Voltage transformer protection device

A technology of voltage transformers and protective devices, which is applied in the direction of inductors, transformers, transformer/inductor parts, etc., can solve the problem of increasing labor intensity and complexity, the failure of fuses to prompt information, and the inability to directly determine whether a fuse is blown, etc. problems, to achieve the effect of increasing labor intensity and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

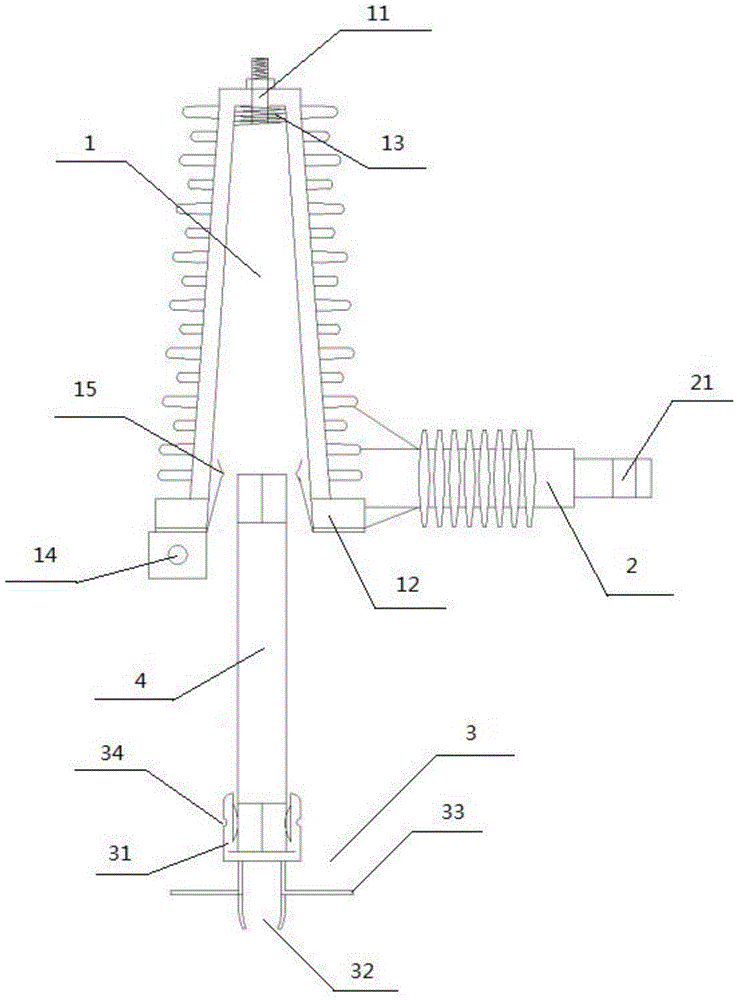

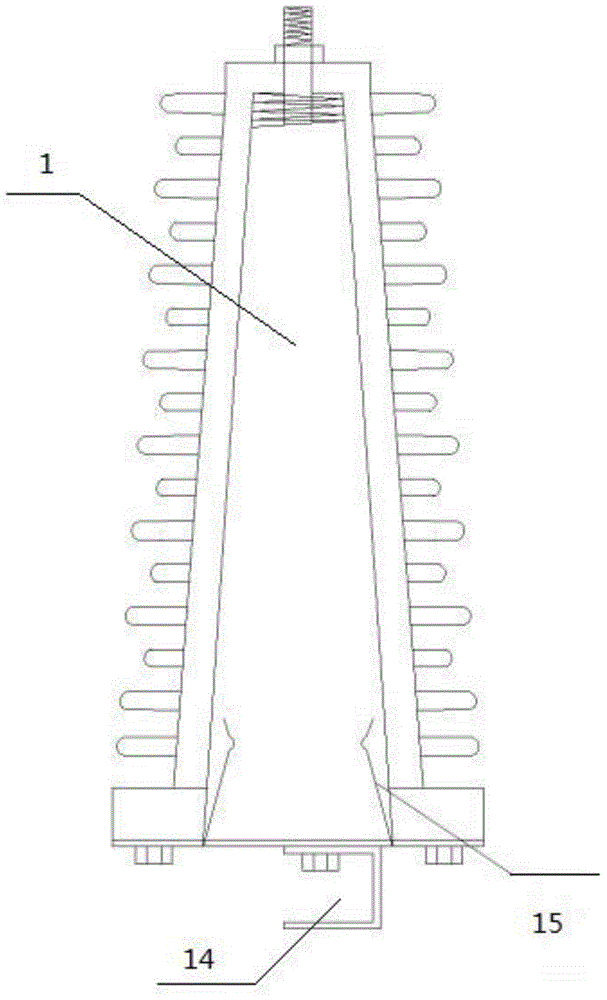

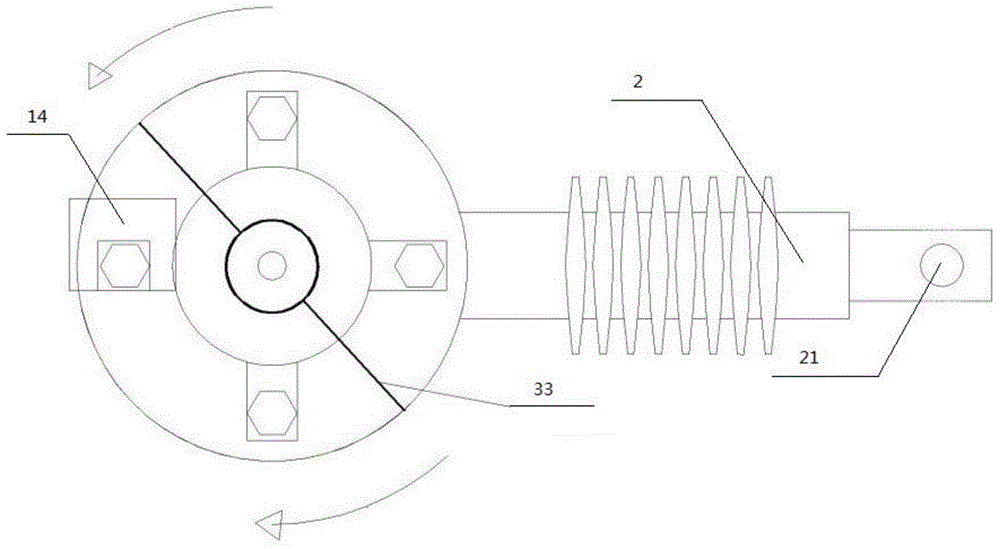

[0016] A voltage transformer protection device is characterized in that it includes an insulating cylinder 1, a mounting arm 2, and a high-voltage current-limiting fuse mounting base 3; the insulating cylinder 1 is a hollow cylindrical structure, and is evenly spaced from the lower outlet terminal 12 to the upper terminal 11. Thinner, the inner wall of the upper terminal 11 is provided with a contact buffer spring 13, the lower terminal 12 is provided with an anti-falling device 14, and the inner wall of the lower terminal 12 is provided with two fixed spring holders 15; the mounting arm 2 and the lower terminal of the insulating cylinder 12 are fixedly connected, and the installation arm 2 is provided with an installation fixing hole 21, which is used to fix the voltage transformer protection device; figure 2 As shown, the anti-falling device 14 is a frame-shaped structure with one end open.

[0017] The high-voltage current-limiting fuse installation base 3 includes a fuse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com