Deep buried central gutterway inspection well structure for cold region tunnel

A technology for central water ditch and tunnel in cold area, applied in the direction of tunnel, tunnel lining, drainage, etc., can solve the problems of unfavorable thermal insulation and poor sealing, and achieve the effect of preventing heat transfer, ensuring thermal insulation effect, and isolating heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and example the present invention will be further described:

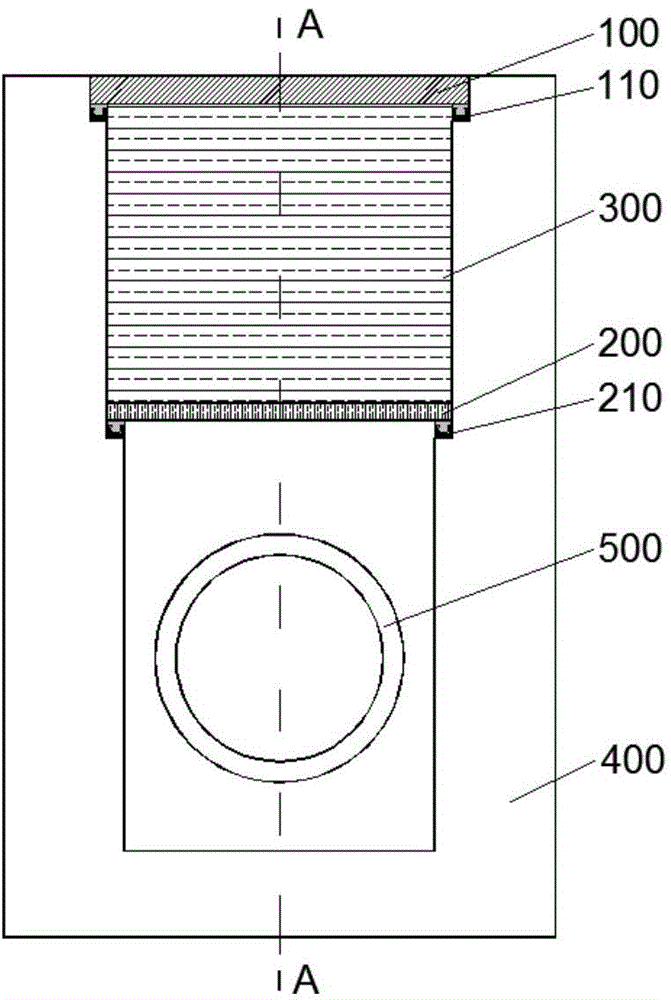

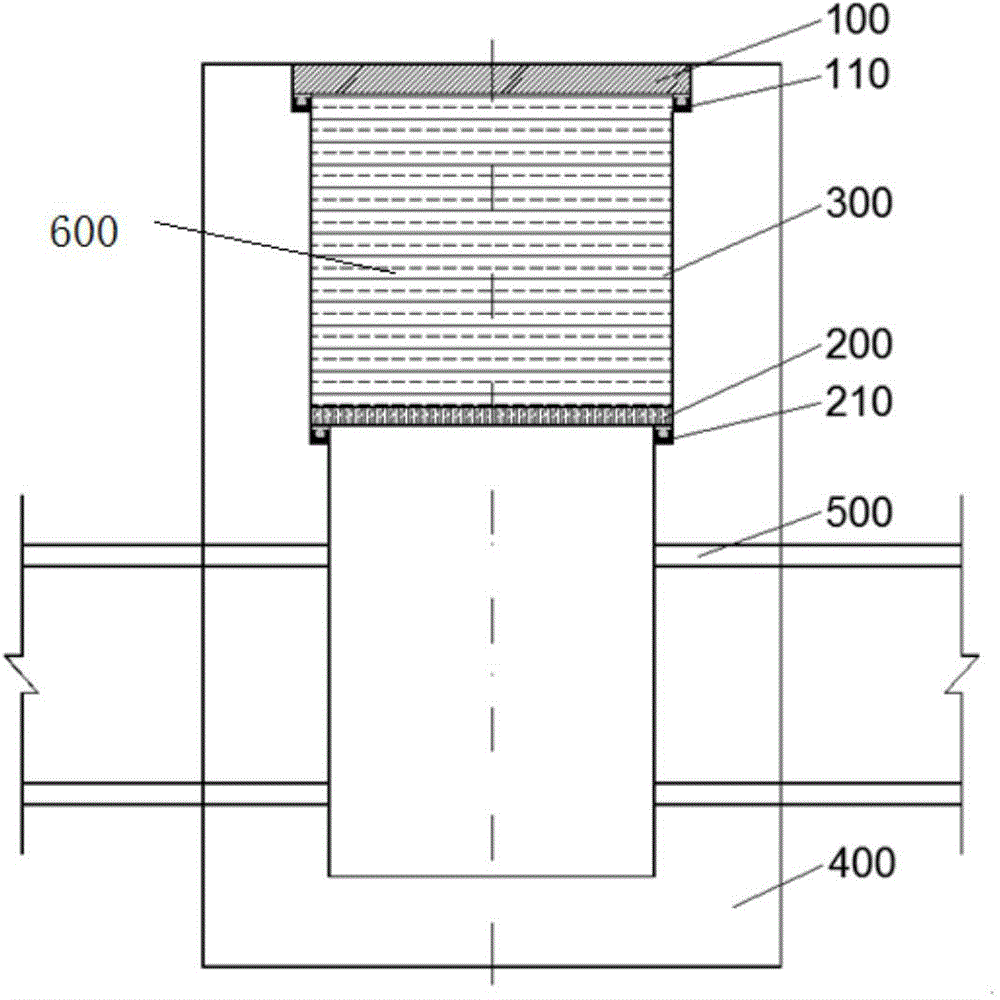

[0024] combine figure 1 and figure 2 It can be seen that an inspection well structure for deep buried central ditch of tunnels in cold regions, in a variable cross-section inspection well