A real-time monitoring system and monitoring method for online operating parameters of a spark machine

A technology for real-time monitoring and operating parameters, which is applied to the online detection of spark machine voltage, temperature, liquid level, real-time monitoring system of spark machine online operating parameters and its monitoring, and current fields. It can solve the problem that the detection accuracy needs to be further improved and does not involve Digitized real-time monitoring system and other issues to achieve the effect of easy remote monitoring and management, high precision and stability, and good real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

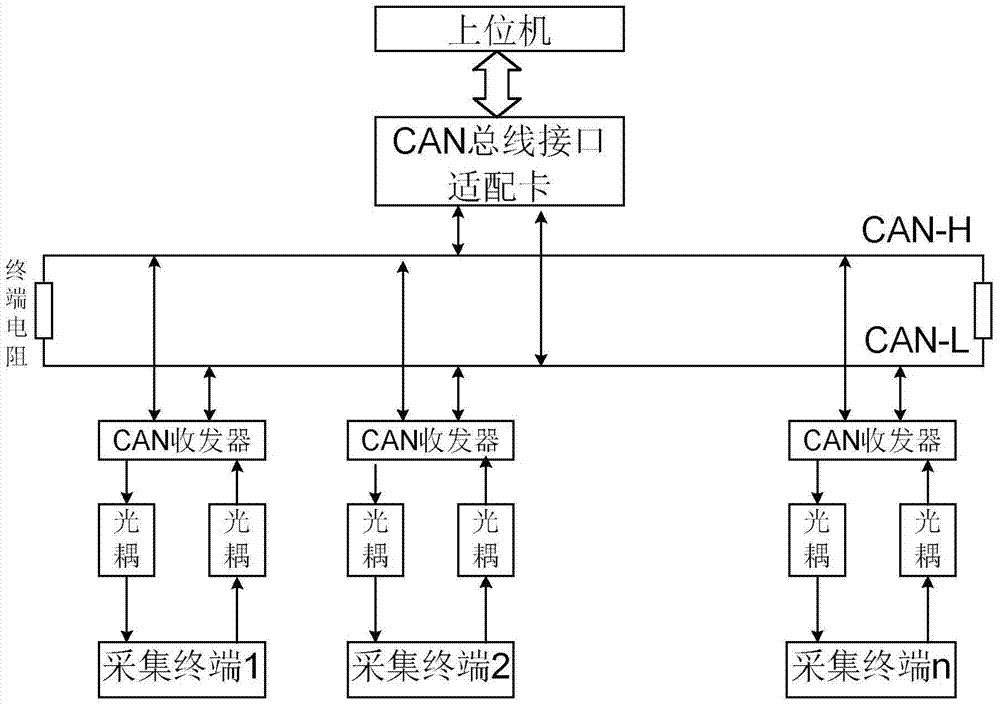

[0034] A real-time monitoring system for online operating parameters of a spark machine in this embodiment includes a collection terminal, a communication module, and a host computer. Such as figure 1 As shown, the communication module in this embodiment includes a microprocessor module with a built-in CAN controller, an optocoupler, a CAN transceiver, a CAN bus and a CAN bus interface adapter card, wherein: the input and output terminals of the CAN controller Connected to the input and output terminals of the optocoupler, the input and output terminals of the optocoupler are connected to the input and output terminals of the CAN transceiver, the CAN transceiver is connected to the CAN bus, and the CAN bus is adapted through the CAN bus interface The card is connected with the upper computer. Specifically, in this embodiment, the optocoupler is a 6N137 high-speed optocoupler, and the CAN transceiver is a TJA1050 high-speed CAN transceiver.

