Convenient ultra-light model airplane power system

A model aircraft and power system technology, which is applied in toy aircraft, entertainment, toys, etc., can solve the problems that the overall model aircraft has a great influence on the weight, the waste of capacitor power, and the high accuracy required by the charger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

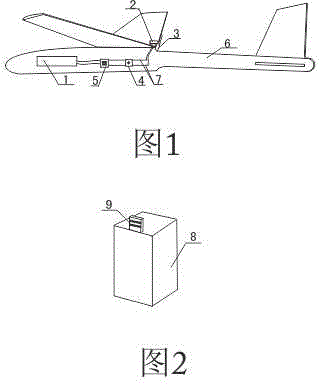

[0019] The embodiments created by the present invention are described in detail with the aid of the drawings. First install the motor (2) on the model airplane (6) according to the determined position, and install the propeller (3) and the motor (2) firmly. Install the power supply capacitor (1) according to the power supply installation position and connect with the power wire (7) For the motor (2) and the power supply capacitor (1), a normally closed control switch (4) is connected in series between the power wire (7) and between the power supply capacitor (1) and the control switch (4) of the power wire (7) Connect a charging head (5) in parallel, prepare a portable power bank (8) with a power supply capacitor (1) and a charging head (5) matching the portable power bank charging head (9), so that it has a convenient ultralight model aircraft power system The model airplane (6) is complete.

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com