Air inlet passage water filtering device

A technology of air intake and air intake duct, applied in the direction of fuel air intake and other directions, can solve the problems of unusable filter element, suction collapse, and filter element folding, etc., to achieve simple structure, convenient manufacturing and installation, and increase intake resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

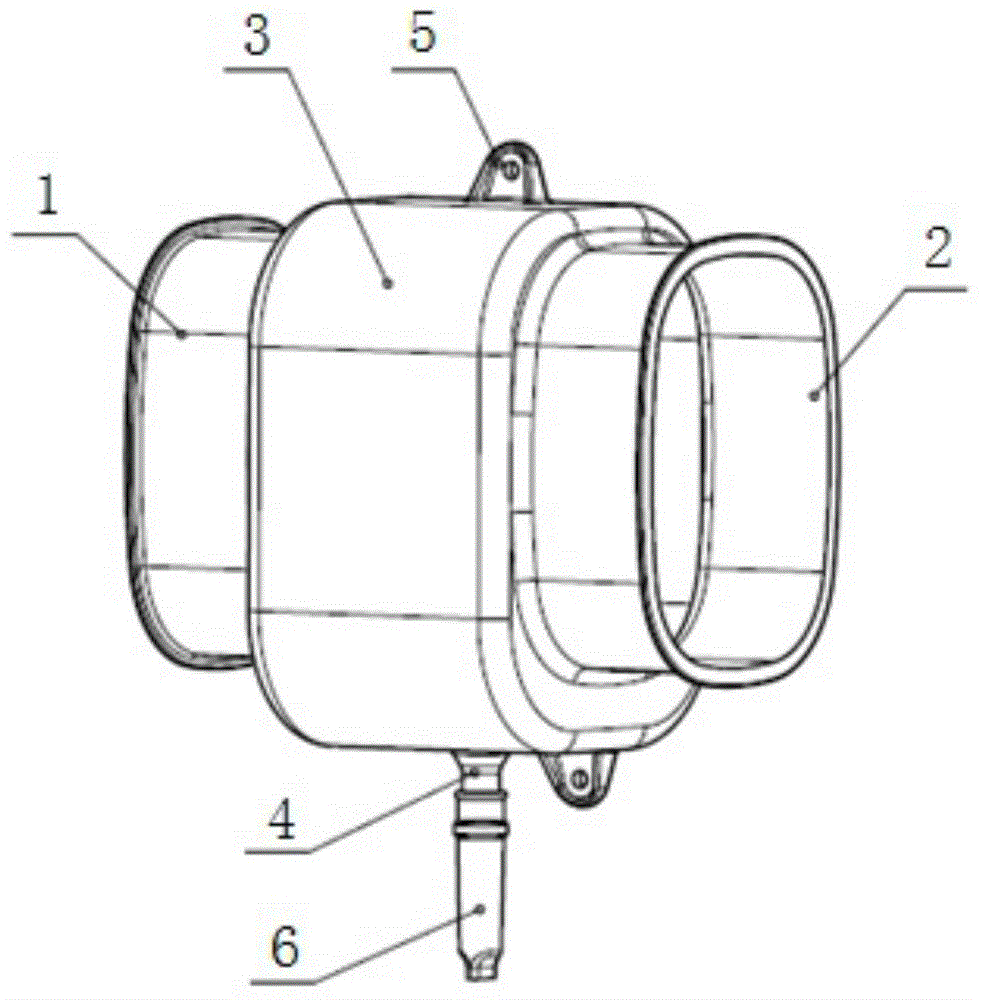

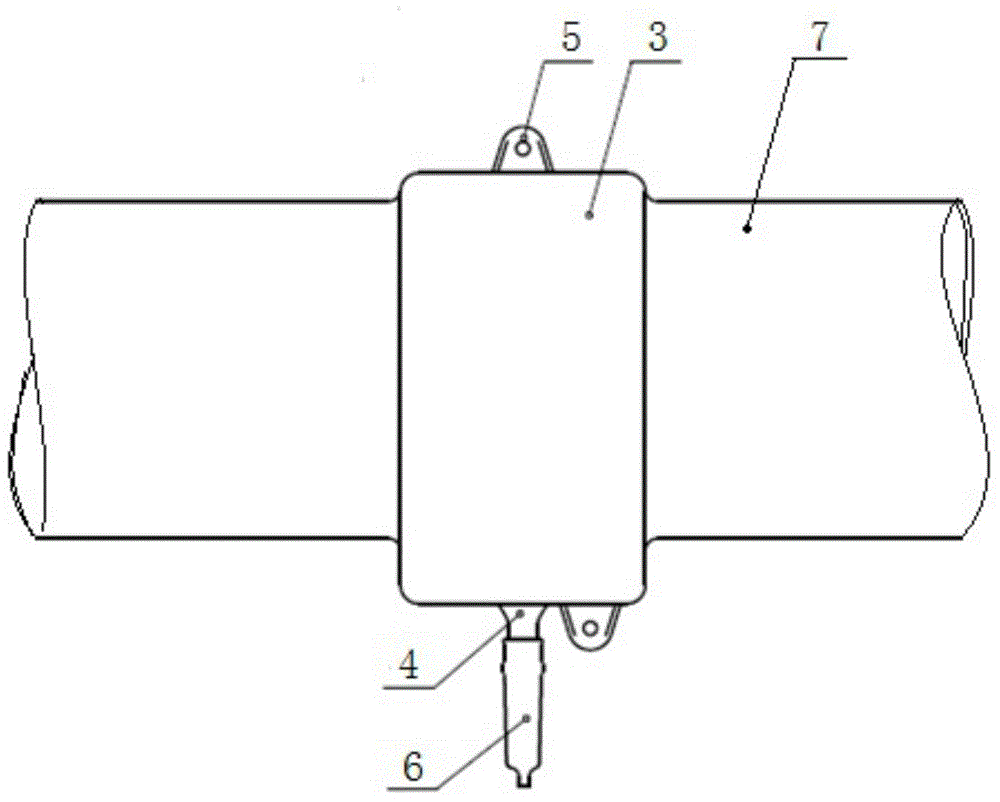

[0013] figure 1 Shown is the structural representation of the present invention.

[0014] The present invention comprises an air inlet 1, an air outlet 2, a filter chamber 3 and a water outlet 4.

[0015] The filter cavity 3 is a cavity structure, and its two ends are respectively provided with an air inlet 1 and an air outlet 2 .

[0016] The cross-sectional area of the filter cavity 3 is greater than the cross-sectional areas of the air inlet 1 and the air outlet 2 .

[0017] The bottom of the filter cavity 3 is provided with a drain port 4, and the drain port 4 is connected with a drain pipe 6, and the drain pipe 6 is arranged as a slender structure, which ensures that the water droplets will not be taken away by the airflow again after entering the drain pipe. When the water droplets gather to a certain height in the drain pipe, under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com