Wood structure flame-retardant coating and preparation method thereof

A flame retardant coating and wood structure technology, applied in the field of flame retardant materials, can solve problems such as poor performance of water-based flame retardant coatings, and achieve the effects of improving strength, low thermal conductivity and reducing smoke emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method for preparing the above-mentioned wood structure flame retardant coating, the steps are as follows:

[0038] A water phase preparation: take materials according to the weight ratio of each component, mix water, additives and titanium dioxide evenly, then add water-based film-forming matrix, intumescent flame retardant and graphene-like substances, and stir evenly;

[0039] B flame retardant powder additive preparation: according to the weight ratio of each component, methoxy acrylic resin, P-N composite flame retardant, inorganic filler, aluminum hydroxide and antimony halide are mixed and stirred evenly;

[0040] C Finished product preparation: Mix component A and component B according to the weight ratio, and sieve and discharge after grinding.

[0041] Among them, when stirring in the preparation of component A, keep the rotation speed at 1000-1200r / min; when stirring in the preparation of component B, keep the rotation speed at 800-1000r / min; ...

Embodiment 1

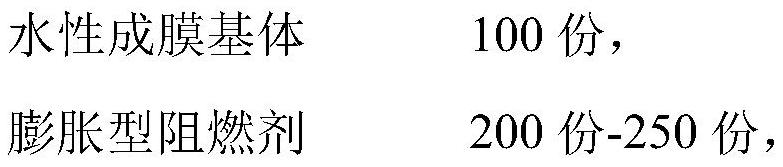

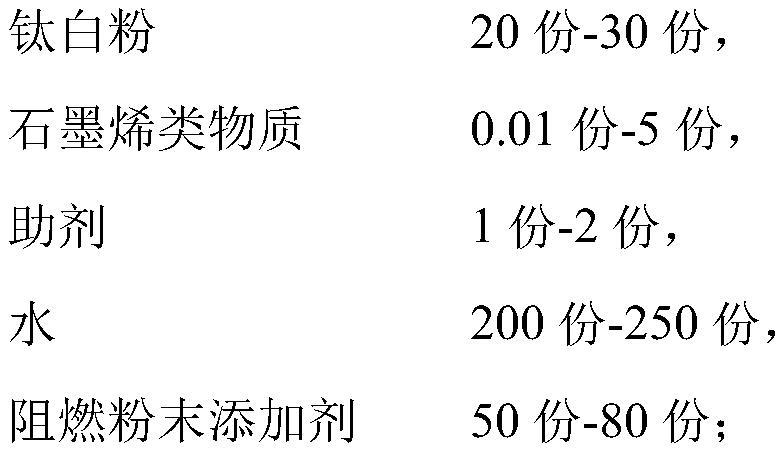

[0042] Embodiment 1: A kind of wooden structure flame retardant coating, comprises the following components in parts by weight: 100 parts of aqueous film-forming substrates, 200 parts of intumescent flame retardants, 20 parts of rutile titanium dioxide, 0.03 parts of graphene, additives 1 part, 200 parts of water, 50 parts of flame retardant powder additive.

[0043] Wherein the flame retardant powder additive includes methoxy acrylic resin, P-N composite flame retardant, inorganic filler, aluminum hydroxide and antimony halide.

[0044]The weight ratio of methoxyacrylic resin, P-N composite flame retardant, inorganic filler, aluminum hydroxide and antimony halide in the flame retardant powder additive is 15:10:10:10:5. The P-N composite flame retardant is melamine polyphosphate (MMP), and the antimony halide is antimony chloride. The inorganic filler is talcum powder.

[0045] Auxiliaries include film-forming aids, dispersants, thickeners, leveling agents, defoamers; graphe...

Embodiment 2

[0051] Embodiment 2, a fire-retardant coating for wood structures, including the following components in parts by weight: 100 parts of water-based film-forming substrate, 250 parts of intumescent flame retardant, 30 parts of titanium dioxide, 1 part of graphene-like substances, and additives 2 parts, 250 parts of water, 80 parts of flame retardant powder additive.

[0052] Wherein the flame retardant powder additive includes methoxy acrylic resin, P-N composite flame retardant, inorganic filler, aluminum hydroxide and antimony halide. The inorganic filler is active calcium carbonate.

[0053] The weight ratio of methoxyacrylic resin, P-N composite flame retardant, inorganic filler, aluminum hydroxide and antimony halide in the flame retardant powder additive is 35:30:45:18:15. The P-N composite flame retardant is melamine polyphosphate, and the antimony halide is antimony bromide.

[0054] Titanium dioxide is anatase titanium dioxide; additives include film-forming aids, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com