Plastic bag crusher

A technology of plastic bags and pulverizers, which is applied in the direction of solid separation, separating solids from solids with airflow, grain processing, etc. It can solve problems such as not easy to crush, environmental hazards, and impact on the landscape, and achieve high work efficiency and crushing High efficiency and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

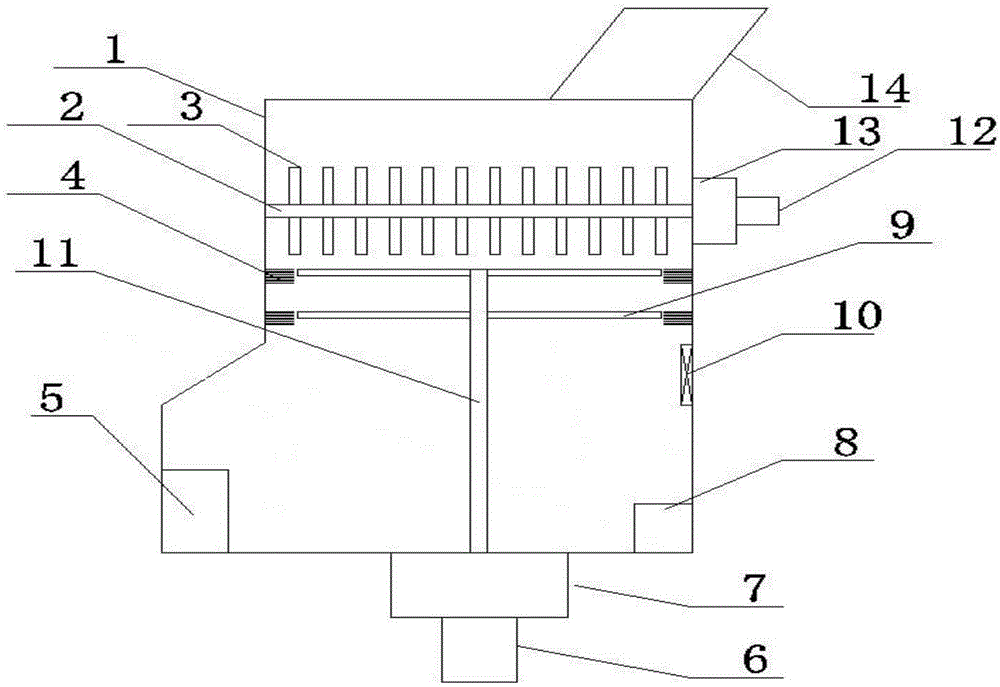

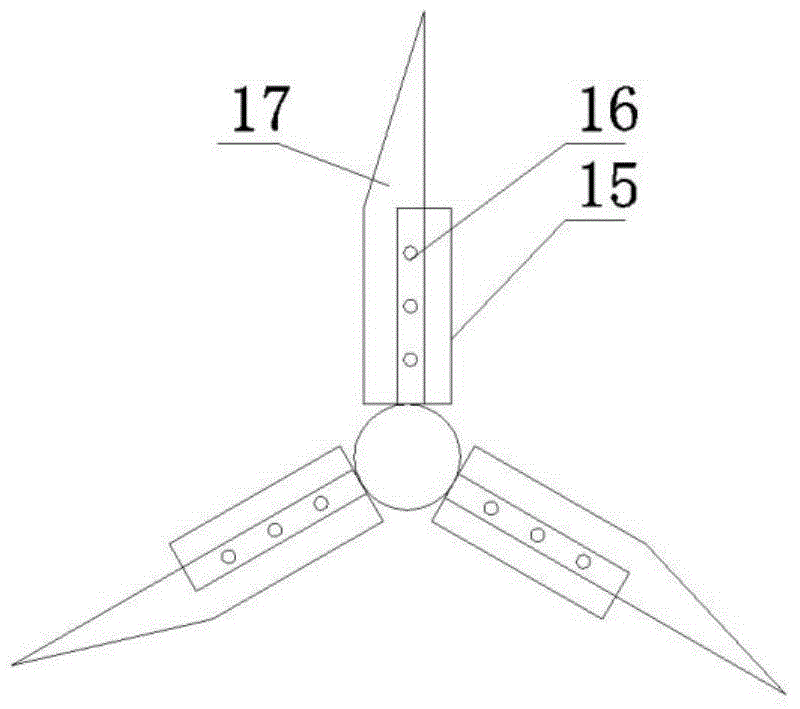

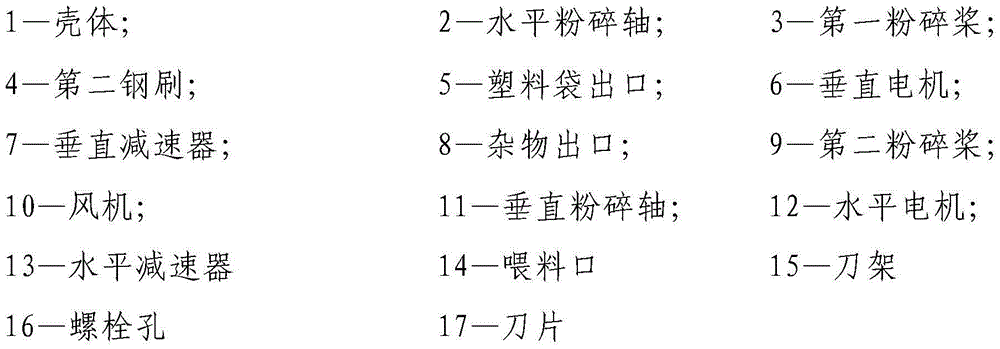

[0016] like figure 1 , figure 2 The shown plastic bag pulverizer includes a shell 1, a feeding port 14 is provided on one side of the top of the shell 1, and a horizontal pulverizing shaft 2 is rotatably installed on the upper side wall inside the shell 1. A plurality of first pulverizing paddles 3 are fixedly installed on the pulverizing shaft 2 in the direction perpendicular to the horizontal pulverizing shaft 2, and a plurality of first steel brushes are installed on the inner wall of the housing 1 along the circumferential direction of the first pulverizing paddles 3, and the horizontal pulverizing paddles are horizontally pulverized. One end of the shaft 2 extends to the outside of the housing 1 and is connected to the output shaft of the horizontal reducer 13, and the input shaft of the horizontal reducer 13 is connected to the output shaft of the horizontal motor 12; the horizontal crushing shaft located inside the housing 1 2 is provided with a vertical pulverizing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com