An array rice seedling machine

A kind of seedling seeding machine and array-type technology, applied in planting methods, transplanting machinery, applications, etc., can solve the problems of small sowing area, high cost of consumables and energy consumption, and seedlings falling downward, so as to increase the sowing area and increase the quantity Increased, distance compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

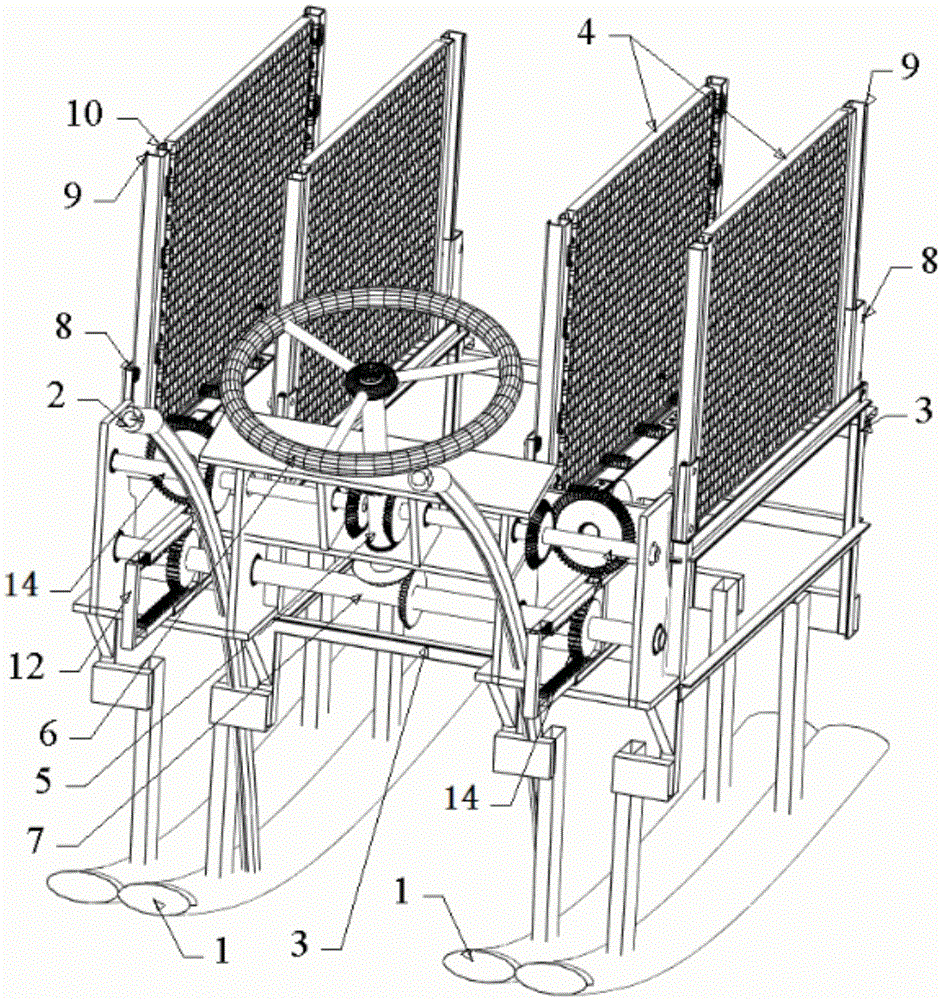

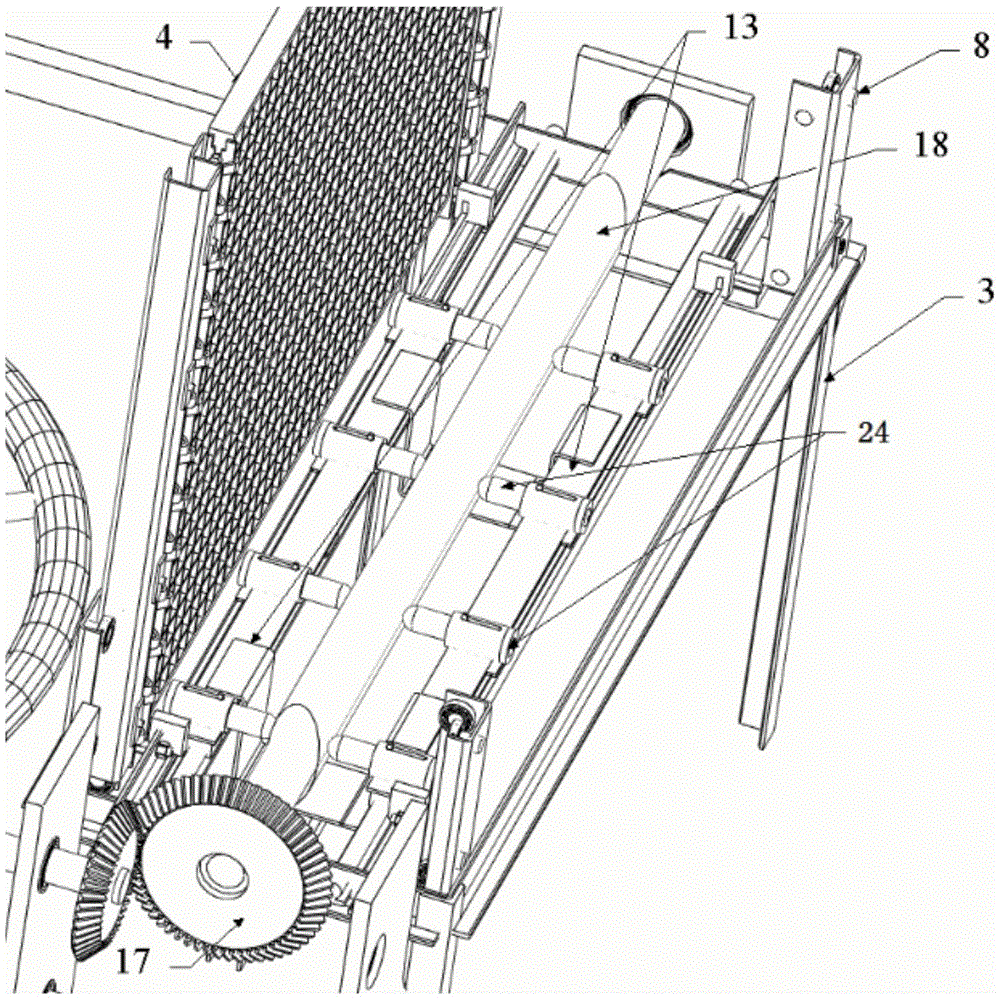

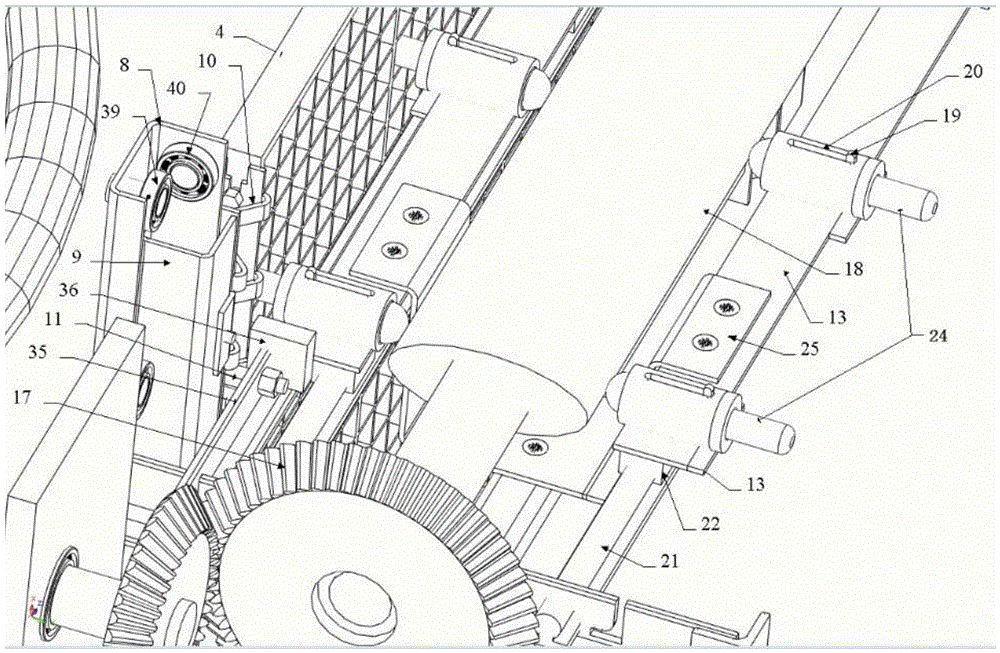

[0061] see figure 1 , The array rice seedling machine of the present embodiment includes a traveling mechanism and a frame 3 arranged on the traveling mechanism, and the frame 3 is provided with a seedling tray assembly and a seedling sowing mechanism. The seedling tray assembly includes a grid seedling tray 4 arranged on the frame 3 and perpendicular to the horizontal plane, a vertical guide mechanism arranged between the grid seedling tray 4 and the frame 3, and promoting the grid seedling tray 4 step by step. A step-down drive mechanism that moves downward. The seedling sowing mechanism includes a seedling ejecting needle 24, a seedling ejecting needle support 13, a seedling ejecting needle drive mechanism and a seedling ejecting needle support driving mechanism, wherein the seedling ejecting needle 24 is horizontally arranged on the seedling ejecting needle support 13, the The working end of the jacking needle 24 is facing the grid in the grid seedling tray 4; the driving...

Embodiment 2

[0084] see Figure 14 The difference between this embodiment and Embodiment 1 is that in this embodiment, the number of seedling-planting modules is four, and these four seedling-planting modules are arranged on the frame 3, wherein the two sides of the rotating shaft are respectively Two seedling-planting modules are set; a seedling-ejecting needle driving power mechanism is respectively arranged on both sides of the rotating shaft, and each seedling-ejecting needle-driving power mechanism drives the camshafts in the two seedling-planting modules to work; a seedling ejecting needle bracket is connected to the rotating shaft to drive In the power mechanism, the second transmission shaft in the power mechanism is driven by the jacking pin support to drive part of the gears in the four seedling-planting modules.

[0085] In this embodiment, other implementations other than the above are carried out with reference to Embodiment 1.

[0086] In the above-mentioned embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com