isolation film on the upward facing reactive adhesive layer after folding. Scrape and coat a layer of 1.5-2.5mm thick cement slurry on the reactive adhesive layer, and scrape a layer of 1.5-2.5mm thick cement slurry on the corresponding base surface, then re-roll the reactive adhesive waterproof membrane, Make the reaction adhesive adhesive layer coated with cement slurry fit the base surface of the scraped cement slu...

Embodiment 2

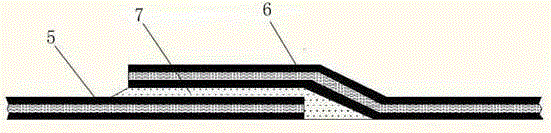

[0035] Before laying the double-sided reactive adhesive waterproof membrane on the ground, set the reference line on the base surface in advance. The width of the first reference line closest to the wall and the wall is the same as the width of the double-sided reactive adhesive waterproof membrane, and the rest The width between the reference lines is the width after the superimposed width of the double-sided reactive adhesive waterproof membrane width buckle.

[0036] Lay the double-sided reactive adhesive waterproof membrane on the ground first according to the reference line, then fold it in half, tear off the isolation film on the reactive adhesive layer that is folded in half, and spread a layer of 1.5 to 2.5 mm on the reactive adhesive layer. mm thick cement slurry, a layer of 1.5-2.5mm thick cement slurry is also spread on the corresponding base surface, and then the double-sided reactive adhesive waterproof membrane is re-rolled, so that the reactive adhesive adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com