Noncontact testing method for inherent frequency and quality factor of resonance coil

A technology of natural frequency and quality factor, which is applied in the field of measurement of natural frequency and quality factor of resonant coils, and can solve the problems of error, inaccurate measurement results, and large impedance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

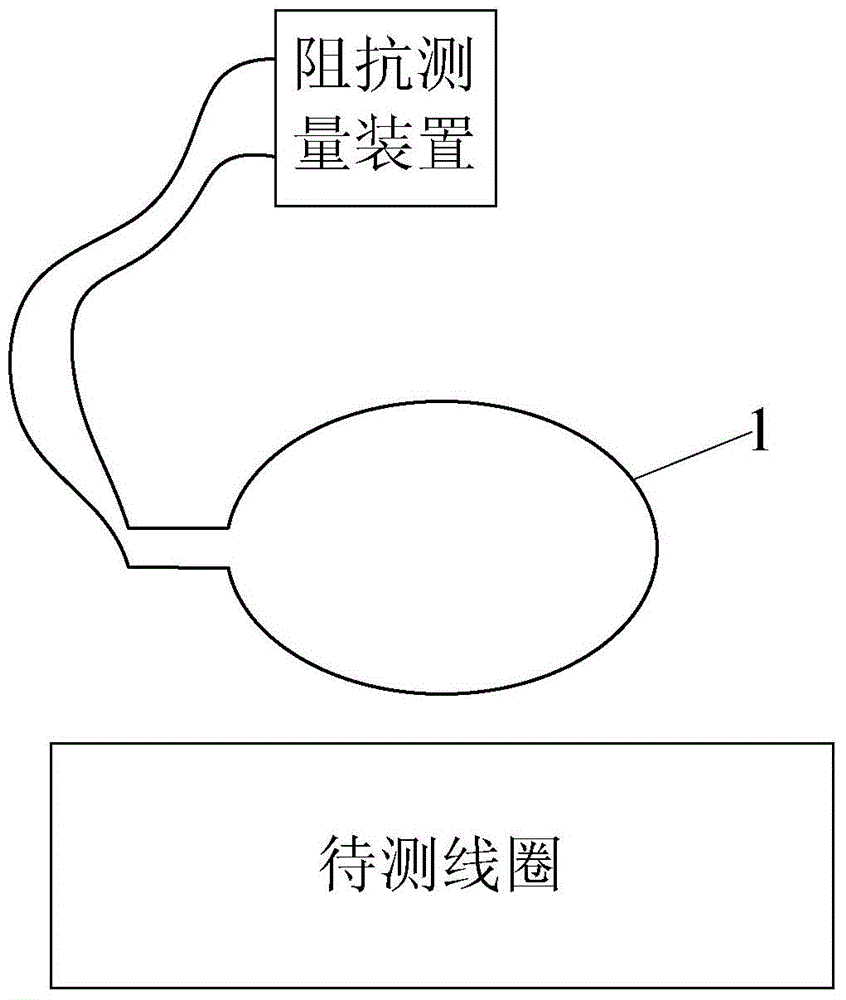

[0022] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the non-contact method for measuring the natural frequency and quality factor of a resonant coil described in this embodiment includes the following steps:

[0023] Step 1, connect the standard coil 1 of the impedance measuring device;

