Wind turbine and its stator core and core module of the stator

A wind turbine and stator core technology, applied in the field of core modules, can solve the problems of weakening the content of the 5th and 7th harmonic magnetic field, increasing the volume and size of the generator, and exceeding the standard of vibration and noise of the generator, so as to improve the space Load back EMF wave, reduce no-load and load torque ripple, reduce vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

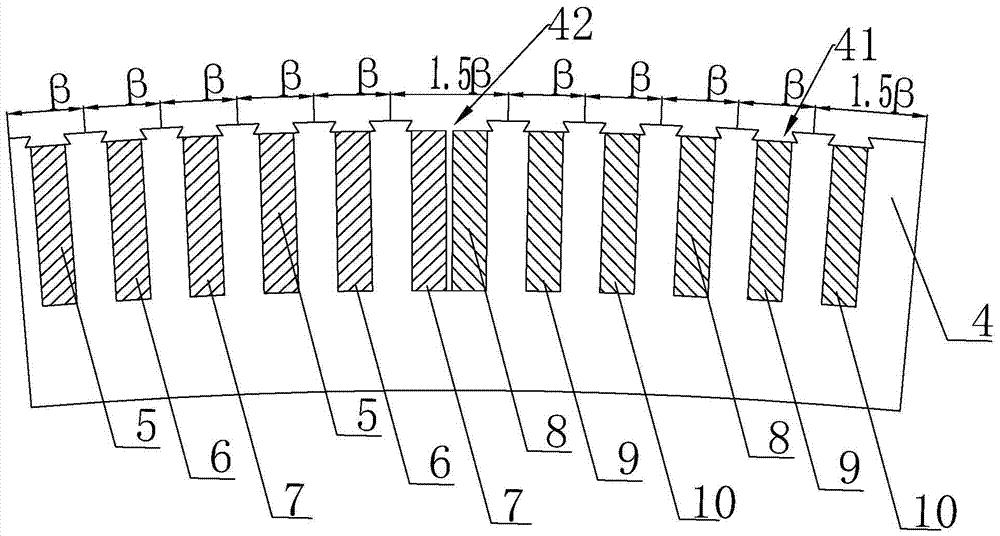

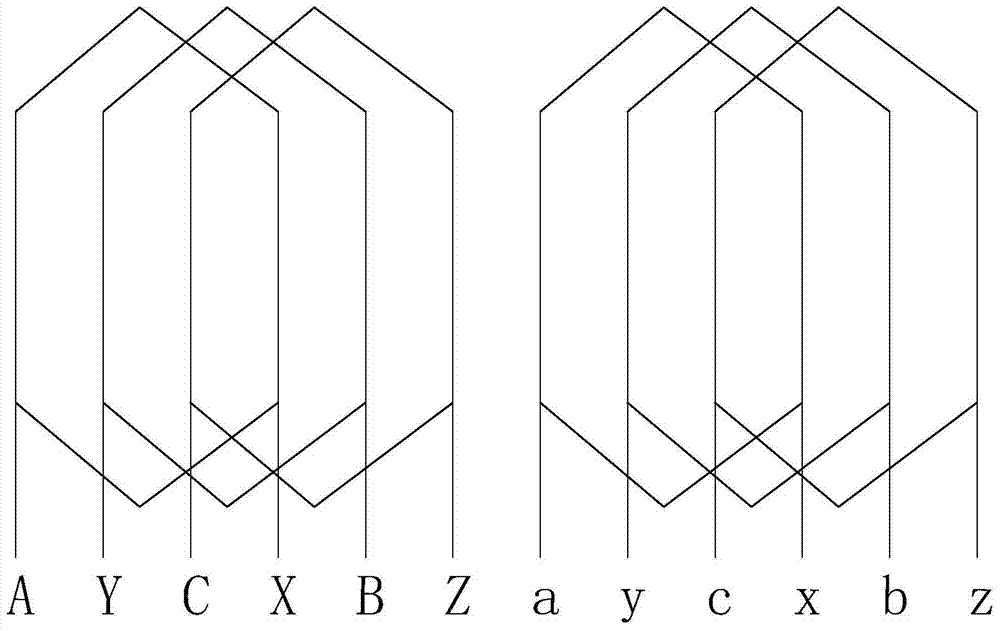

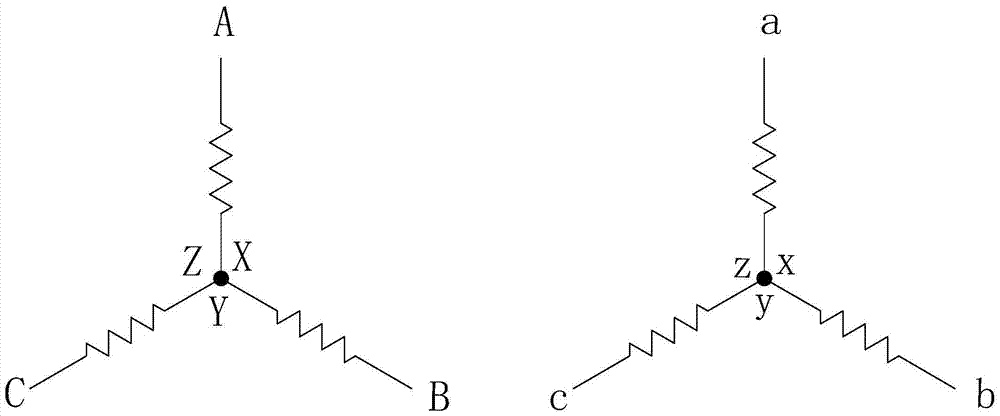

[0038] Such as figure 1 As shown in FIG. 1 , it is a schematic structural diagram of the core module of the stator according to Embodiment 1 of the present invention. The iron core module of the stator of the wind power generating set in the embodiment of the present invention, the overall size of the iron core module conforms to the principle that the number of slots per pole and each phase is q=1, and the iron core module is provided with two three-phase winding units, two three-phase winding units The electrical angle difference between them is 30 degrees.

[0039] Further, the core module 4 can have a plurality of slots for accommodating coils, each coil can be nested in two slots, and the slots can be divided into the first slot 41 for accommodating one coil side and the first slot for accommodating two coil sides The second alveolar 42. The number of the second slot 42 may be one, and may be arranged in the middle of the slot, and the number of the first slots 41 on th...

Embodiment 2

[0047] The present embodiment relates to a stator core composed of the core modules of the above embodiments and a wind power generator including the core.

[0048] After a certain number of the above-mentioned core modules are combined, the stator core of the embodiment of the present invention can be formed. Specifically, corresponding to the number of slots of the above-mentioned core modules, on the premise of adopting the design scheme of 432 slots on the circumference of the entire iron core, the number of core modules constituting the entire iron core can be 36, 18, 12, 9, 6, 4. Such as Figure 4 As shown, it is one of the structural schematic diagrams of the rotor poles of the embodiment of the present invention, and the entire stator core includes 36 such as figure 1 The core module 4 shown.

[0049] After the stator and the rotor including the above-mentioned stator core are assembled, the wind power generator according to the embodiment of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com