rolling tool

A rolling and tooling technology, used in manufacturing tools, metal processing equipment, metal material coating processes, etc., can solve problems such as offset and coating surface separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

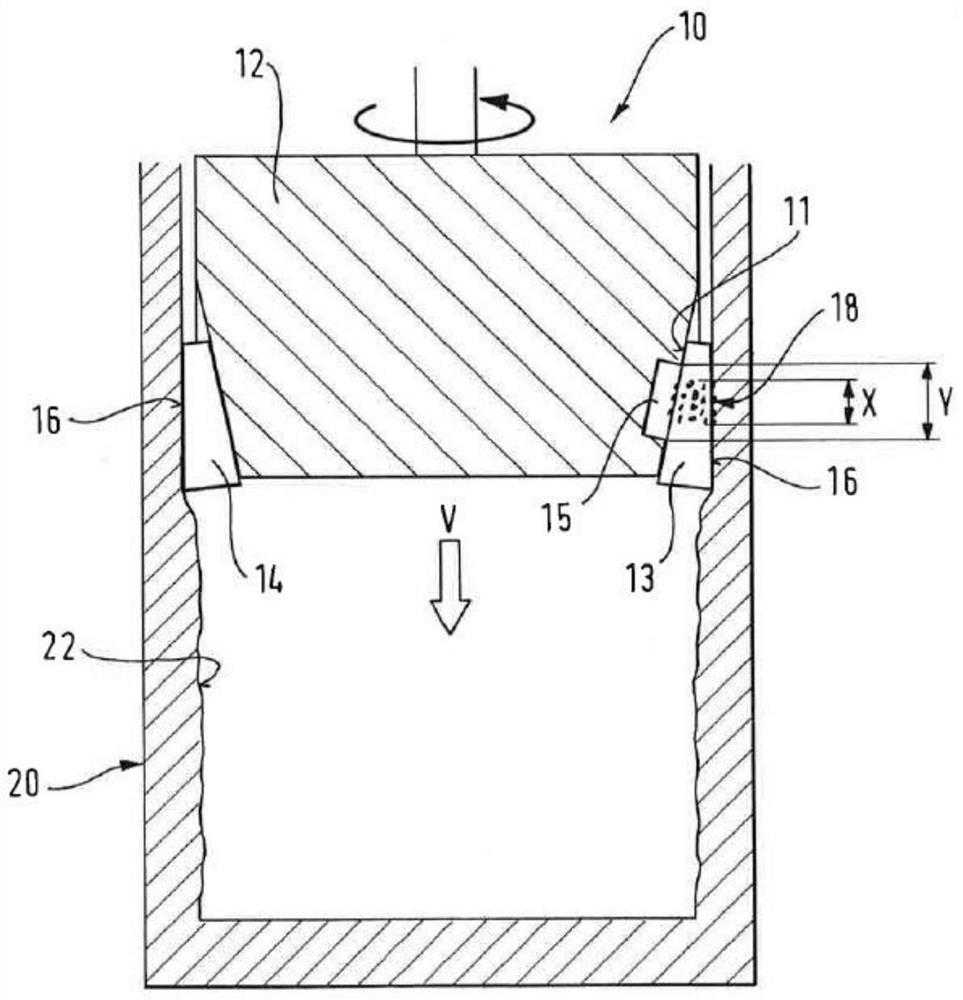

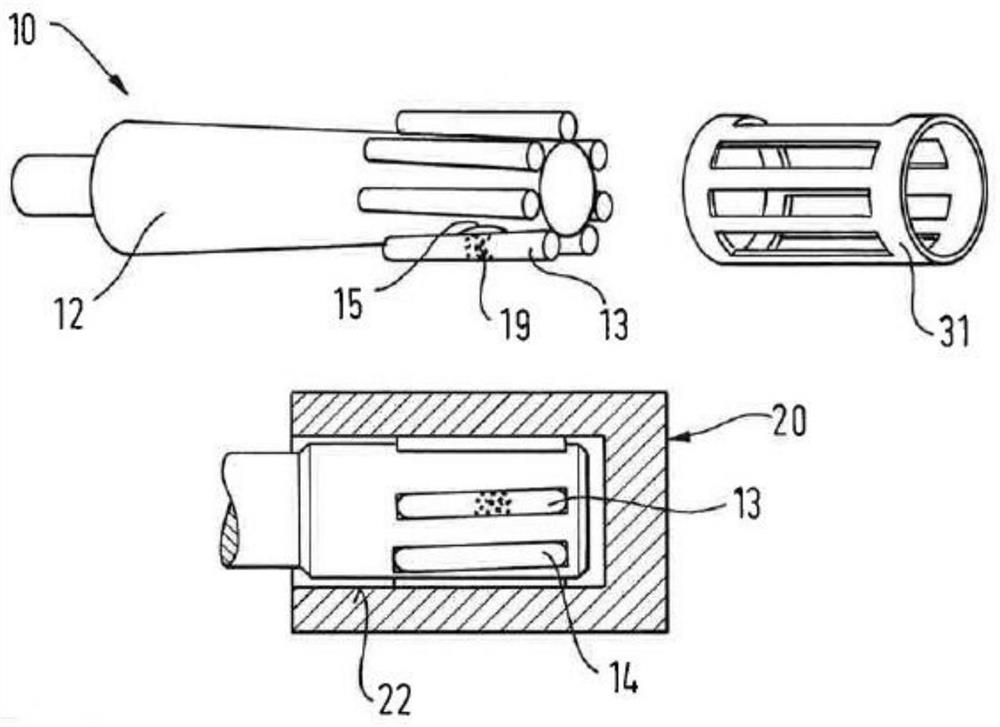

[0034] figure 1 A schematic side view of a first embodiment of a rolling tool 10 according to the invention is shown. The rolling tool is passing through the substantially cylindrical section of the tubular workpiece 20 in the feed direction and simultaneously rotates about its own axis. For this purpose, the rolling tool can be clamped by means of rollers or similar. Of