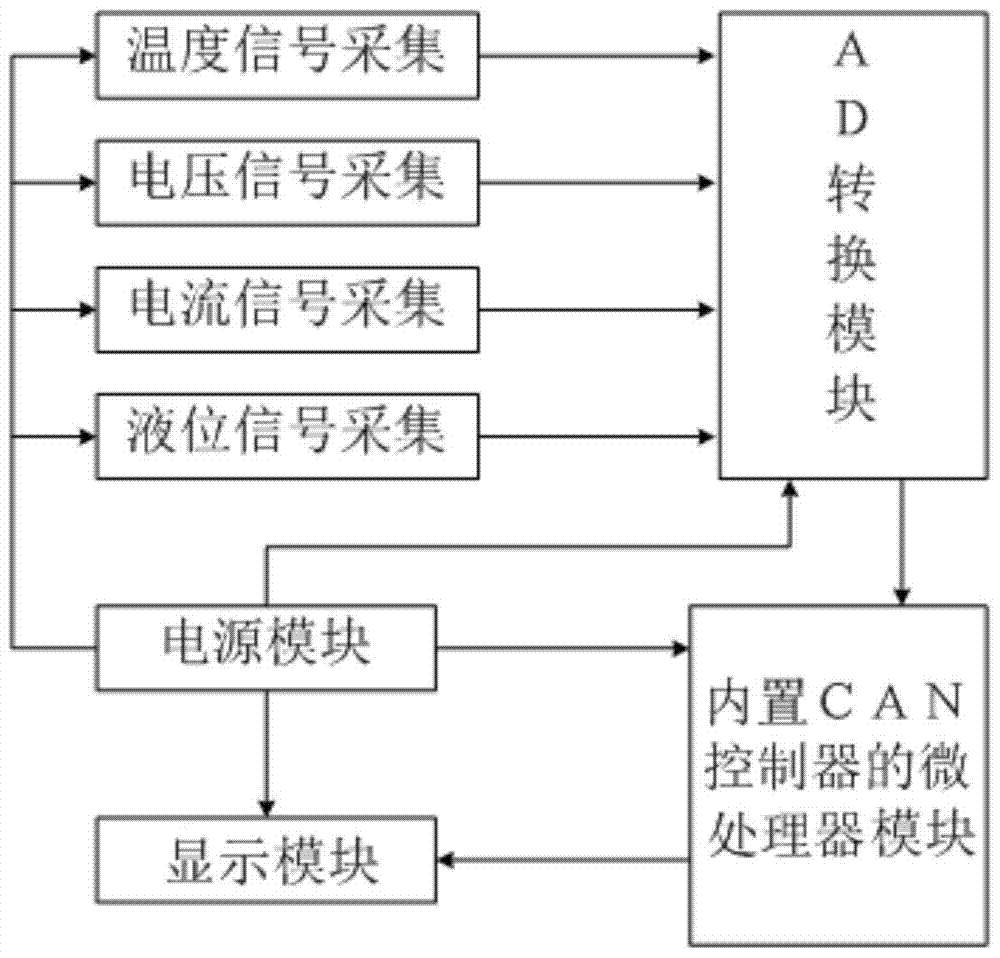

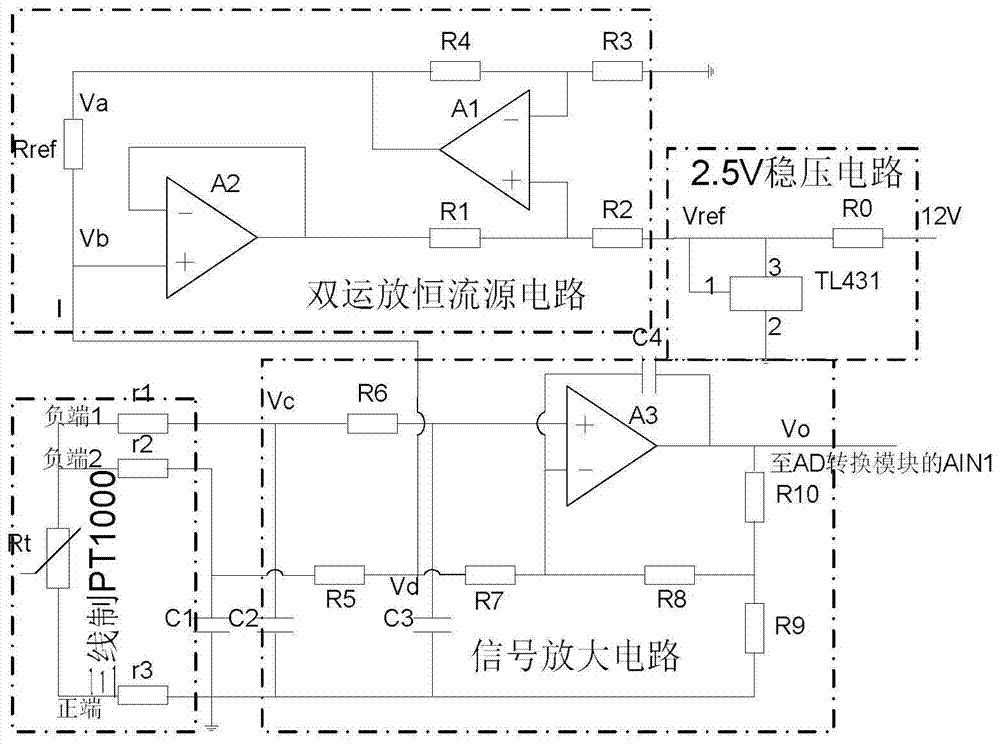

[0035] Such as figure 2 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com