A kind of breeding sewage treatment process

A treatment process and aquaculture sewage technology, applied in the field of aquaculture sewage treatment technology, can solve the problems of poor treatment effect of ammonia nitrogen and organic pollutants, poor removal effect of solid suspended solids, and inability to directly use sludge, and achieve good removal effect and installation. The effect of easy disassembly and low disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

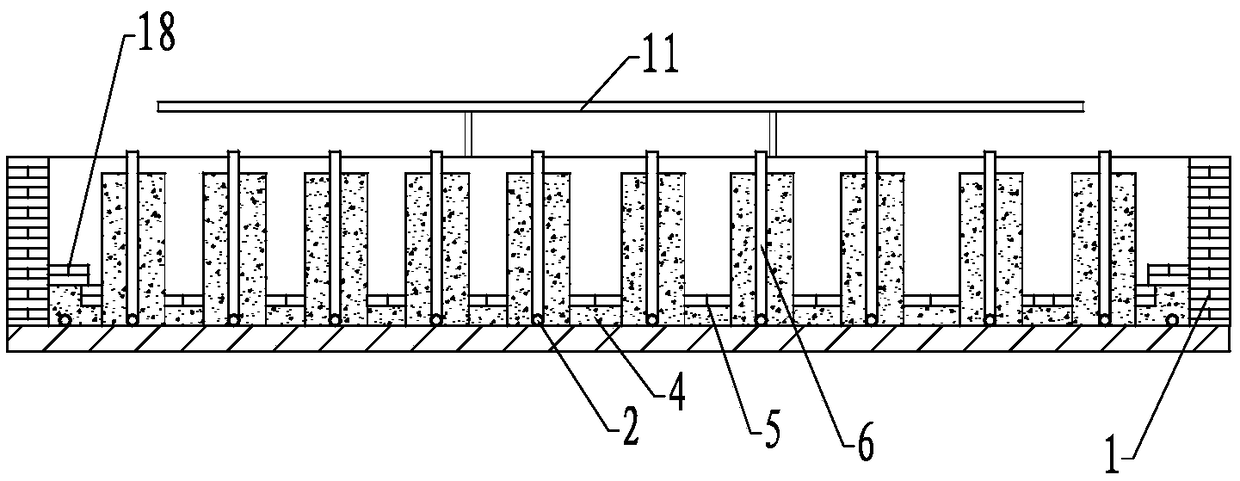

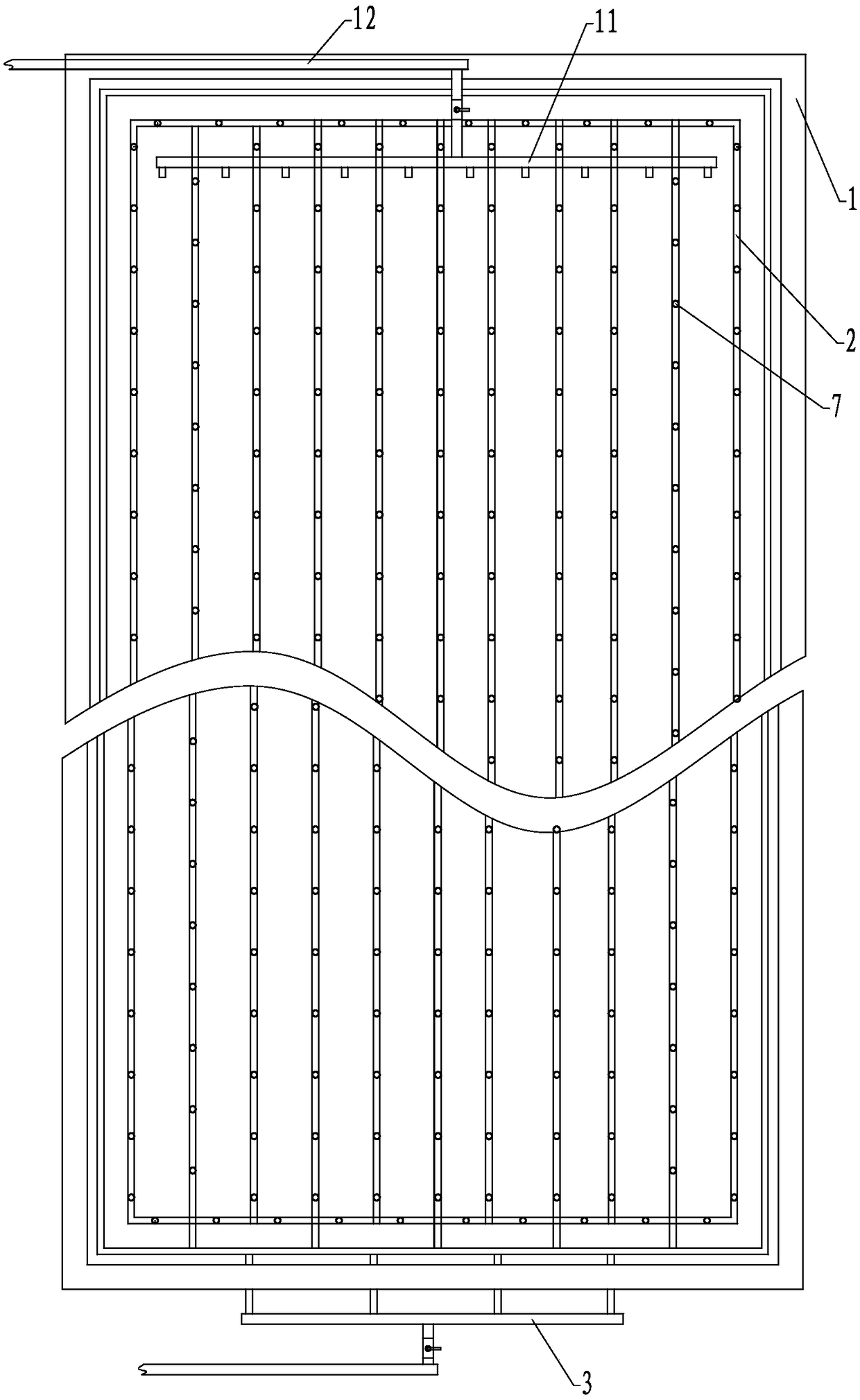

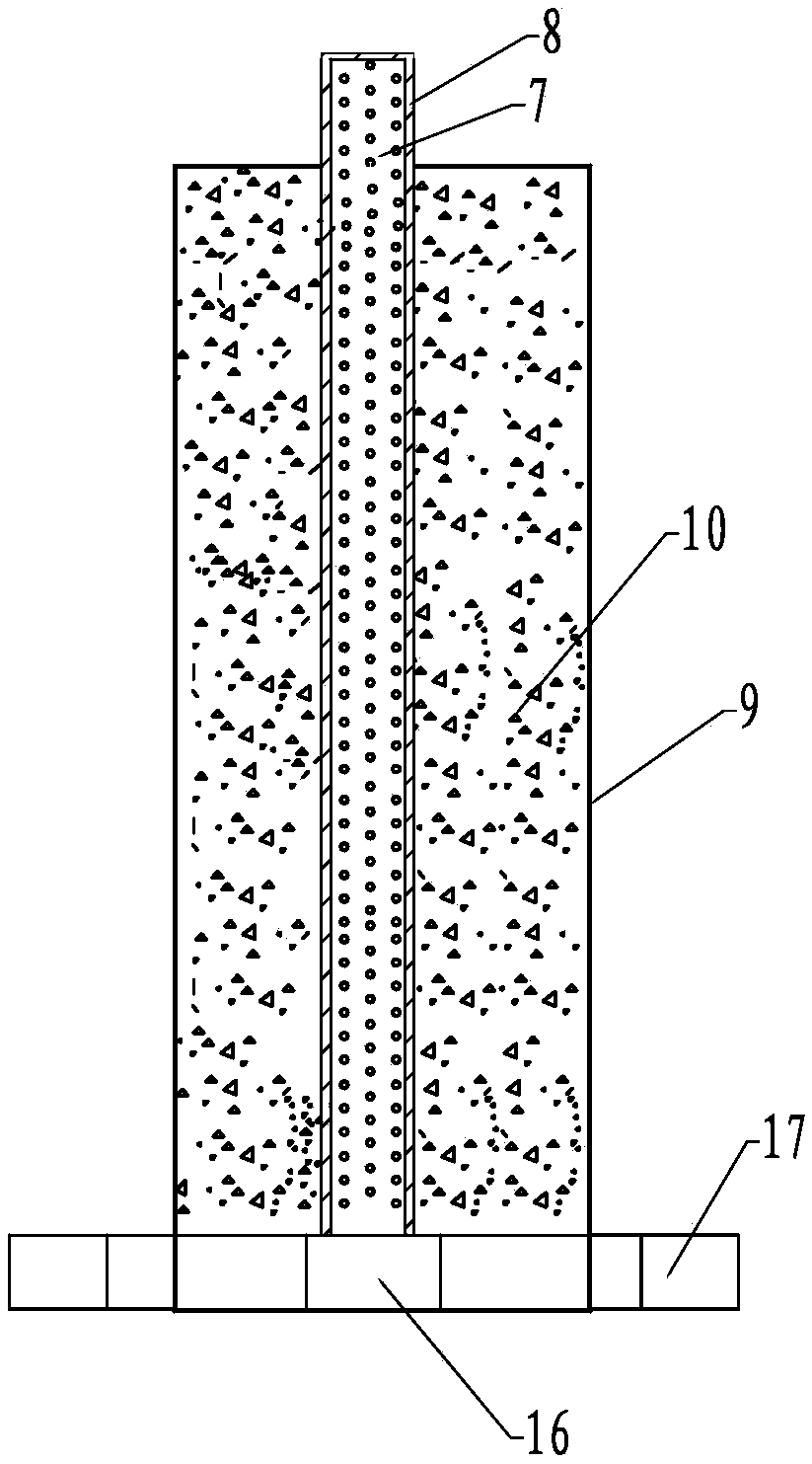

[0023] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0024] A kind of aquaculture sewage treatment process adopts the following process steps:

[0025] (1) The lifting well collects the sewage discharged from the farm;

[0026] (2) Transport the sewage in the lifting well to the biological filter tank for filtering;

[0027] (3) Use the suspended solids obtained in step (2) as organic fertilizer, transport the sewage after filtering the suspended solids to an anaerobic reactor, and carry out anaerobic fermentation at 15-25°C for 20-30 days, Removal of organic pollutants in sewage;

[0028] (4) using the biogas produced by anaerobic fermentation in step (3) as biomass fuel, transporting the sewage after anaerobic fermentation to the ammoxidation reactor, and performing the ammoxidation reaction at 15-25° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com