Oil Filtration System and Air Conditioning Unit

A technology for air conditioning units and oil filtration, which is used in mechanical equipment, engine components, and engine lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

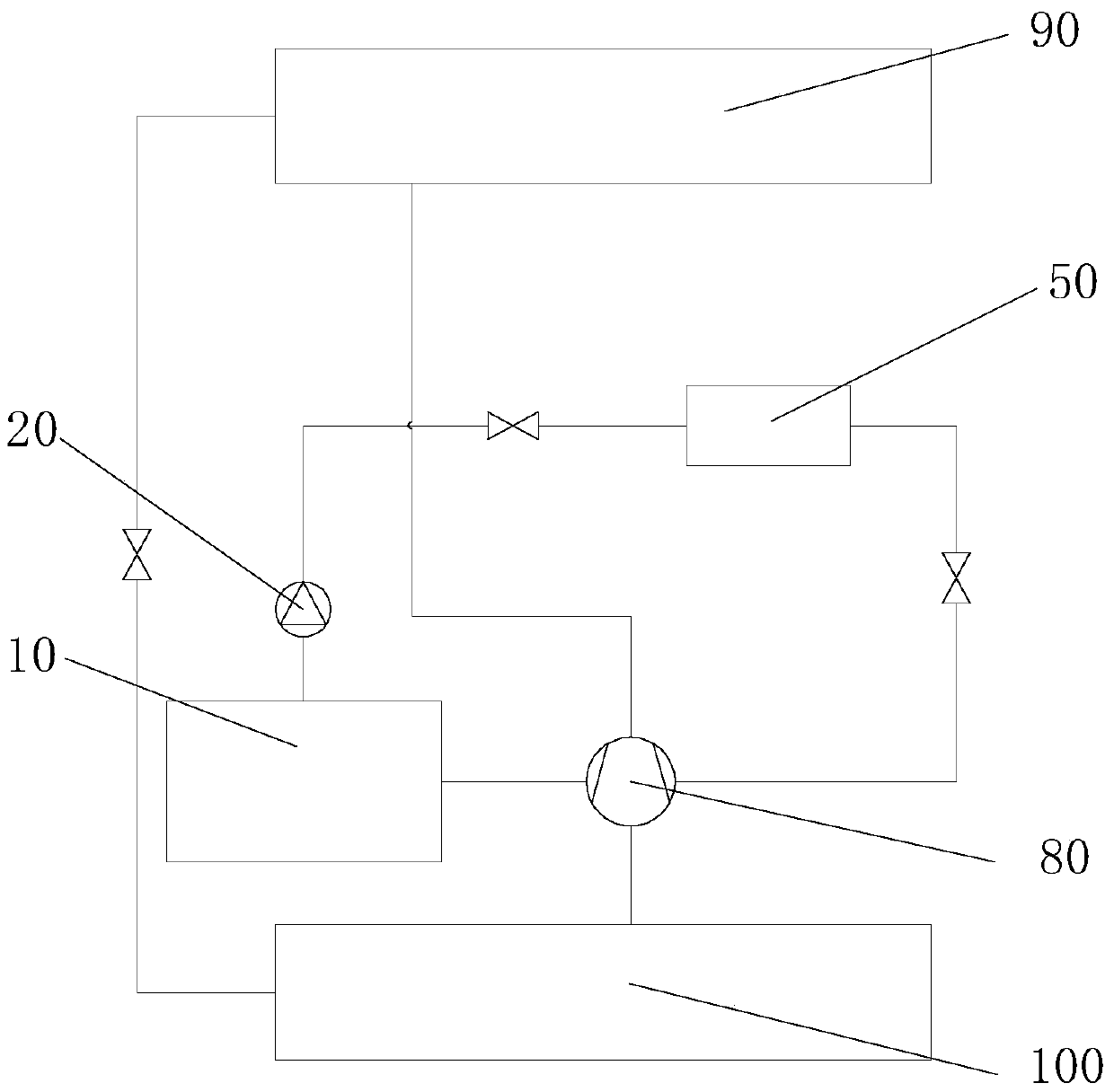

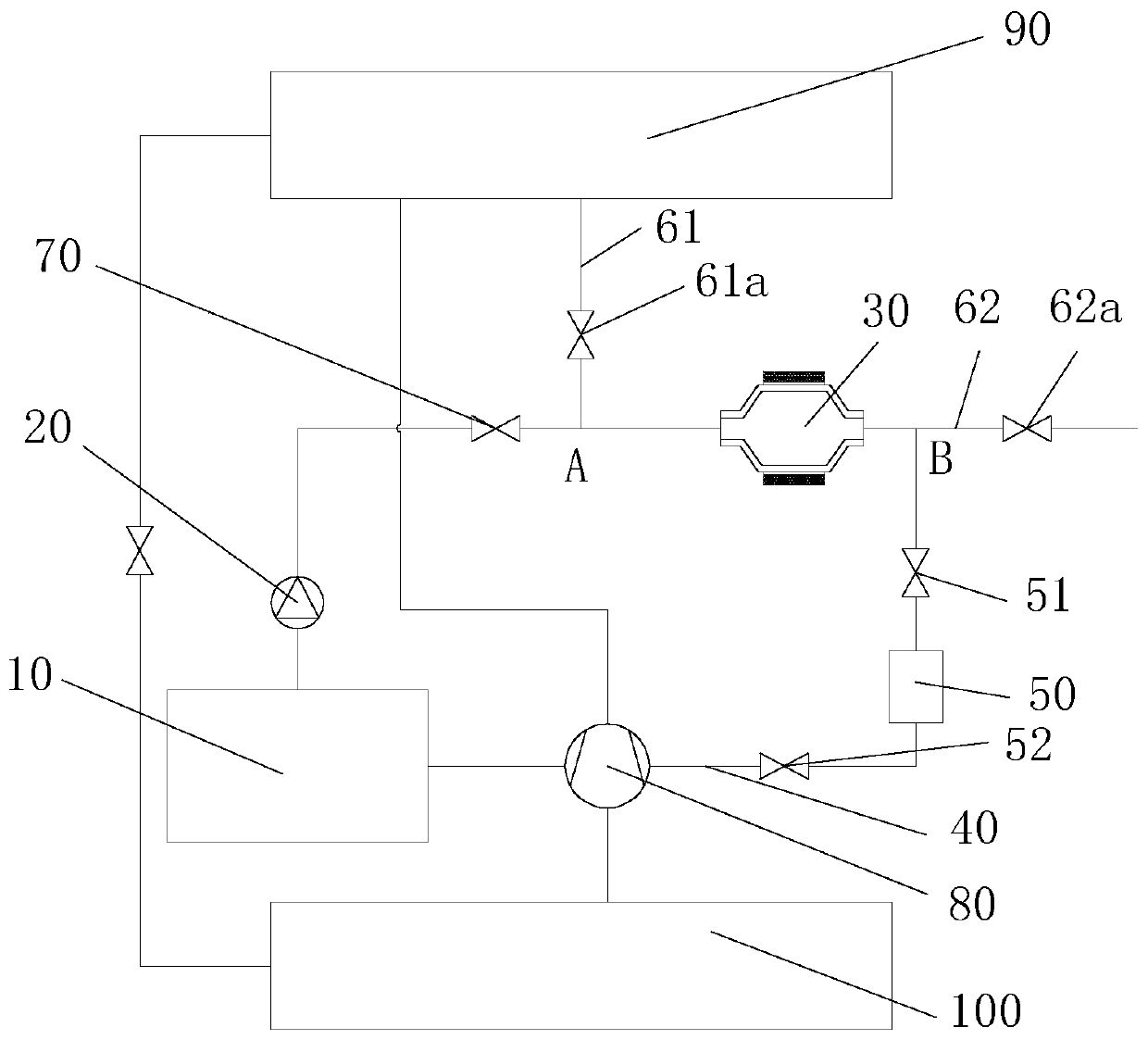

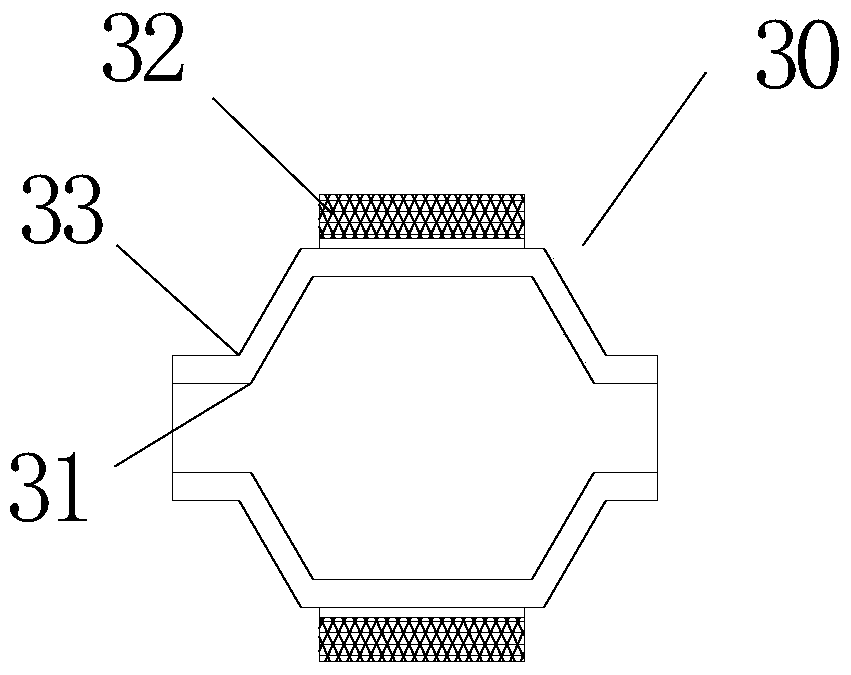

[0024] like figure 2 As shown, the oil filtration system according to the present invention includes: an oil tank 10 for containing oil; an output pipeline connected to the oil tank 10 for leading out the oil in the oil tank 10, and a first output node A is provided on the output pipeline; The electronically controlled magnetic filter 30 is connected to the first output node A; the lubricating oil circuit 40 is connected to the output end of the electronically controlled magnetic filter 30 . In the present invention, an electronically controlled magnetic filter 30 is arranged on the oil circuit. Under the power-on state, the electronically controlled magnetic filter 30 has magnetism and can absorb impurities such as iron filings in the lubricating oil; When the magnetism is lost, the iron filings adsorbed on the electronically controlled magnetic filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com