A Multivariate, Fine and Intelligent Carcass Meat Grading Method on Automatic Pig Slaughtering Line

An automatic hog grading method technology, applied in slaughtering, processed meat, meat processing equipment, etc., can solve the problems of large differences in the quality of slaughtered pork, not fully reflecting the impact, and being unable to judge the price by quality. The effects of meat grading are reasonable and scientific, transparency and fairness are improved, and fine settlement is facilitated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the drawings and specific embodiments of the specification, but the embodiments do not limit the present invention in any form.

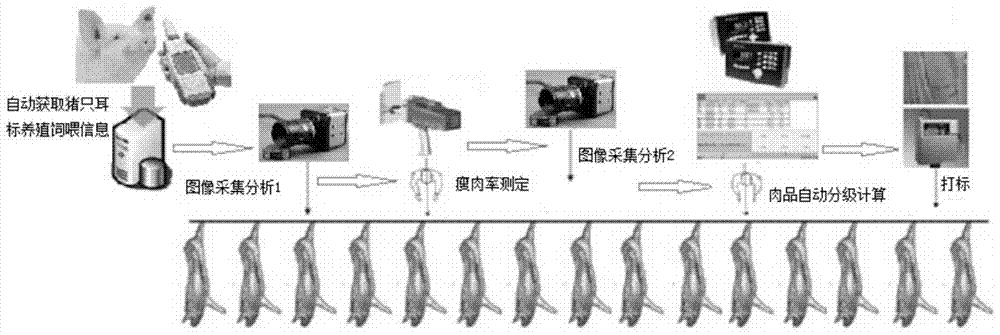

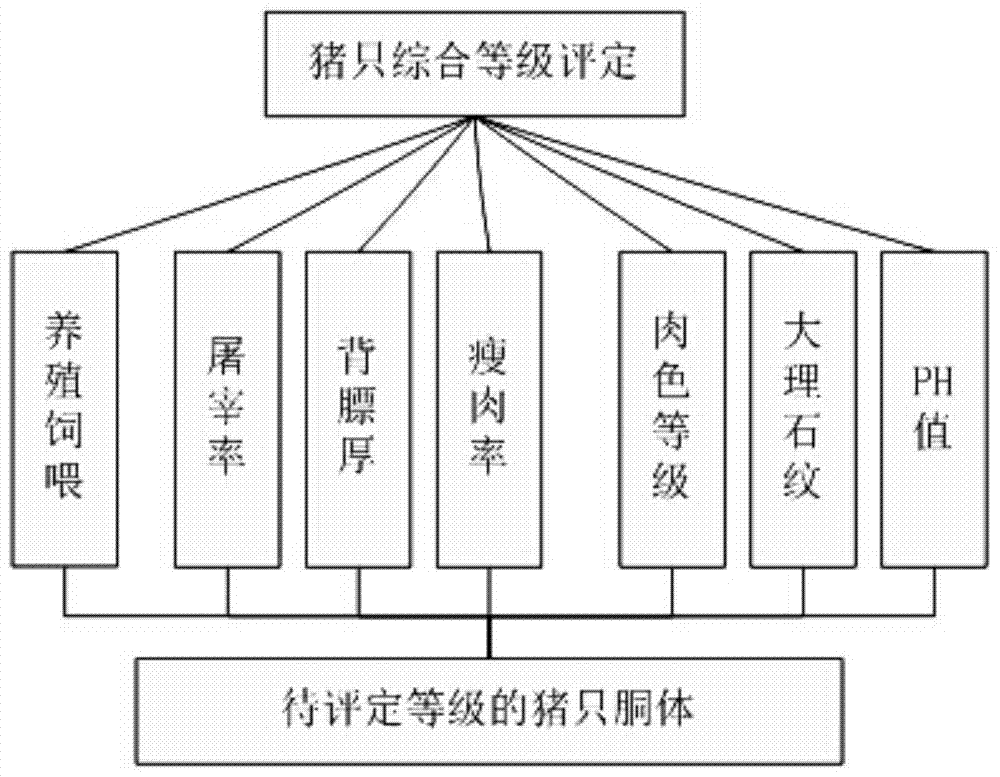

[0056] A multiple, refined and intelligent carcass meat grading method on an automatic pig slaughter line, the specific steps are as follows:

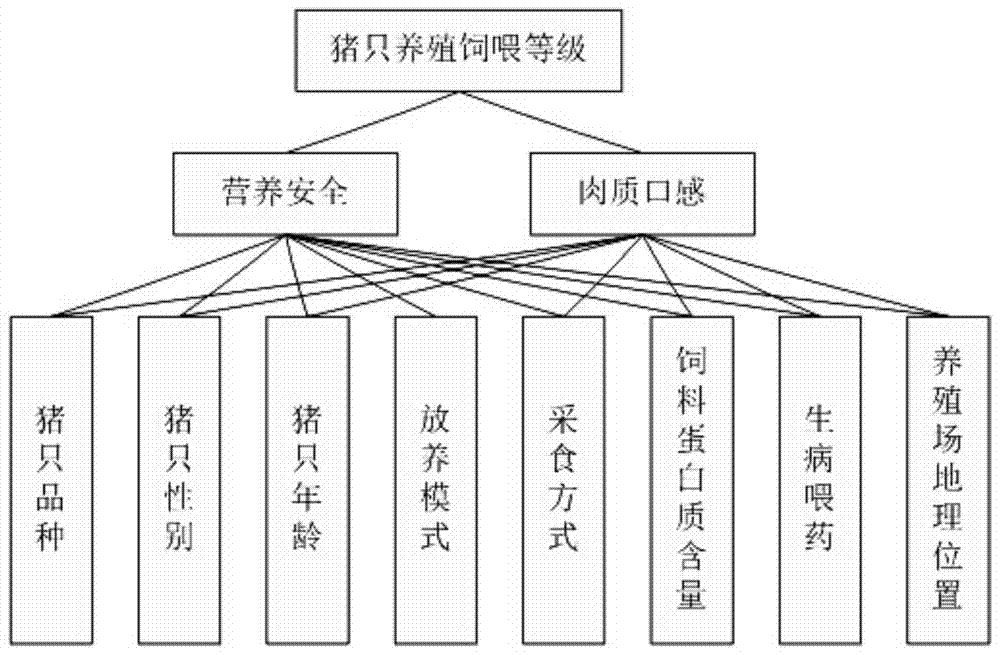

[0057] (1) Before slaughter, the pig ear tag information is read through the reading terminal for pig identification. The reading terminal sends the ear tag information to the information query system, and the information query system is in the pig farm According to the ear tag information of the pigs in the database, search for the historical breeding and feeding information recorded in the pig farm database during the breeding process of the corresponding pigs, including: pig breed, pig sex, age, stocking mode, feeding Method (whether ad libitum), protein content of feed, medicine for sickness, geographic location of farm. Extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com