course, the rolling tool can optionally also be fixedly clamped, while the workpiece is moved rotatably toward the rolling tool 10 .

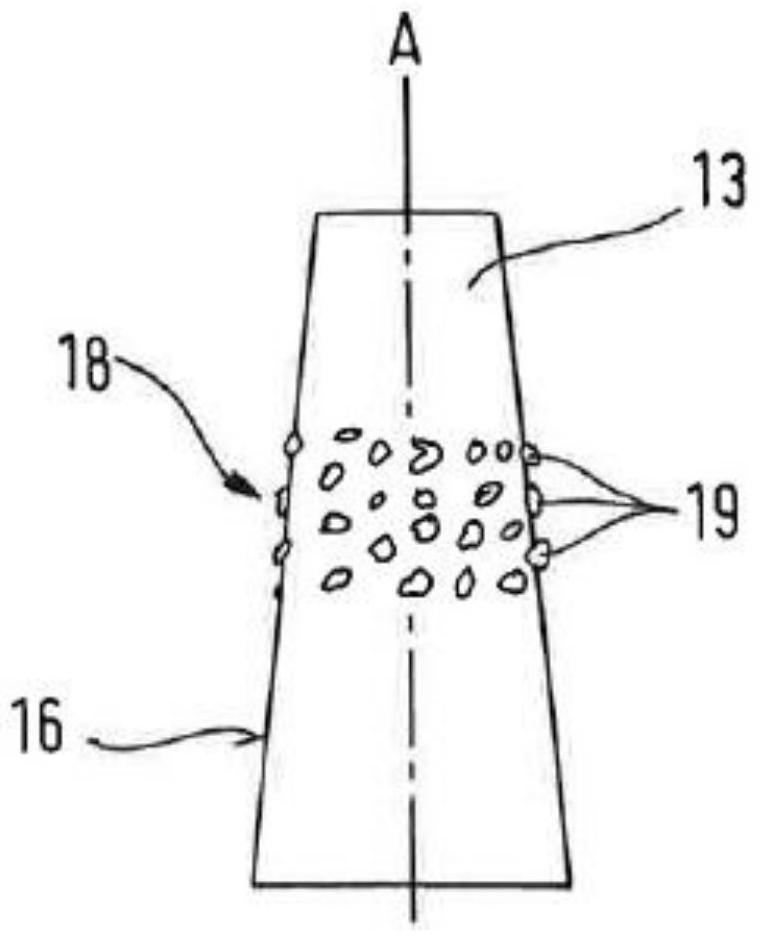

[0035] Before machining, the outer diameter of the rolling tool is slightly larger than the inner diameter of the workpiece 20, so that the machined inner surface 22 of the workpiece 20 is plastically deformed and strengthened radially outward during machining. Unlike conventional rolling tools, however, the inner wall of the workpiece 20 is not completely smoothed, but is roughened by the protrusions 19 of the rolling tool 10 .

[0036] The rolling tool 10 has a rotatably m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com