arranged perpendicular to the central deep buried ditch 500, the upper cover 100 and the lower cover vertically placed on the shaft wall 400 A closed space 300 is formed between the plates 200; an airtight sealing mechanism (110 and 210) is provided at the junction of the upper cover plate and the lower cover plate and the well wall.

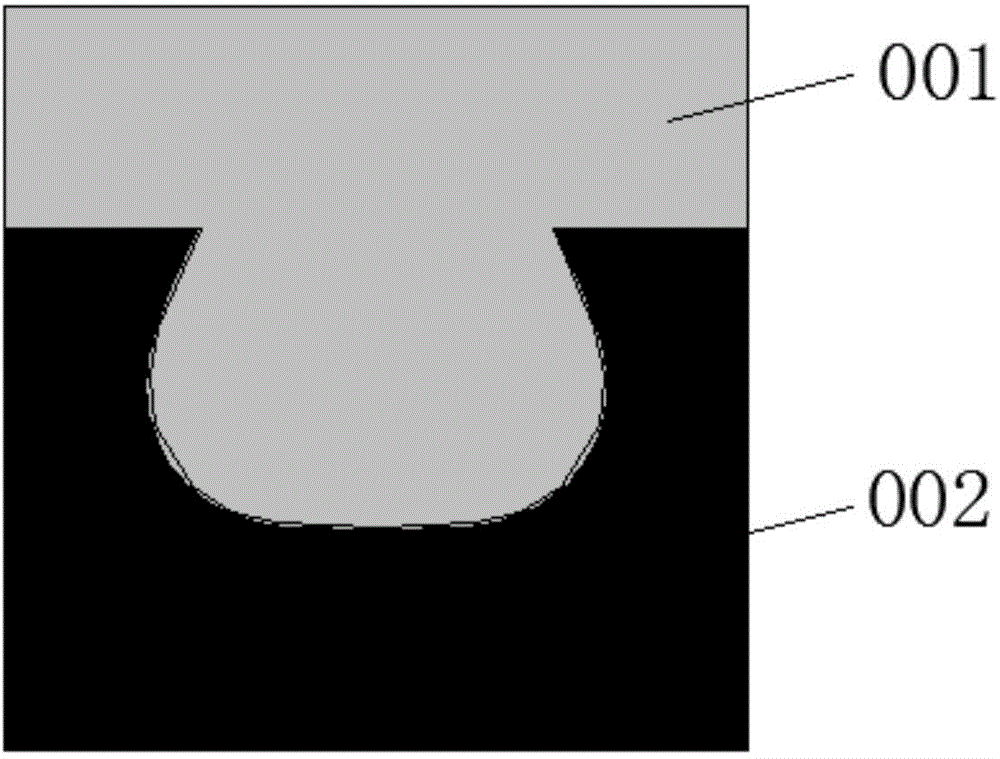

[0025] combine image 3 It can be seen that the airtight sealing mechanism (110 and 210) is a male-female paired engagement structure, that is, the male gasket placed on the lower part of the cover plate has a recess 002 of the female gasket arranged on the well wall. Convex 001.

[0026] A new type of inspection well structure used for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com