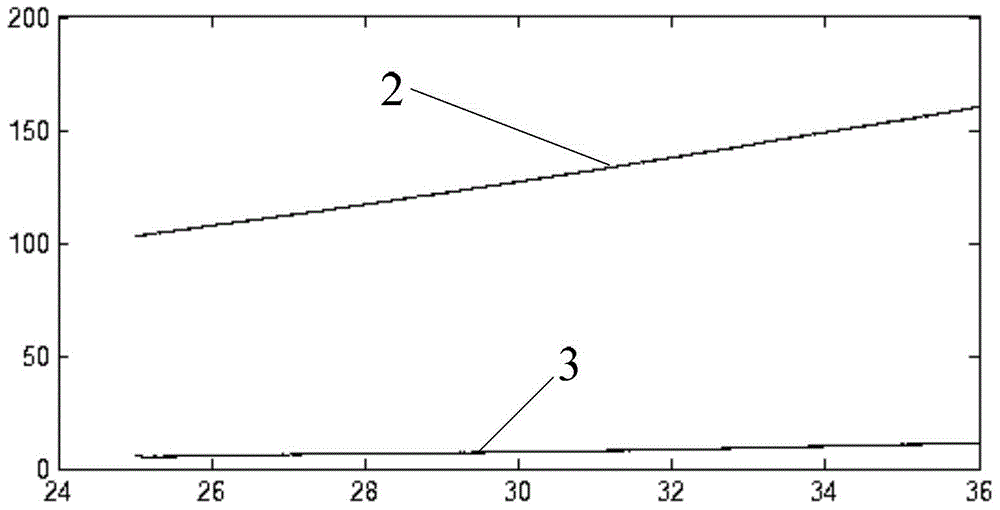

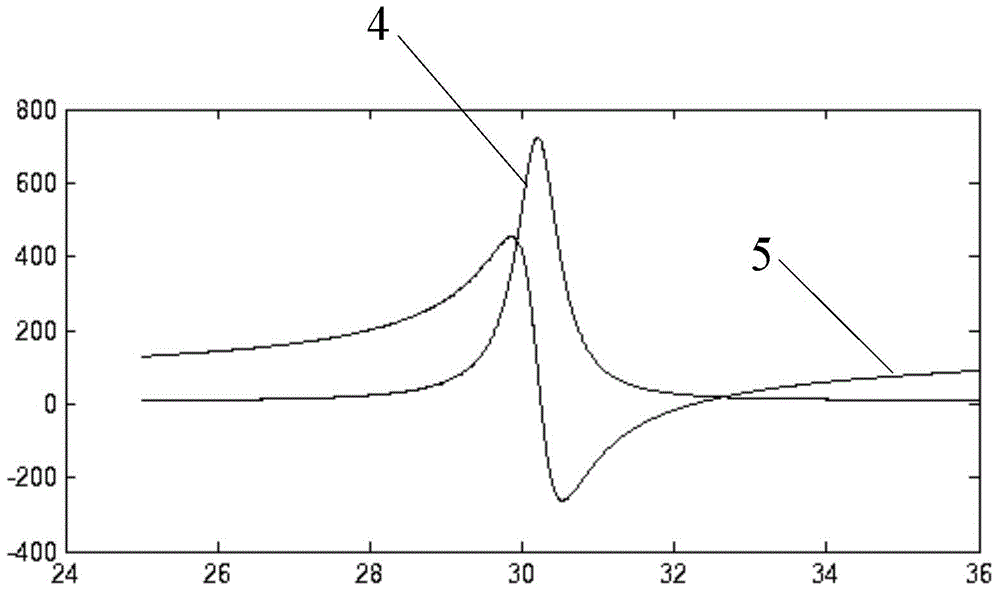

[0024] Step 2. Utilize the impedance measuring device to measure the real part Real(Z) of the impedance of the standard coil 1 S (f)) and imaginary part Imag(Z S (f)) a curve varying with frequency, the range of said frequency is 0-20M; Z represents impedance;

[0025] Step 3. Coupling the standard coil 1 and the coil to be tested through a weak magnetic field strength;

[0026] Step 4: Utilize the impedance measuring device to measure the real part Real(Z) of the impedance of the standard coil 1 0 (f)) and imaginary part Imag(Z 0 (f)) a curve that varies with frequency, f represents frequency, and the range of said frequency is 0-20M;

[0027] Step ...

specific Embodiment approach 2

[0034] Specific Embodiment 2: This embodiment is a further limitation of the non-contact measurement method for the natural frequency and quality factor of the resonant coil described in Embodiment 1. In this embodiment, the impedance measurement device is an impedance analyzer or a network analyzer instrument.

specific Embodiment approach 3

[0035] Specific Embodiment 3: This embodiment is a further limitation of the non-contact measurement method for the natural frequency and quality factor of the resonant coil described in Embodiment 1. In this embodiment, the connection between the impedance measuring device and the standard coil 1 adopts coaxial cable or twisted pair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com