Tool for inspecting filter element replacement system and use method of tool

A technology of filter elements and tools, which is applied in the field of tools for checking and accepting filter element replacement systems, can solve the problems of high cost and low efficiency in the acceptance of filter element replacement systems, and achieve the effects of high cost, simple structure, and guaranteed construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

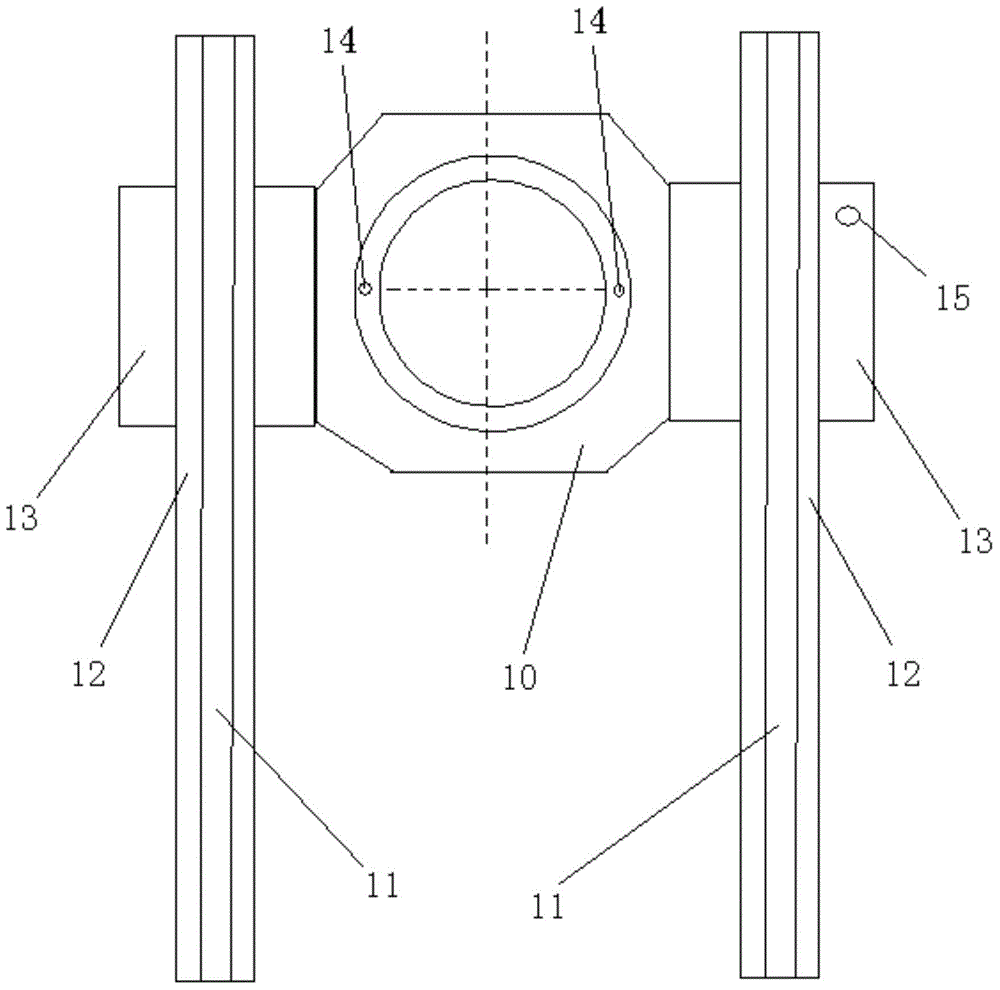

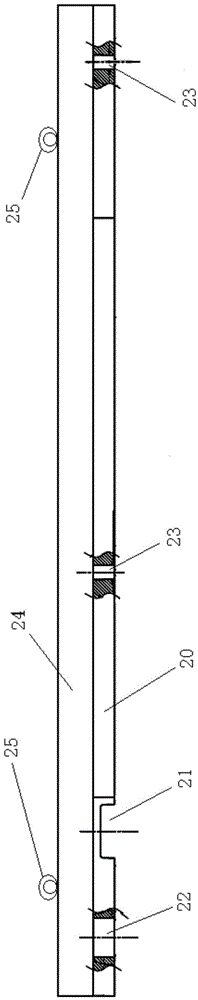

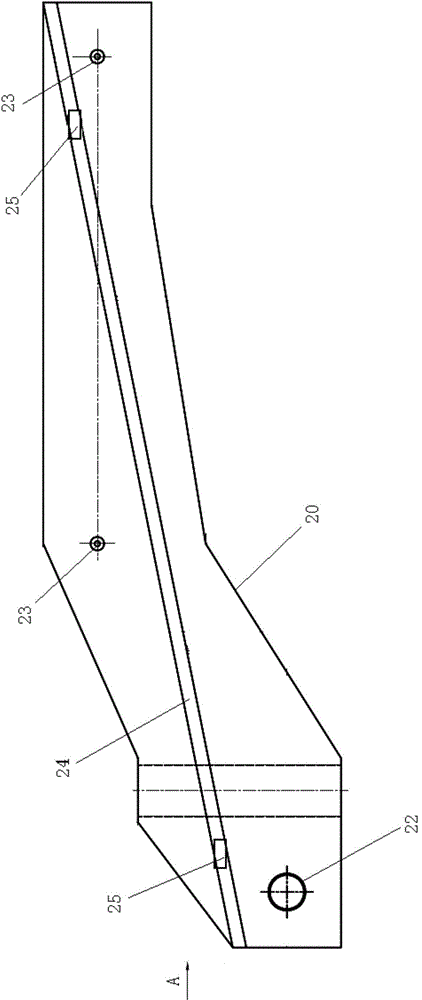

[0023] Combine below Figure 1-Figure 4 The tool of the present invention is introduced.

[0024] Such as Figure 1-Figure 4 As shown, the tool of the present invention includes an acceptance plate 20 , and the acceptance plate 20 is provided with a card slot 21 , a first pin hole 22 and two second pin holes 23 . The draw-in slot 21 cooperates with the track required by the design of the filter element replacement system. The diameter of the first pin hole 22 is the same as the diameter of the index plate mounting hole 15 on the fixing plate 13 of the filter element replacement system. The diameter of the second pin hole 23 is the same as the diameter of the filter element installation hole 14 on the filter frame 10 of the filter element replacement system. The position of the card slot 21, the first pin hole 22 and the second pin hole 23 on the acceptance plate 20 is set according to the design requirements of the position of the track 11, the index plate installation hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com